What is Global Radiofrequency Thawing Equipment Market?

The Global Radiofrequency Thawing Equipment Market is a specialized segment within the broader food processing and preservation industry. This market focuses on the use of radiofrequency technology to thaw frozen food products efficiently and uniformly. Radiofrequency thawing equipment utilizes electromagnetic waves to generate heat within the food, allowing for a faster and more even thawing process compared to traditional methods like air or water thawing. This technology is particularly beneficial for industries that require rapid thawing to maintain the quality and safety of food products, such as meat, poultry, seafood, and even fruits and vegetables. The equipment is designed to handle various sizes and types of food products, making it versatile for different industrial applications. As the demand for high-quality, safe, and quickly processed food continues to rise, the Global Radiofrequency Thawing Equipment Market is expected to grow, driven by advancements in technology and increasing awareness of food safety standards. This market is characterized by continuous innovation and the development of more efficient and user-friendly equipment, catering to the needs of food processors worldwide.

Continuous Type, Intermittent Type in the Global Radiofrequency Thawing Equipment Market:

In the Global Radiofrequency Thawing Equipment Market, there are two primary types of equipment: Continuous Type and Intermittent Type. Continuous Type radiofrequency thawing equipment is designed for large-scale operations where a constant flow of frozen products needs to be thawed efficiently. This type of equipment is ideal for high-volume food processing facilities that require a steady and uninterrupted thawing process. The continuous flow of products through the equipment ensures that there is minimal downtime, maximizing productivity and efficiency. The technology used in Continuous Type equipment allows for precise control over the thawing process, ensuring that the food products are thawed evenly and quickly, which is crucial for maintaining quality and safety standards. On the other hand, Intermittent Type radiofrequency thawing equipment is more suited for smaller operations or facilities that do not require a constant flow of products. This type of equipment allows for more flexibility in the thawing process, as it can be adjusted to accommodate varying volumes and types of food products. Intermittent Type equipment is often used in facilities where the demand for thawed products fluctuates or where there is a need for more specialized thawing processes. Both types of equipment offer significant advantages over traditional thawing methods, such as reduced thawing time, improved product quality, and enhanced food safety. The choice between Continuous and Intermittent Type equipment largely depends on the specific needs and scale of the operation. Continuous Type equipment is typically more expensive due to its advanced technology and higher capacity, but it offers greater efficiency and productivity for large-scale operations. Intermittent Type equipment, while generally more affordable, provides the flexibility and adaptability needed for smaller or more specialized operations. As the Global Radiofrequency Thawing Equipment Market continues to evolve, manufacturers are focusing on developing more advanced and user-friendly equipment to meet the diverse needs of food processors. This includes innovations in energy efficiency, automation, and integration with other food processing technologies. The growing emphasis on food safety and quality is also driving the demand for radiofrequency thawing equipment, as it offers a more controlled and hygienic thawing process compared to traditional methods. Overall, the choice between Continuous and Intermittent Type radiofrequency thawing equipment depends on the specific requirements of the operation, including the volume of products to be thawed, the level of automation desired, and the budget available for investment in new technology. As the market continues to grow, it is expected that both types of equipment will see increased adoption across various segments of the food processing industry.

Meat, Poultry, Seafood, Fruits and Vegetables, Others in the Global Radiofrequency Thawing Equipment Market:

The Global Radiofrequency Thawing Equipment Market finds extensive usage across various sectors, including meat, poultry, seafood, fruits and vegetables, and other food products. In the meat industry, radiofrequency thawing equipment is used to quickly and uniformly thaw large cuts of meat, ensuring that the quality and texture of the meat are preserved. This is particularly important for meat processors who need to maintain the freshness and safety of their products while meeting high demand. The rapid thawing process offered by radiofrequency technology helps to minimize the growth of harmful bacteria, making it a preferred choice for meat processors. Similarly, in the poultry industry, radiofrequency thawing equipment is used to efficiently thaw frozen poultry products, such as whole chickens or turkey breasts. The even distribution of heat ensures that the poultry is thawed uniformly, reducing the risk of uneven cooking or spoilage. This technology is especially beneficial for large-scale poultry processors who need to quickly and safely thaw large volumes of products. In the seafood industry, radiofrequency thawing equipment is used to thaw a variety of frozen seafood products, including fish fillets, shrimp, and shellfish. The gentle and controlled thawing process helps to preserve the delicate texture and flavor of seafood, which can be easily compromised by traditional thawing methods. This is crucial for seafood processors who need to maintain the quality and freshness of their products to meet consumer expectations. For fruits and vegetables, radiofrequency thawing equipment offers a fast and efficient way to thaw frozen produce without compromising their nutritional value or texture. This is particularly important for processors who supply frozen fruits and vegetables to the retail and foodservice sectors, where quality and appearance are key factors for consumers. The ability to quickly thaw large volumes of produce also helps to reduce processing time and increase productivity. In addition to these primary sectors, radiofrequency thawing equipment is also used in other areas of the food industry, such as bakery products, dairy, and ready-to-eat meals. The versatility and efficiency of this technology make it an attractive option for food processors looking to improve their thawing processes and maintain high standards of quality and safety. Overall, the Global Radiofrequency Thawing Equipment Market plays a crucial role in the food processing industry, offering a reliable and efficient solution for thawing a wide range of frozen products. As the demand for high-quality, safe, and quickly processed food continues to grow, the adoption of radiofrequency thawing equipment is expected to increase across various sectors.

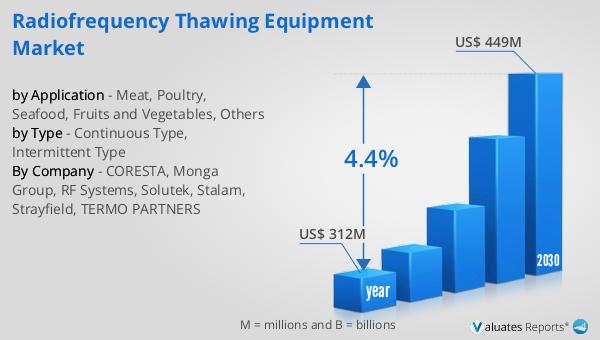

Global Radiofrequency Thawing Equipment Market Outlook:

In 2023, the global market for Radiofrequency Thawing Equipment was valued at approximately $312 million. Looking ahead, this market is anticipated to expand, reaching an estimated size of $449 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 4.4% over the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for efficient and safe food processing technologies, advancements in radiofrequency thawing equipment, and the growing awareness of food safety standards. As food processors seek to enhance their operations and meet the increasing demand for high-quality products, the adoption of radiofrequency thawing equipment is expected to rise. This technology offers significant advantages over traditional thawing methods, such as reduced thawing time, improved product quality, and enhanced food safety. As a result, the Global Radiofrequency Thawing Equipment Market is poised for continued growth, driven by the need for innovative and efficient solutions in the food processing industry. The projected growth in market size reflects the increasing importance of radiofrequency thawing equipment in meeting the evolving needs of food processors worldwide.

| Report Metric | Details |

| Report Name | Radiofrequency Thawing Equipment Market |

| Accounted market size in year | US$ 312 million |

| Forecasted market size in 2030 | US$ 449 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CORESTA, Monga Group, RF Systems, Solutek, Stalam, Strayfield, TERMO PARTNERS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |