What is Global Pneumatic Knife Gate Valve Market?

The Global Pneumatic Knife Gate Valve Market is a specialized segment within the broader industrial valve industry, focusing on valves that are specifically designed to handle slurry, viscous, and corrosive media. These valves are characterized by their ability to cut through thick fluids and solids, making them ideal for industries that deal with challenging materials. The "pneumatic" aspect refers to the use of compressed air to operate the valve, which allows for quick and efficient opening and closing. This feature is particularly beneficial in automated systems where precision and speed are crucial. The market for these valves is driven by the increasing demand in industries such as wastewater treatment, mining, and pulp and paper, where the handling of abrasive and corrosive materials is common. Additionally, the growing focus on improving operational efficiency and reducing downtime in industrial processes further fuels the demand for pneumatic knife gate valves. As industries continue to expand and modernize, the need for reliable and efficient valve solutions is expected to rise, making the Global Pneumatic Knife Gate Valve Market a critical component of industrial infrastructure.

Stainless Steel, Plastic, Others in the Global Pneumatic Knife Gate Valve Market:

In the Global Pneumatic Knife Gate Valve Market, materials such as stainless steel, plastic, and others play a significant role in determining the valve's performance, durability, and suitability for various applications. Stainless steel is a popular choice due to its excellent resistance to corrosion and high temperatures, making it ideal for harsh environments. It is commonly used in industries like oil and gas, chemical processing, and food and beverage, where the valve's ability to withstand aggressive media and maintain hygiene standards is crucial. Stainless steel valves are known for their longevity and minimal maintenance requirements, which contribute to their widespread adoption in critical applications. On the other hand, plastic valves offer a cost-effective alternative, particularly in applications where the media is not highly abrasive or corrosive. Plastics such as PVC and polypropylene are lightweight, easy to install, and resistant to a wide range of chemicals, making them suitable for industries like water treatment and agriculture. However, they may not be as durable as stainless steel in extreme conditions, which limits their use in certain high-pressure or high-temperature applications. Other materials, such as cast iron and carbon steel, are also used in the production of pneumatic knife gate valves, each offering unique benefits. Cast iron is known for its strength and durability, making it suitable for heavy-duty applications, while carbon steel provides a good balance of strength and cost-effectiveness. The choice of material often depends on the specific requirements of the application, including the type of media, operating conditions, and budget constraints. As the Global Pneumatic Knife Gate Valve Market continues to evolve, manufacturers are exploring new materials and technologies to enhance valve performance and meet the diverse needs of various industries. This ongoing innovation is expected to drive further growth and diversification in the market, offering end-users a wider range of options to choose from.

Pulp and Paper, Wastewater Treatment, Oil and Gas, Mining, Power, Others in the Global Pneumatic Knife Gate Valve Market:

The Global Pneumatic Knife Gate Valve Market finds extensive usage across various industries, each with its unique requirements and challenges. In the pulp and paper industry, these valves are essential for handling the thick, fibrous slurries that are characteristic of the production process. The ability of pneumatic knife gate valves to cut through these dense materials without clogging or causing downtime is crucial for maintaining efficient operations. Similarly, in wastewater treatment, these valves are used to manage the flow of sludge and other solid-laden fluids. Their robust design and reliable performance ensure that treatment plants can operate smoothly, even when dealing with abrasive and corrosive substances. In the oil and gas sector, pneumatic knife gate valves are employed to control the flow of crude oil, natural gas, and other hydrocarbons. The harsh conditions and high pressures typical of this industry require valves that can withstand extreme environments while providing precise control. Mining operations also benefit from the use of these valves, particularly in the processing of minerals and ores. The ability to handle abrasive slurries and resist wear and tear makes pneumatic knife gate valves an indispensable tool in mining applications. In the power industry, these valves are used in various processes, including the handling of ash and other by-products of combustion. Their durability and reliability ensure that power plants can maintain continuous operations without unexpected interruptions. Beyond these industries, pneumatic knife gate valves are also used in sectors such as food and beverage, chemical processing, and pharmaceuticals, where the need for hygienic and efficient flow control is paramount. The versatility and adaptability of these valves make them a valuable asset in any industry that requires the handling of challenging media. As industries continue to evolve and face new challenges, the demand for advanced valve solutions like pneumatic knife gate valves is expected to grow, driving further innovation and development in the market.

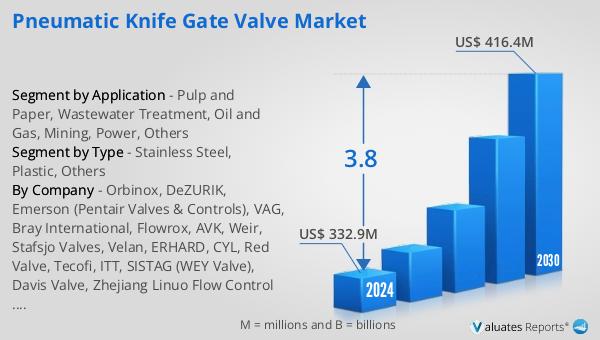

Global Pneumatic Knife Gate Valve Market Outlook:

The outlook for the Global Pneumatic Knife Gate Valve Market indicates a promising growth trajectory over the coming years. The market is anticipated to expand from a valuation of US$ 332.9 million in 2024 to reach approximately US$ 416.4 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 3.8% throughout the forecast period. This steady increase in market size reflects the rising demand for efficient and reliable valve solutions across various industries. The growth can be attributed to several factors, including the ongoing industrialization and modernization efforts in emerging economies, which are driving the need for advanced infrastructure and equipment. Additionally, the increasing focus on sustainability and environmental compliance is encouraging industries to adopt more efficient and durable valve solutions, further boosting the demand for pneumatic knife gate valves. As industries continue to prioritize operational efficiency and cost-effectiveness, the market for these valves is likely to witness sustained growth. The projected expansion of the Global Pneumatic Knife Gate Valve Market underscores the importance of these valves in supporting industrial processes and highlights the opportunities for manufacturers to innovate and meet the evolving needs of their customers.

| Report Metric | Details |

| Report Name | Pneumatic Knife Gate Valve Market |

| Accounted market size in 2024 | US$ 332.9 million |

| Forecasted market size in 2030 | US$ 416.4 million |

| CAGR | 3.8 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Orbinox, DeZURIK, Emerson (Pentair Valves & Controls), VAG, Bray International, Flowrox, AVK, Weir, Stafsjo Valves, Velan, ERHARD, CYL, Red Valve, Tecofi, ITT, SISTAG (WEY Valve), Davis Valve, Zhejiang Linuo Flow Control Technolog, GEFA Processtechnik, Trueline Valve Corporation, SUPERO SEIKI, Chuan Chuan Metal Valves, Tianjin Exxon Valve |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |