What is Global Strain Measuring Instrument Market?

The Global Strain Measuring Instrument Market is a specialized sector focused on devices that measure strain, which is the deformation or displacement of material that results from an applied force. These instruments are crucial in various fields, including engineering, construction, and manufacturing, as they help in assessing the structural integrity and performance of materials and components. The market encompasses a range of products, from simple mechanical devices to advanced electronic systems, each designed to provide precise measurements under different conditions. The demand for strain measuring instruments is driven by the need for accurate data in research and development, quality control, and safety assurance. As industries continue to innovate and push the boundaries of material science, the importance of reliable strain measurement tools becomes even more pronounced. This market is characterized by continuous technological advancements, with manufacturers striving to offer more accurate, durable, and user-friendly instruments. The global reach of this market is evident as these instruments are utilized in various applications worldwide, reflecting the universal need for precise measurement in ensuring the safety and efficiency of structures and machinery.

Dynamic Measuring Gauge, Static Measuring Gauge in the Global Strain Measuring Instrument Market:

Dynamic Measuring Gauges and Static Measuring Gauges are two primary types of instruments within the Global Strain Measuring Instrument Market, each serving distinct purposes based on the nature of the strain being measured. Dynamic Measuring Gauges are designed to capture strain data in environments where the force or load is changing rapidly. These gauges are essential in applications where materials or structures are subjected to fluctuating forces, such as in automotive crash testing, aerospace component testing, and dynamic load analysis in civil engineering. They are equipped with high-speed data acquisition systems that can record transient events with great precision, allowing engineers to analyze the behavior of materials under dynamic conditions. The technology behind dynamic gauges often involves advanced sensors and signal processing techniques to ensure accurate and reliable data capture even in the most challenging environments. On the other hand, Static Measuring Gauges are used in scenarios where the strain is constant or changes very slowly over time. These gauges are ideal for monitoring the long-term deformation of structures, such as bridges, buildings, and pipelines, where the primary concern is the gradual accumulation of strain due to static loads. Static gauges are typically more robust and require less frequent calibration compared to their dynamic counterparts, making them suitable for long-term monitoring applications. They often employ technologies such as foil strain gauges, fiber optic sensors, or vibrating wire sensors, each offering unique advantages in terms of sensitivity, range, and environmental resistance. The choice between dynamic and static measuring gauges depends largely on the specific requirements of the application, including the expected strain rates, environmental conditions, and the level of precision needed. Both types of gauges play a critical role in ensuring the safety and reliability of structures and materials across various industries. As technology advances, the integration of digital interfaces, wireless communication, and data analytics is becoming increasingly common in both dynamic and static measuring gauges, enhancing their functionality and ease of use. This evolution is driven by the growing demand for real-time data and remote monitoring capabilities, which are becoming essential in modern engineering and industrial applications. The Global Strain Measuring Instrument Market continues to evolve, with manufacturers focusing on developing innovative solutions that meet the diverse needs of their customers while maintaining high standards of accuracy and reliability.

Scientific Experiment, Industrial Equipment Monitoring, Electrical Industry, Transportation, Other in the Global Strain Measuring Instrument Market:

The usage of Global Strain Measuring Instruments spans across various fields, each benefiting from the precise data these instruments provide. In scientific experiments, strain measuring instruments are indispensable for understanding material properties and behaviors under different conditions. Researchers rely on these tools to gather accurate data that can lead to breakthroughs in material science, physics, and engineering. The ability to measure strain precisely allows scientists to validate theoretical models and develop new materials with enhanced properties. In industrial equipment monitoring, strain gauges are used to ensure the safety and efficiency of machinery. By continuously monitoring the strain on critical components, maintenance teams can predict failures before they occur, reducing downtime and preventing costly accidents. This proactive approach to maintenance is particularly valuable in industries such as manufacturing, where equipment reliability is paramount. In the electrical industry, strain measuring instruments are used to monitor the mechanical stress on electrical components and systems. This is crucial for ensuring the longevity and performance of electrical infrastructure, as excessive strain can lead to failures and power outages. By providing real-time data on the condition of electrical components, strain gauges help in optimizing maintenance schedules and improving the overall reliability of the electrical grid. In the transportation sector, strain measuring instruments are used to assess the structural integrity of vehicles, bridges, and other infrastructure. By monitoring the strain on these structures, engineers can ensure they are safe for use and identify any potential issues before they become critical. This is particularly important in the context of aging infrastructure, where regular monitoring is essential to prevent catastrophic failures. Beyond these specific applications, strain measuring instruments are also used in a variety of other fields, including construction, aerospace, and medical research. In each of these areas, the ability to measure strain accurately is crucial for ensuring the safety, performance, and reliability of materials and structures. As technology continues to advance, the capabilities of strain measuring instruments are expanding, offering new opportunities for innovation and improvement across a wide range of industries.

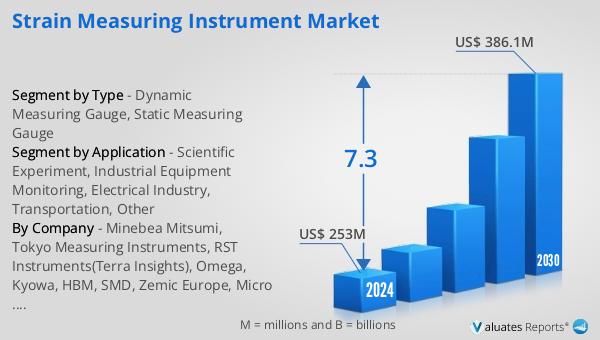

Global Strain Measuring Instrument Market Outlook:

The outlook for the Global Strain Measuring Instrument Market indicates a promising growth trajectory. The market is anticipated to expand from a valuation of US$ 253 million in 2024 to approximately US$ 386.1 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 7.3% over the forecast period. This upward trend reflects the increasing demand for precise and reliable strain measurement tools across various industries. As sectors such as construction, aerospace, and manufacturing continue to evolve, the need for accurate data on material behavior and structural integrity becomes more critical. The growth in this market is also driven by technological advancements that enhance the functionality and ease of use of strain measuring instruments. Innovations such as digital interfaces, wireless communication, and advanced data analytics are becoming integral features of modern strain gauges, making them more versatile and user-friendly. Additionally, the growing emphasis on safety and quality assurance in industrial processes is fueling the demand for these instruments. As companies strive to improve their products and services, the role of strain measuring instruments in ensuring the reliability and performance of materials and structures becomes increasingly important. This market outlook underscores the vital role that strain measuring instruments play in supporting innovation and safety across a wide range of applications.

| Report Metric | Details |

| Report Name | Strain Measuring Instrument Market |

| Accounted market size in 2024 | US$ 253 million |

| Forecasted market size in 2030 | US$ 386.1 million |

| CAGR | 7.3 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Minebea Mitsumi, Tokyo Measuring Instruments, RST Instruments(Terra Insights), Omega, Kyowa, HBM, SMD, Zemic Europe, Micro Measurements, NI, Althen, Matest, Soil Instruments, MICRO EPSILON, Sigmar Technology, Haiying Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |