What is Global High Pressure Booster Pumps Market?

The Global High Pressure Booster Pumps Market is a dynamic and essential segment of the industrial equipment sector, focusing on pumps designed to increase the pressure of fluids in various applications. These pumps are crucial in industries where high-pressure fluid delivery is necessary, such as water treatment, chemical processing, and oil and gas. High pressure booster pumps are engineered to handle fluids at elevated pressures, ensuring efficient and reliable operation in demanding environments. They are used to enhance the pressure of water, chemicals, and other fluids, making them vital for processes that require precise pressure control. The market for these pumps is driven by the growing demand for efficient fluid handling solutions across different industries, technological advancements in pump design, and the need for energy-efficient systems. As industries continue to expand and modernize, the demand for high pressure booster pumps is expected to rise, making this market a key area of focus for manufacturers and investors alike. The versatility and efficiency of these pumps make them indispensable in various industrial applications, contributing to their steady market growth.

Single Stage, Multiple Stage in the Global High Pressure Booster Pumps Market:

In the realm of high pressure booster pumps, the distinction between single-stage and multiple-stage pumps is significant, as each type serves different operational needs and applications. Single-stage high pressure booster pumps are designed with one impeller, which is responsible for increasing the pressure of the fluid. These pumps are typically used in applications where a moderate increase in pressure is sufficient. They are known for their simplicity, ease of maintenance, and cost-effectiveness, making them a popular choice for smaller-scale operations or where the pressure requirements are not exceedingly high. Single-stage pumps are often employed in residential water systems, small-scale irrigation, and certain industrial processes where the pressure boost needed is minimal. On the other hand, multiple-stage high pressure booster pumps consist of two or more impellers, which work in series to progressively increase the pressure of the fluid. This design allows for a much higher pressure boost compared to single-stage pumps, making them suitable for more demanding applications. Multiple-stage pumps are commonly used in industries such as oil and gas, mining, and large-scale water treatment facilities, where high pressure is crucial for efficient operation. The ability to achieve higher pressures with multiple-stage pumps makes them ideal for transporting fluids over long distances or to elevated locations. Additionally, these pumps are often used in applications where precise pressure control is necessary, such as in chemical processing or in the aerospace industry. The choice between single-stage and multiple-stage pumps depends largely on the specific requirements of the application, including the desired pressure increase, the nature of the fluid being pumped, and the operational environment. While single-stage pumps offer simplicity and cost savings, multiple-stage pumps provide the capability to handle more complex and demanding tasks. As industries continue to evolve and the demand for high-pressure fluid handling solutions grows, both single-stage and multiple-stage high pressure booster pumps will play a crucial role in meeting these needs. Manufacturers are continually innovating to improve the efficiency, reliability, and performance of these pumps, ensuring they can meet the diverse requirements of modern industrial applications.

Water Treatment, Chemical Industry, Aerospace, Mining, Food Processing, Other in the Global High Pressure Booster Pumps Market:

High pressure booster pumps are integral to a variety of industries, each with unique requirements and applications. In water treatment, these pumps are used to increase the pressure of water to ensure efficient filtration and distribution. They play a critical role in processes such as reverse osmosis, where high pressure is necessary to force water through semi-permeable membranes, removing impurities and producing clean water. In the chemical industry, high pressure booster pumps are essential for transporting chemicals through pipelines, ensuring precise pressure control to maintain the integrity of chemical reactions and processes. These pumps are designed to handle corrosive and hazardous fluids, making them indispensable in chemical manufacturing and processing. In the aerospace industry, high pressure booster pumps are used in hydraulic systems to control the movement of aircraft components, such as landing gear and flaps. The ability to deliver high pressure fluid reliably and efficiently is crucial for the safety and performance of aerospace systems. In mining, these pumps are used to transport water and slurry over long distances, often in challenging environments. The high pressure capability of these pumps ensures that fluids can be moved efficiently, supporting mining operations and reducing downtime. In food processing, high pressure booster pumps are used to ensure the hygienic and efficient movement of liquids, such as water, juices, and sauces. They are designed to meet strict sanitary standards, ensuring that food products are processed safely and efficiently. Other industries, such as oil and gas, also rely on high pressure booster pumps for various applications, including the transportation of oil and gas through pipelines and the injection of fluids into wells. The versatility and reliability of high pressure booster pumps make them a critical component in these industries, supporting efficient and safe operations. As the demand for high-pressure fluid handling solutions continues to grow, the role of these pumps in various industries is expected to expand, driving innovation and development in the market.

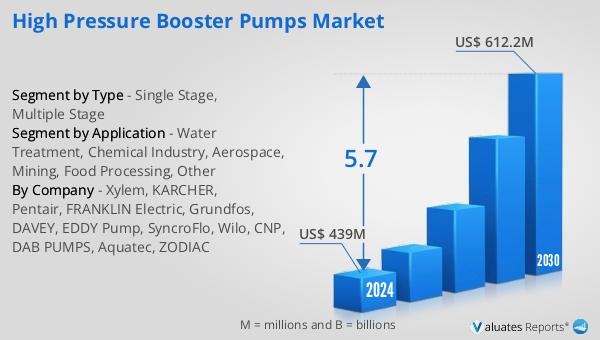

Global High Pressure Booster Pumps Market Outlook:

The outlook for the global High Pressure Booster Pumps market indicates a promising growth trajectory. It is anticipated that the market will expand from a valuation of US$ 439 million in 2024 to reach approximately US$ 612.2 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 5.7% over the forecast period. This upward trend reflects the increasing demand for high-pressure fluid handling solutions across various industries, driven by the need for efficient and reliable systems. The market's growth is supported by technological advancements in pump design, which enhance performance and energy efficiency. Additionally, the expansion of industries such as water treatment, chemical processing, and oil and gas further fuels the demand for high pressure booster pumps. As industries continue to modernize and expand, the need for high-pressure pumps that can handle complex and demanding applications is expected to rise. This growth presents significant opportunities for manufacturers and investors in the high pressure booster pumps market, as they seek to capitalize on the increasing demand for advanced fluid handling solutions. The market's positive outlook underscores the importance of these pumps in supporting industrial operations and meeting the evolving needs of various sectors.

| Report Metric | Details |

| Report Name | High Pressure Booster Pumps Market |

| Accounted market size in 2024 | US$ 439 million |

| Forecasted market size in 2030 | US$ 612.2 million |

| CAGR | 5.7 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Xylem, KARCHER, Pentair, FRANKLIN Electric, Grundfos, DAVEY, EDDY Pump, SyncroFlo, Wilo, CNP, DAB PUMPS, Aquatec, ZODIAC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |