What is Global Mining Remanufacturing Components Market?

The Global Mining Remanufacturing Components Market is a specialized sector within the broader mining industry that focuses on the refurbishment and reuse of essential machinery components. This market is driven by the need to reduce costs and environmental impact while maintaining operational efficiency. Remanufacturing involves restoring used components to like-new condition, which can significantly extend the lifespan of mining equipment. This process not only helps in conserving resources but also reduces the carbon footprint associated with manufacturing new parts. The market encompasses a wide range of components, including engines, hydraulic cylinders, axles, transmissions, differentials, torque converters, and final drives. These components are crucial for the functioning of heavy machinery used in mining operations. As the demand for minerals and metals continues to rise globally, the need for efficient and sustainable mining practices becomes more pressing. The remanufacturing of components offers a viable solution by ensuring that mining equipment remains operational without the need for constant replacement. This market is expected to grow steadily as more mining companies recognize the benefits of remanufacturing in terms of cost savings and environmental sustainability.

Engine, Hydraulic Cylinder, Axle, Transmission, Differential, Torque Convertor, Final Drive in the Global Mining Remanufacturing Components Market:

In the Global Mining Remanufacturing Components Market, several key components play a vital role in the efficient operation of mining machinery. The engine is the heart of any mining equipment, providing the necessary power to drive operations. Remanufactured engines are meticulously restored to ensure they deliver optimal performance, reliability, and fuel efficiency, which are crucial for minimizing downtime and operational costs. Hydraulic cylinders are another critical component, responsible for the movement and control of various parts of mining machinery. These cylinders are remanufactured to withstand the harsh conditions of mining environments, ensuring smooth and precise operations. Axles, which support the weight of the machinery and facilitate movement, are also remanufactured to enhance durability and performance. Transmissions, which transfer power from the engine to the wheels or tracks, are refurbished to ensure seamless power delivery and efficient operation. Differentials, which allow wheels to rotate at different speeds, are remanufactured to maintain stability and control, especially in challenging terrains. Torque converters, which transmit and multiply engine torque, are restored to ensure efficient power transfer and smooth acceleration. Finally, the final drive, which is the last component in the powertrain, is remanufactured to provide the necessary torque and speed to the wheels or tracks. Each of these components is essential for the overall performance and longevity of mining equipment. By opting for remanufactured components, mining companies can significantly reduce costs, minimize environmental impact, and ensure the reliability of their operations. The remanufacturing process involves rigorous testing and quality control measures to ensure that each component meets or exceeds original equipment manufacturer (OEM) standards. This attention to detail ensures that remanufactured components deliver the same level of performance and reliability as new parts, making them a cost-effective and sustainable choice for the mining industry.

Metal Minerals, Non-Metallic Minerals in the Global Mining Remanufacturing Components Market:

The Global Mining Remanufacturing Components Market plays a significant role in the extraction and processing of both metal and non-metallic minerals. In the realm of metal minerals, which include commodities like gold, silver, copper, and iron, remanufactured components are essential for maintaining the heavy machinery used in extraction and processing. These metals are often found in challenging environments, requiring robust and reliable equipment to ensure efficient operations. Remanufactured components, such as engines and hydraulic systems, provide the necessary power and precision to extract these valuable resources while minimizing downtime and maintenance costs. The durability and performance of remanufactured parts are crucial in ensuring that mining operations can continue uninterrupted, even in the harshest conditions. In the case of non-metallic minerals, which include materials like limestone, phosphate, and gypsum, the demand for remanufactured components is equally significant. These minerals are often used in construction, agriculture, and various industrial applications, necessitating efficient and reliable extraction processes. Remanufactured components help maintain the machinery used in these operations, ensuring that they operate at peak efficiency. The cost savings associated with remanufactured parts are particularly beneficial in the non-metallic minerals sector, where margins can be tighter. By reducing the need for new components, mining companies can allocate resources more effectively, investing in other areas of their operations. Additionally, the environmental benefits of remanufacturing align with the growing emphasis on sustainable mining practices. By choosing remanufactured components, companies can reduce their carbon footprint and contribute to a more sustainable future. Overall, the Global Mining Remanufacturing Components Market provides essential support to the mining industry, enabling the efficient and sustainable extraction of both metal and non-metallic minerals.

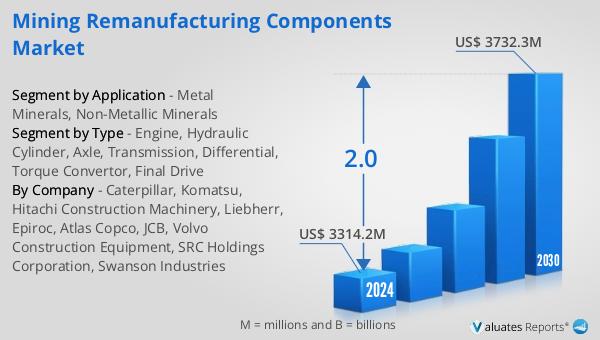

Global Mining Remanufacturing Components Market Outlook:

The outlook for the Global Mining Remanufacturing Components Market indicates a steady growth trajectory over the coming years. According to market analysis, the market is expected to expand from a valuation of approximately US$ 3314.2 million in 2024 to around US$ 3732.3 million by 2030. This growth represents a Compound Annual Growth Rate (CAGR) of 2.0% during the forecast period. This projected growth can be attributed to several factors, including the increasing demand for cost-effective and sustainable mining solutions. As mining companies face rising operational costs and environmental pressures, the adoption of remanufactured components offers a viable solution. These components not only help in reducing costs but also contribute to environmental sustainability by minimizing waste and conserving resources. The market's growth is also supported by advancements in remanufacturing technologies, which enhance the quality and performance of refurbished components. As more companies recognize the benefits of remanufacturing, the demand for these components is expected to rise, driving market growth. The steady CAGR of 2.0% reflects the growing acceptance and adoption of remanufactured components in the mining industry, highlighting their importance in achieving operational efficiency and sustainability.

| Report Metric | Details |

| Report Name | Mining Remanufacturing Components Market |

| Accounted market size in 2024 | US$ 3314.2 million |

| Forecasted market size in 2030 | US$ 3732.3 million |

| CAGR | 2.0 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Caterpillar, Komatsu, Hitachi Construction Machinery, Liebherr, Epiroc, Atlas Copco, JCB, Volvo Construction Equipment, SRC Holdings Corporation, Swanson Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |