What is Global Strain Measuring Gage Market?

The Global Strain Measuring Gage Market is a specialized segment within the broader field of measurement and instrumentation. Strain gages are devices used to measure the amount of deformation or strain in an object. They are essential tools in various industries for ensuring structural integrity and safety. The market for these devices is driven by the increasing demand for precision in measuring stress and strain in materials, which is crucial for quality control and safety assurance in manufacturing, construction, and other sectors. The global market encompasses a wide range of strain gages, including those designed for specific applications and environments. These devices are used in scientific research, industrial control, and various engineering applications to monitor and analyze the physical changes in materials under stress. As industries continue to advance technologically, the need for accurate and reliable strain measurement tools is expected to grow, making the Global Strain Measuring Gage Market a vital component of modern industrial and scientific practices.

Linear Strain Gage, T-shaped Strain Gage, V-shaped Strain Gage, Chains Strain Gage, Full Bridge Strain Gage, Others in the Global Strain Measuring Gage Market:

In the Global Strain Measuring Gage Market, several types of strain gages are utilized, each designed for specific applications and measurement needs. Linear strain gages are the most common type, used to measure strain in a single direction. They are typically used in applications where the primary concern is the elongation or compression of a material along a single axis. T-shaped strain gages, on the other hand, are designed to measure strain in two perpendicular directions. This makes them ideal for applications where multi-directional stress analysis is required, such as in complex structures or materials that experience stress from multiple angles. V-shaped strain gages are similar to T-shaped gages but are designed to measure strain at an angle, providing a more comprehensive analysis of stress distribution in a material. Chains strain gages consist of multiple gages arranged in a series, allowing for the measurement of strain over a larger area or along a specific path. This type of gage is particularly useful in applications where the strain distribution is not uniform or where multiple points of measurement are required. Full bridge strain gages are used in applications that require high precision and accuracy. They consist of four strain gages arranged in a Wheatstone bridge configuration, which allows for the cancellation of temperature effects and increases the sensitivity of the measurement. This makes them ideal for applications where environmental conditions can affect the accuracy of the measurement, such as in outdoor or high-temperature environments. Other types of strain gages include those designed for specific materials or applications, such as high-temperature gages, waterproof gages, and gages designed for use in corrosive environments. Each type of strain gage has its own unique advantages and is chosen based on the specific requirements of the application. The diversity of strain gages available in the market ensures that there is a suitable solution for virtually any strain measurement need, making them an essential tool in a wide range of industries.

Scientific Experiment, Industrial Control, Electrical Industry, Transportation, Other in the Global Strain Measuring Gage Market:

The Global Strain Measuring Gage Market finds extensive usage across various fields, each with its unique requirements and applications. In scientific experiments, strain gages are used to measure the deformation of materials under different conditions, providing valuable data for research and development. They are essential in experiments that require precise measurements of stress and strain, such as those conducted in material science, physics, and engineering. The data obtained from these measurements can be used to develop new materials, improve existing ones, and enhance our understanding of the physical properties of materials. In industrial control, strain gages are used to monitor the structural integrity of machinery and equipment. They provide real-time data on the stress and strain experienced by components, allowing for timely maintenance and preventing potential failures. This is particularly important in industries where equipment failure can lead to significant downtime or safety hazards, such as in manufacturing, construction, and aerospace. In the electrical industry, strain gages are used to measure the mechanical stress on electrical components, ensuring their reliability and performance. They are used in the design and testing of electrical devices, such as transformers, circuit breakers, and connectors, to ensure that they can withstand the mechanical stresses they will encounter in operation. In transportation, strain gages are used to monitor the structural integrity of vehicles and infrastructure. They are used in the design and testing of vehicles, such as cars, airplanes, and trains, to ensure that they can withstand the stresses of operation. They are also used in the monitoring of infrastructure, such as bridges and tunnels, to ensure their safety and reliability. Other applications of strain gages include their use in the medical field, where they are used to measure the strain on medical devices and implants, and in the sports industry, where they are used to analyze the performance of athletes and equipment. The versatility and precision of strain gages make them an invaluable tool in a wide range of applications, ensuring the safety, reliability, and performance of materials and structures.

Global Strain Measuring Gage Market Outlook:

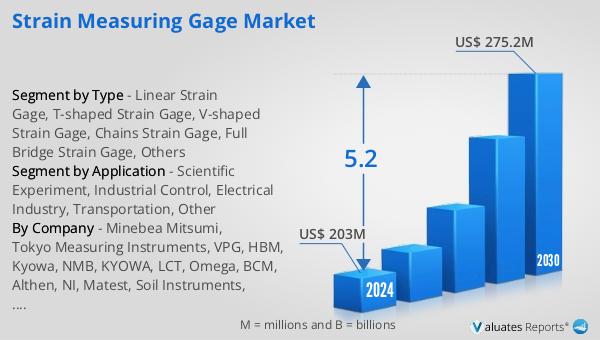

The outlook for the Global Strain Measuring Gage Market is promising, with projections indicating significant growth in the coming years. The market is expected to expand from a valuation of US$ 203 million in 2024 to approximately US$ 275.2 million by 2030. This growth represents a Compound Annual Growth Rate (CAGR) of 5.2% over the forecast period. This anticipated increase in market size is driven by the growing demand for precise and reliable strain measurement tools across various industries. As technological advancements continue to drive innovation in manufacturing, construction, and other sectors, the need for accurate strain measurement becomes increasingly critical. The ability to monitor and analyze the physical changes in materials under stress is essential for ensuring quality control, safety, and performance. Additionally, the increasing focus on research and development in material science and engineering further fuels the demand for advanced strain gages. As industries strive to enhance their products and processes, the role of strain gages in providing valuable data and insights becomes even more crucial. This positive market outlook underscores the importance of strain gages in modern industrial and scientific practices, highlighting their continued relevance and necessity in a rapidly evolving technological landscape.

| Report Metric | Details |

| Report Name | Strain Measuring Gage Market |

| Accounted market size in 2024 | US$ 203 million |

| Forecasted market size in 2030 | US$ 275.2 million |

| CAGR | 5.2 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Minebea Mitsumi, Tokyo Measuring Instruments, VPG, HBM, Kyowa, NMB, KYOWA, LCT, Omega, BCM, Althen, NI, Matest, Soil Instruments, MICRO EPSILON, Binsfeld |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |