What is Global Industrial Couplings Market?

The Global Industrial Couplings Market refers to the worldwide industry involved in the production and distribution of couplings used in various industrial applications. Couplings are mechanical devices that connect two shafts together to transmit power and accommodate misalignment between them. They are essential components in machinery and equipment across numerous sectors, including manufacturing, energy, mining, and transportation. The market for industrial couplings is driven by the need for efficient power transmission and the growing demand for machinery and equipment in developing economies. Technological advancements and the increasing focus on energy efficiency and sustainability are also contributing to the market's growth. Companies in this market are continuously innovating to develop couplings that offer better performance, durability, and ease of maintenance. The market is characterized by a wide range of products, including flexible and rigid couplings, each designed to meet specific industrial requirements. As industries continue to expand and modernize, the demand for reliable and efficient coupling solutions is expected to rise, making the Global Industrial Couplings Market a vital component of the industrial supply chain.

Flexible Couplings, Rigid Couplings in the Global Industrial Couplings Market:

Flexible couplings and rigid couplings are two primary types of couplings used in the Global Industrial Couplings Market, each serving distinct purposes based on their design and application. Flexible couplings are designed to accommodate misalignment between connected shafts, absorb shock loads, and reduce vibration. They are typically used in applications where there is a need for some degree of flexibility to compensate for minor misalignments or to protect the connected equipment from excessive stress. Flexible couplings can be made from various materials, including rubber, elastomers, and metals, and come in different designs such as jaw couplings, gear couplings, and disc couplings. These couplings are particularly useful in applications where precision alignment is challenging or where the equipment is subject to dynamic loads and vibrations. On the other hand, rigid couplings are used in applications where precise alignment between shafts is required, and there is no need for flexibility. They provide a solid connection between shafts, ensuring that they rotate in unison without any relative motion. Rigid couplings are typically used in applications where high torque transmission is necessary, and any misalignment could lead to equipment failure or reduced efficiency. They are often made from metals such as steel or aluminum and are available in various designs, including sleeve couplings, flange couplings, and clamp couplings. While rigid couplings offer high strength and reliability, they require precise alignment during installation to prevent excessive wear and tear on the connected equipment. In the Global Industrial Couplings Market, the choice between flexible and rigid couplings depends on the specific requirements of the application, including factors such as the level of misalignment, torque transmission needs, and environmental conditions. Both types of couplings play a crucial role in ensuring the efficient operation of machinery and equipment across various industries.

Energy, Metals, Mining, Oil and Gas, Food Processing, Others in the Global Industrial Couplings Market:

The Global Industrial Couplings Market finds extensive usage across several key industries, including energy, metals, mining, oil and gas, food processing, and others. In the energy sector, industrial couplings are essential components in power generation equipment, including turbines, generators, and pumps. They help in transmitting power efficiently and accommodating misalignments that may occur due to thermal expansion or other factors. In the metals industry, couplings are used in machinery involved in metal processing, such as rolling mills and furnaces, where they help in maintaining precise alignment and reducing vibrations. The mining industry relies on industrial couplings for equipment such as conveyors, crushers, and grinding mills, where they play a critical role in ensuring reliable power transmission and accommodating the harsh operating conditions. In the oil and gas sector, couplings are used in drilling rigs, pumps, and compressors, where they help in transmitting power and accommodating misalignments caused by the dynamic nature of the operations. The food processing industry uses industrial couplings in equipment such as mixers, conveyors, and packaging machines, where they help in maintaining hygiene standards and ensuring efficient operation. Other industries that utilize industrial couplings include transportation, construction, and manufacturing, where they are used in various machinery and equipment to ensure efficient power transmission and accommodate misalignments. The versatility and reliability of industrial couplings make them indispensable components in these industries, contributing to the overall efficiency and productivity of the operations.

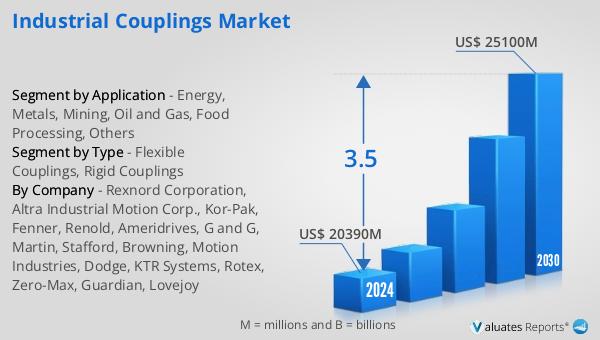

Global Industrial Couplings Market Outlook:

The outlook for the Global Industrial Couplings Market indicates a steady growth trajectory over the coming years. The market is expected to expand from a valuation of approximately US$ 20,390 million in 2024 to around US$ 25,100 million by 2030. This growth is projected to occur at a Compound Annual Growth Rate (CAGR) of 3.5% during the forecast period. This anticipated growth can be attributed to several factors, including the increasing demand for industrial machinery and equipment in developing economies, the ongoing modernization of industrial infrastructure, and the rising focus on energy efficiency and sustainability. As industries continue to expand and evolve, the need for reliable and efficient coupling solutions is expected to rise, driving the growth of the market. Additionally, technological advancements in coupling design and materials are likely to contribute to the market's expansion by offering improved performance, durability, and ease of maintenance. Companies operating in the Global Industrial Couplings Market are expected to focus on innovation and product development to meet the evolving needs of their customers and maintain a competitive edge in the market. Overall, the Global Industrial Couplings Market is poised for steady growth, driven by the increasing demand for efficient power transmission solutions across various industries.

| Report Metric | Details |

| Report Name | Industrial Couplings Market |

| Accounted market size in 2024 | US$ 20390 million |

| Forecasted market size in 2030 | US$ 25100 million |

| CAGR | 3.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Rexnord Corporation, Altra Industrial Motion Corp., Kor-Pak, Fenner, Renold, Ameridrives, G and G, Martin, Stafford, Browning, Motion Industries, Dodge, KTR Systems, Rotex, Zero-Max, Guardian, Lovejoy |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |