What is Global Automated Warehouse Systems Market?

The Global Automated Warehouse Systems Market refers to the industry focused on the development and implementation of advanced technologies that automate various processes within warehouses. These systems are designed to improve efficiency, accuracy, and productivity by minimizing human intervention in tasks such as sorting, storing, retrieving, and managing inventory. Automated warehouse systems encompass a wide range of technologies, including robotics, conveyor systems, automated storage and retrieval systems (AS/RS), and warehouse management software. The market is driven by the increasing demand for faster and more efficient supply chain operations, the need to reduce labor costs, and the growing complexity of warehouse operations due to the rise of e-commerce. As businesses strive to meet customer expectations for quick and accurate deliveries, the adoption of automated solutions is becoming increasingly essential. These systems not only enhance operational efficiency but also provide valuable data insights that help in optimizing warehouse management and decision-making processes. The global market for automated warehouse systems is witnessing significant growth as companies across various industries recognize the benefits of automation in maintaining a competitive edge in the rapidly evolving business landscape.

Mini-Load Systems, Tray Warehouses, Pallet Warehouses in the Global Automated Warehouse Systems Market:

Mini-Load Systems, Tray Warehouses, and Pallet Warehouses are integral components of the Global Automated Warehouse Systems Market, each serving distinct functions tailored to specific storage and retrieval needs. Mini-Load Systems are designed for handling small to medium-sized items, typically stored in bins or trays. These systems are ideal for environments where high-speed picking and precision are crucial, such as in e-commerce and retail sectors. Mini-Load Systems utilize automated cranes or shuttles to efficiently retrieve items from storage racks, significantly reducing the time and labor required for order fulfillment. The compact design of these systems allows for optimal use of vertical space, making them suitable for facilities with limited floor area. Tray Warehouses, on the other hand, focus on the storage and retrieval of items placed on trays. These systems are particularly beneficial for industries that require the handling of delicate or irregularly shaped products, such as pharmaceuticals or electronics. Tray Warehouses employ automated systems to transport trays to and from storage locations, ensuring gentle handling and minimizing the risk of damage. The flexibility of tray systems allows for easy adaptation to changing inventory requirements, making them a versatile solution for dynamic warehouse environments. Pallet Warehouses are designed for the storage and handling of large, heavy items typically stored on pallets. These systems are prevalent in industries such as manufacturing, food and beverage, and logistics, where bulk storage and efficient movement of goods are essential. Automated Pallet Warehouses utilize technologies such as automated guided vehicles (AGVs) and robotic palletizers to streamline the storage and retrieval process. By automating the handling of pallets, these systems enhance safety, reduce labor costs, and improve overall operational efficiency. The integration of advanced software solutions in Pallet Warehouses enables real-time tracking and management of inventory, providing valuable insights for optimizing supply chain operations. Each of these systems plays a crucial role in the broader landscape of automated warehouse solutions, offering tailored benefits that address the unique challenges faced by different industries. As businesses continue to seek ways to enhance efficiency and reduce operational costs, the adoption of Mini-Load Systems, Tray Warehouses, and Pallet Warehouses is expected to grow, driving further innovation and development in the Global Automated Warehouse Systems Market.

Energy, Transport/Logistics, Healthcare, Retail, Manufacturing, Other in the Global Automated Warehouse Systems Market:

The usage of Global Automated Warehouse Systems Market spans across various sectors, each leveraging automation to enhance efficiency and productivity. In the Energy sector, automated warehouse systems are employed to manage the storage and distribution of equipment and materials used in energy production and distribution. These systems ensure the timely availability of critical components, reducing downtime and improving operational efficiency. In the Transport and Logistics sector, automated systems streamline the handling and movement of goods, facilitating faster and more accurate deliveries. By automating processes such as sorting, packing, and loading, logistics companies can significantly reduce labor costs and improve service levels. The Healthcare industry benefits from automated warehouse systems by ensuring the safe and efficient storage and retrieval of medical supplies and pharmaceuticals. Automation minimizes the risk of human error, enhances inventory accuracy, and ensures compliance with stringent regulatory requirements. In the Retail sector, automated systems enable retailers to manage high volumes of inventory efficiently, supporting the rapid fulfillment of online orders and improving customer satisfaction. The Manufacturing industry utilizes automated warehouse systems to optimize the storage and movement of raw materials and finished goods, enhancing production efficiency and reducing lead times. Other sectors, such as food and beverage, electronics, and automotive, also leverage automated warehouse systems to address specific operational challenges and improve overall supply chain performance. The versatility and adaptability of automated warehouse solutions make them an invaluable asset across diverse industries, driving the continued growth and evolution of the Global Automated Warehouse Systems Market.

Global Automated Warehouse Systems Market Outlook:

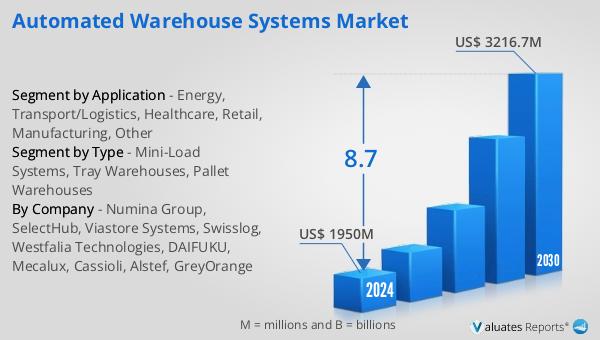

The outlook for the Global Automated Warehouse Systems Market indicates a promising trajectory of growth. According to market analysis, the market is anticipated to expand from a valuation of US$ 1950 million in 2024 to approximately US$ 3216.7 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 8.7% over the forecast period. This upward trend reflects the increasing adoption of automated solutions across various industries as businesses seek to enhance operational efficiency, reduce costs, and improve service delivery. The demand for automated warehouse systems is driven by the need to address the challenges posed by the rapid growth of e-commerce, the complexity of modern supply chains, and the rising expectations of consumers for fast and accurate deliveries. As companies continue to invest in automation technologies to remain competitive, the market for automated warehouse systems is poised for significant expansion. The integration of advanced technologies such as robotics, artificial intelligence, and data analytics is expected to further drive innovation and development in this market, offering new opportunities for growth and transformation. The Global Automated Warehouse Systems Market is set to play a pivotal role in shaping the future of supply chain management, providing businesses with the tools they need to thrive in an increasingly dynamic and competitive environment.

| Report Metric | Details |

| Report Name | Automated Warehouse Systems Market |

| Accounted market size in 2024 | US$ 1950 million |

| Forecasted market size in 2030 | US$ 3216.7 million |

| CAGR | 8.7 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Numina Group, SelectHub, Viastore Systems, Swisslog, Westfalia Technologies, DAIFUKU, Mecalux, Cassioli, Alstef, GreyOrange |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |