What is Global Extreme Ultraviolet Lithography (EUVL) Systems Market?

Global Extreme Ultraviolet Lithography (EUVL) Systems Market refers to the industry focused on the development and deployment of advanced lithography technology used in semiconductor manufacturing. EUVL is a cutting-edge technology that utilizes extreme ultraviolet (EUV) light to create incredibly small and precise patterns on silicon wafers, which are essential for producing modern microchips. This technology is crucial for the production of smaller, faster, and more efficient electronic devices, as it allows for the creation of circuits with features as small as 7 nanometers or less. The market for EUVL systems is driven by the increasing demand for high-performance computing, smartphones, and other electronic devices that require advanced semiconductor technology. As the semiconductor industry continues to push the boundaries of miniaturization and performance, the EUVL systems market is expected to grow, driven by the need for more sophisticated and efficient manufacturing processes. This growth is further supported by the ongoing research and development efforts aimed at improving the efficiency and cost-effectiveness of EUVL technology, making it a critical component of the future of semiconductor manufacturing.

Laser Produced Plasmas, Vacuum Sparks, Gas Discharges in the Global Extreme Ultraviolet Lithography (EUVL) Systems Market:

Laser Produced Plasmas (LPP), Vacuum Sparks, and Gas Discharges are three key technologies used in the generation of extreme ultraviolet (EUV) light for lithography systems. Each of these technologies plays a crucial role in the EUVL systems market, offering unique advantages and challenges. Laser Produced Plasmas (LPP) is a widely used method for generating EUV light. It involves focusing a high-energy laser onto a target material, typically tin, to create a plasma that emits EUV radiation. The process begins with a laser pulse striking the tin droplet, which vaporizes and forms a plasma. This plasma emits EUV light, which is then collected and directed onto the silicon wafer to create the desired patterns. LPP is favored for its ability to produce high-intensity EUV light, which is essential for achieving the high resolution required in advanced semiconductor manufacturing. However, the process is complex and requires precise control of the laser and target material to ensure consistent EUV output. Vacuum Sparks, on the other hand, utilize electrical discharges in a vacuum to generate EUV light. This method involves creating a high-voltage spark between two electrodes in a vacuum chamber, which ionizes the gas and produces a plasma that emits EUV radiation. Vacuum Sparks are known for their simplicity and cost-effectiveness, as they do not require the high-energy lasers used in LPP. However, they typically produce lower intensity EUV light, which can limit their application in high-resolution lithography. Gas Discharges involve the use of a gas, such as xenon or krypton, which is ionized by an electrical discharge to produce EUV light. This method is similar to Vacuum Sparks but uses a gas instead of a vacuum. Gas Discharges offer the advantage of being able to produce EUV light at different wavelengths, which can be useful for specific lithography applications. However, like Vacuum Sparks, they generally produce lower intensity EUV light compared to LPP. Each of these technologies has its own set of challenges and advantages, and the choice of technology depends on the specific requirements of the lithography process. In the Global Extreme Ultraviolet Lithography (EUVL) Systems Market, the development and optimization of these technologies are critical for improving the efficiency and effectiveness of EUV lithography. As the demand for smaller and more powerful electronic devices continues to grow, the need for advanced EUV light sources will become increasingly important, driving further innovation and development in this field.

Memory, Foundry, Others in the Global Extreme Ultraviolet Lithography (EUVL) Systems Market:

The usage of Global Extreme Ultraviolet Lithography (EUVL) Systems Market in areas such as Memory, Foundry, and Others is pivotal in advancing semiconductor technology. In the Memory sector, EUVL systems are employed to produce memory chips with higher density and performance. Memory chips, such as DRAM and NAND flash, are essential components in a wide range of electronic devices, from smartphones to data centers. The ability to create smaller and more efficient memory chips is crucial for meeting the growing demand for data storage and processing power. EUVL technology enables the production of memory chips with smaller feature sizes, which translates to higher storage capacity and faster data access speeds. This is particularly important as the demand for high-performance computing and data-intensive applications continues to rise. In the Foundry sector, EUVL systems are used to manufacture a variety of semiconductor devices for different industries. Foundries are specialized facilities that produce chips for other companies, and they play a critical role in the semiconductor supply chain. EUVL technology allows foundries to produce chips with advanced features and improved performance, which is essential for meeting the diverse needs of their customers. The ability to produce chips with smaller feature sizes and higher performance is a key competitive advantage for foundries, as it enables them to offer cutting-edge solutions to their clients. In addition to Memory and Foundry, EUVL systems are also used in other areas, such as logic devices and integrated circuits. Logic devices are the building blocks of digital circuits, and they are used in a wide range of applications, from consumer electronics to industrial automation. EUVL technology enables the production of logic devices with smaller feature sizes and higher performance, which is essential for meeting the demands of modern electronic devices. Integrated circuits, which combine multiple electronic components into a single chip, also benefit from EUVL technology. The ability to produce integrated circuits with smaller feature sizes and higher performance is crucial for advancing the capabilities of electronic devices and systems. Overall, the usage of EUVL systems in these areas is critical for driving innovation and progress in the semiconductor industry. As the demand for smaller, faster, and more efficient electronic devices continues to grow, the role of EUVL technology in enabling these advancements will become increasingly important.

Global Extreme Ultraviolet Lithography (EUVL) Systems Market Outlook:

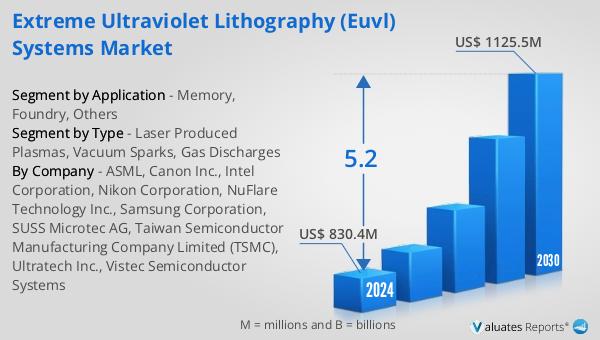

The global market for Extreme Ultraviolet Lithography (EUVL) Systems is anticipated to experience significant growth over the coming years. Starting from a valuation of approximately US$ 830.4 million in 2024, it is expected to reach around US$ 1125.5 million by 2030. This growth trajectory represents a Compound Annual Growth Rate (CAGR) of 5.2% during the forecast period. This projected growth is indicative of the increasing demand for advanced semiconductor manufacturing technologies, driven by the need for smaller, faster, and more efficient electronic devices. The EUVL systems market is poised to benefit from the ongoing advancements in semiconductor technology, as manufacturers seek to push the boundaries of miniaturization and performance. The adoption of EUVL technology is expected to accelerate as it becomes more cost-effective and efficient, enabling the production of next-generation microchips with smaller feature sizes and higher performance. This growth is further supported by the increasing demand for high-performance computing, smartphones, and other electronic devices that rely on advanced semiconductor technology. As the semiconductor industry continues to evolve, the EUVL systems market is set to play a crucial role in shaping the future of electronic device manufacturing.

| Report Metric | Details |

| Report Name | Extreme Ultraviolet Lithography (EUVL) Systems Market |

| Accounted market size in 2024 | US$ 830.4 million |

| Forecasted market size in 2030 | US$ 1125.5 million |

| CAGR | 5.2 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | ASML, Canon Inc., Intel Corporation, Nikon Corporation, NuFlare Technology Inc., Samsung Corporation, SUSS Microtec AG, Taiwan Semiconductor Manufacturing Company Limited (TSMC), Ultratech Inc., Vistec Semiconductor Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |