What is Global Fluid Loss Additives Market?

The Global Fluid Loss Additives Market is a crucial segment within the oil and gas industry, focusing on materials that help control the loss of fluid during drilling and cementing operations. These additives are essential in maintaining the stability and integrity of the wellbore by preventing the loss of drilling fluids into the formation. Fluid loss can lead to various operational challenges, including increased costs, reduced efficiency, and potential damage to the reservoir. The market for fluid loss additives is driven by the growing demand for energy, which necessitates efficient drilling operations. As exploration activities extend into deeper and more challenging environments, the need for advanced fluid loss control solutions becomes even more critical. The market encompasses a range of products, including synthetically modified natural additives, synthetic polymers, and natural materials, each offering unique benefits and applications. The ongoing advancements in drilling technologies and the increasing focus on sustainable and environmentally friendly solutions are expected to further influence the development and adoption of fluid loss additives in the coming years.

Synthetically Modified Natural (PAC, CMC), Synthetic (Acrylic Sulphonated Polymers), Natural (Starch, Lignin, Bentonite)) in the Global Fluid Loss Additives Market:

In the Global Fluid Loss Additives Market, various types of additives are employed to address the challenges associated with fluid loss during drilling and cementing operations. Synthetically modified natural additives, such as Polyanionic Cellulose (PAC) and Carboxymethyl Cellulose (CMC), are widely used due to their ability to enhance the viscosity and stability of drilling fluids. PAC and CMC are derived from natural cellulose and are chemically modified to improve their performance in high-temperature and high-pressure conditions. These additives are particularly effective in reducing fluid loss by forming a thin, impermeable filter cake on the wellbore walls, thus preventing the invasion of drilling fluids into the formation. Synthetic additives, such as acrylic sulphonated polymers, offer superior performance in extreme conditions. These polymers are designed to withstand high temperatures and salinity levels, making them ideal for use in challenging drilling environments. They provide excellent fluid loss control by creating a robust barrier that minimizes the permeability of the filter cake. Additionally, synthetic polymers are known for their compatibility with various drilling fluid systems, enhancing their versatility and effectiveness. Natural additives, including starch, lignin, and bentonite, are also integral to the fluid loss additives market. Starch, derived from plants, is a biodegradable and cost-effective option for fluid loss control. It swells in the presence of water, forming a gel-like structure that reduces fluid invasion. Lignin, a byproduct of the paper and pulp industry, is another natural additive used for its ability to stabilize drilling fluids and improve filter cake quality. Bentonite, a type of clay, is renowned for its swelling properties and is commonly used to increase the viscosity of drilling fluids, thereby reducing fluid loss. Each of these additives plays a vital role in ensuring the efficiency and safety of drilling operations, and their selection depends on the specific requirements of the drilling environment. The continuous research and development efforts in this field aim to enhance the performance of these additives while minimizing their environmental impact, reflecting the industry's commitment to sustainable practices.

Drilling Fluid, Cement Slurry in the Global Fluid Loss Additives Market:

The usage of Global Fluid Loss Additives Market in drilling fluid and cement slurry applications is pivotal for the success of drilling operations. In drilling fluids, fluid loss additives are essential for maintaining wellbore stability and preventing the invasion of drilling fluids into the formation. This is particularly important in porous and permeable formations where fluid loss can lead to severe operational challenges, including wellbore instability, formation damage, and increased drilling costs. Fluid loss additives work by forming a thin, impermeable filter cake on the wellbore walls, which acts as a barrier to fluid invasion. This not only helps in maintaining the integrity of the wellbore but also enhances the efficiency of the drilling process by reducing non-productive time. In cement slurry applications, fluid loss additives are crucial for ensuring the proper placement and setting of cement in the wellbore. During cementing operations, the loss of fluid from the cement slurry can lead to incomplete cementing, resulting in poor zonal isolation and potential well integrity issues. Fluid loss additives in cement slurries help in controlling the rate of fluid loss, ensuring that the cement remains in place and sets properly. This is vital for achieving a strong bond between the casing and the formation, which is essential for the long-term stability and safety of the well. The selection of appropriate fluid loss additives for drilling fluids and cement slurries depends on various factors, including the formation characteristics, temperature, pressure, and the specific requirements of the drilling operation. The ongoing advancements in fluid loss additive technologies are focused on improving their performance in challenging environments, such as deepwater and high-temperature wells, while also addressing environmental concerns. The development of biodegradable and environmentally friendly additives is a key area of focus, reflecting the industry's commitment to sustainable and responsible drilling practices.

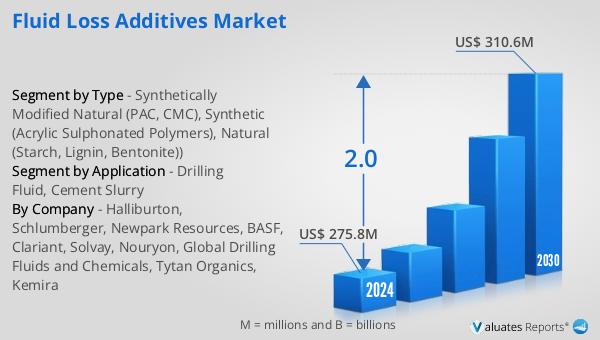

Global Fluid Loss Additives Market Outlook:

The outlook for the Global Fluid Loss Additives Market indicates a steady growth trajectory over the coming years. The market is anticipated to expand from a valuation of US$ 275.8 million in 2024 to approximately US$ 310.6 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 2.0% during the forecast period. This projected increase is driven by several factors, including the rising demand for energy, advancements in drilling technologies, and the need for efficient fluid loss control solutions in increasingly challenging drilling environments. As exploration activities extend into deeper and more complex formations, the demand for high-performance fluid loss additives is expected to rise. Additionally, the industry's focus on sustainable and environmentally friendly solutions is likely to influence the development and adoption of new fluid loss additive technologies. The market's growth is also supported by the continuous research and development efforts aimed at enhancing the performance and environmental profile of fluid loss additives. These efforts are expected to result in the introduction of innovative products that meet the evolving needs of the oil and gas industry. Overall, the Global Fluid Loss Additives Market is poised for steady growth, driven by the increasing complexity of drilling operations and the industry's commitment to sustainable practices.

| Report Metric | Details |

| Report Name | Fluid Loss Additives Market |

| Accounted market size in 2024 | US$ 275.8 million |

| Forecasted market size in 2030 | US$ 310.6 million |

| CAGR | 2.0 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Halliburton, Schlumberger, Newpark Resources, BASF, Clariant, Solvay, Nouryon, Global Drilling Fluids and Chemicals, Tytan Organics, Kemira |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |