What is Global Gripper Assembly Market?

The Global Gripper Assembly Market refers to the industry focused on the production and distribution of gripper assemblies, which are essential components in automation and robotics. These assemblies are designed to handle, manipulate, and secure objects in various industrial applications. Grippers are crucial in manufacturing processes where precision and efficiency are paramount. They come in different types, such as pneumatic, hydraulic, and electric, each suited for specific tasks and environments. The market is driven by the increasing adoption of automation across industries to enhance productivity and reduce labor costs. As industries strive for higher efficiency and precision, the demand for advanced gripper technologies continues to rise. This market encompasses a wide range of industries, including automotive, electronics, pharmaceuticals, and more, each requiring tailored gripper solutions to meet their unique operational needs. The growth of this market is also fueled by technological advancements, such as the integration of sensors and artificial intelligence, which enhance the functionality and adaptability of gripper assemblies. As a result, the Global Gripper Assembly Market is poised for significant growth, driven by the ongoing trend towards automation and the need for innovative solutions in industrial processes.

Lightweight Aluminium, Carbon Fibre Plate, Others in the Global Gripper Assembly Market:

In the Global Gripper Assembly Market, materials like lightweight aluminum, carbon fiber plates, and others play a pivotal role in the design and functionality of grippers. Lightweight aluminum is a popular choice due to its excellent strength-to-weight ratio, corrosion resistance, and ease of machining. These properties make aluminum an ideal material for grippers that require both durability and agility. Aluminum grippers are often used in applications where speed and precision are critical, such as in the electronics and automotive industries. The lightweight nature of aluminum reduces the overall weight of the robotic arm, allowing for faster and more efficient movements. Additionally, aluminum's resistance to corrosion ensures longevity and reliability in various industrial environments. On the other hand, carbon fiber plates are gaining traction in the gripper assembly market due to their exceptional strength and lightweight characteristics. Carbon fiber is known for its high tensile strength, making it suitable for applications that demand high load-bearing capacity without adding significant weight. This material is particularly advantageous in industries where minimizing weight is crucial, such as aerospace and high-speed manufacturing. Carbon fiber grippers offer enhanced performance by reducing inertia, allowing for quicker response times and improved energy efficiency. Moreover, carbon fiber's resistance to temperature fluctuations and chemical exposure makes it a reliable choice for demanding environments. Beyond aluminum and carbon fiber, other materials are also utilized in the gripper assembly market to cater to specific industry needs. For instance, stainless steel is often used in applications requiring high corrosion resistance and robustness, such as in the food and pharmaceutical industries. Stainless steel grippers are designed to withstand harsh cleaning processes and maintain hygiene standards. Additionally, engineering plastics like polycarbonate and nylon are employed in gripper assemblies for their lightweight and cost-effective properties. These materials are suitable for applications where moderate strength and flexibility are required. The choice of material in gripper assembly design is influenced by factors such as the application's specific requirements, environmental conditions, and cost considerations. Manufacturers in the Global Gripper Assembly Market continuously explore innovative materials and technologies to enhance the performance and versatility of grippers. As industries evolve and demand more sophisticated automation solutions, the development of advanced materials will play a crucial role in shaping the future of gripper assemblies. The integration of smart materials, such as shape-memory alloys and piezoelectric materials, is also being explored to enable adaptive and responsive gripper systems. These materials have the potential to revolutionize the gripper assembly market by providing new functionalities and capabilities. In conclusion, the choice of materials in the Global Gripper Assembly Market is a critical factor that influences the performance, efficiency, and adaptability of grippers. Lightweight aluminum, carbon fiber plates, and other materials each offer unique advantages that cater to the diverse needs of various industries. As technology advances and industries continue to embrace automation, the demand for innovative materials and gripper solutions will drive the growth and evolution of this dynamic market.

Electronics Industries, Semi-conductor Industries, Pharmaceutical Industries, Automobile Industries, Plastic Industries, Precision Engineering Industries in the Global Gripper Assembly Market:

The Global Gripper Assembly Market finds extensive usage across various industries, each leveraging the unique capabilities of grippers to enhance their manufacturing processes. In the electronics industry, grippers are essential for handling delicate components with precision and care. The assembly of electronic devices requires the manipulation of small and sensitive parts, and grippers provide the necessary dexterity and accuracy. They are used in tasks such as pick-and-place operations, circuit board assembly, and component testing. The ability to handle components without causing damage is crucial in maintaining product quality and reducing waste. In the semiconductor industry, grippers play a vital role in wafer handling and processing. The manufacturing of semiconductors involves intricate processes that demand high precision and cleanliness. Grippers are used to transport wafers between different stages of production, ensuring minimal contamination and damage. The use of grippers in semiconductor manufacturing enhances efficiency and reduces the risk of defects, contributing to higher yields and improved product reliability. The pharmaceutical industry also benefits from the capabilities of grippers, particularly in the automation of packaging and handling processes. Grippers are used to handle vials, syringes, and other pharmaceutical products with precision and care. The automation of these processes ensures consistency, reduces the risk of contamination, and enhances overall productivity. In the automobile industry, grippers are employed in various assembly and manufacturing tasks. They are used to handle components such as engine parts, body panels, and interior fittings. The use of grippers in automotive manufacturing improves efficiency, reduces labor costs, and enhances product quality. Grippers enable precise and repeatable movements, ensuring that components are assembled accurately and consistently. In the plastic industry, grippers are used in injection molding and material handling processes. They are employed to handle plastic parts and components, ensuring efficient and accurate placement. Grippers contribute to the automation of plastic manufacturing, reducing cycle times and improving overall productivity. In precision engineering industries, grippers are used in tasks that require high accuracy and repeatability. They are employed in the assembly of precision instruments, medical devices, and other high-tech products. The use of grippers in precision engineering enhances the quality and reliability of products, ensuring that they meet stringent industry standards. Overall, the Global Gripper Assembly Market plays a crucial role in enhancing the efficiency, precision, and productivity of various industries. The versatility and adaptability of grippers make them indispensable tools in modern manufacturing processes. As industries continue to embrace automation and seek innovative solutions, the demand for advanced gripper technologies is expected to grow, driving the evolution of the Global Gripper Assembly Market.

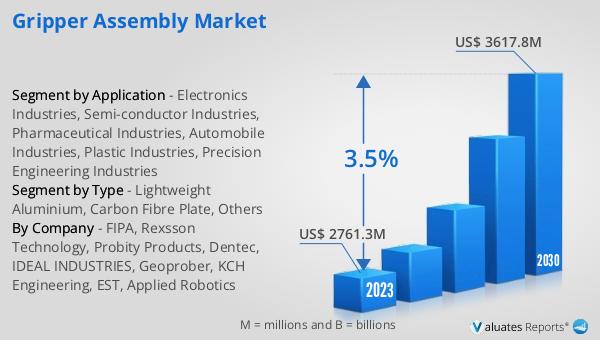

Global Gripper Assembly Market Outlook:

The outlook for the Global Gripper Assembly Market indicates a promising growth trajectory over the coming years. The market is anticipated to expand from a valuation of approximately $2,943.1 million in 2024 to around $3,617.8 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 3.5% during the forecast period. This upward trend reflects the increasing demand for automation solutions across various industries, driven by the need for enhanced efficiency, precision, and cost-effectiveness. As industries continue to adopt automation technologies to streamline their operations, the demand for gripper assemblies is likely to rise. The integration of advanced technologies, such as artificial intelligence and machine learning, into gripper systems is expected to further boost market growth by enabling more sophisticated and adaptable solutions. Additionally, the growing emphasis on sustainability and energy efficiency is likely to drive the development of innovative gripper technologies that minimize energy consumption and reduce environmental impact. As a result, the Global Gripper Assembly Market is poised for significant growth, offering numerous opportunities for manufacturers and stakeholders to capitalize on the increasing demand for automation solutions in various industrial sectors.

| Report Metric | Details |

| Report Name | Gripper Assembly Market |

| Accounted market size in 2024 | US$ 2943.1 million |

| Forecasted market size in 2030 | US$ 3617.8 million |

| CAGR | 3.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | FIPA, Rexsson Technology, Probity Products, Dentec, IDEAL INDUSTRIES, Geoprober, KCH Engineering, EST, Applied Robotics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |