What is Global Boil-in-Bag Market?

The global boil-in-bag market is a segment of the packaging industry that focuses on providing convenient cooking solutions for consumers. These bags are designed to withstand high temperatures, allowing food to be cooked directly in the bag by boiling. This method is particularly popular for its ease of use, as it eliminates the need for additional pots or pans, reducing cleanup time. The market for boil-in-bag products has been expanding due to increasing consumer demand for quick and easy meal solutions, especially among busy individuals and families. The convenience factor, combined with the ability to preserve the flavor and nutrients of the food, makes boil-in-bag products an attractive option for many. Additionally, the rise in single-person households and the growing trend of on-the-go lifestyles have further fueled the demand for such products. As a result, manufacturers are continuously innovating to improve the quality and functionality of boil-in-bag packaging, ensuring that it meets the evolving needs of consumers. The market is also influenced by environmental concerns, prompting companies to explore sustainable materials and eco-friendly production processes. Overall, the global boil-in-bag market is poised for growth as it adapts to changing consumer preferences and technological advancements.

Plastic, Aluminum Foil, Others in the Global Boil-in-Bag Market:

The global boil-in-bag market is characterized by the use of various materials, each offering distinct advantages and challenges. Plastic is one of the most commonly used materials in boil-in-bag packaging due to its flexibility, durability, and cost-effectiveness. Plastic bags are lightweight and can be easily molded into different shapes and sizes, making them suitable for a wide range of food products. They are also resistant to moisture and can withstand high temperatures, which is essential for the boiling process. However, the environmental impact of plastic has been a growing concern, leading to increased scrutiny and demand for more sustainable alternatives. Manufacturers are exploring biodegradable and recyclable plastic options to address these concerns while maintaining the functional benefits of plastic packaging. Aluminum foil is another material used in the boil-in-bag market, known for its excellent heat conductivity and barrier properties. Aluminum foil bags are particularly effective in preserving the flavor and aroma of the food, as they provide a strong barrier against light, oxygen, and moisture. This makes them ideal for packaging products that require extended shelf life or are sensitive to environmental factors. Additionally, aluminum foil is recyclable, which aligns with the growing consumer preference for environmentally friendly packaging solutions. However, the cost of aluminum foil can be higher compared to plastic, which may impact its widespread adoption in the market. Manufacturers are working to optimize production processes and explore cost-effective solutions to make aluminum foil a more viable option for boil-in-bag packaging. Apart from plastic and aluminum foil, other materials are also being explored in the boil-in-bag market to meet diverse consumer needs and environmental standards. These include materials like paper-based composites and biodegradable films, which offer a more sustainable alternative to traditional packaging materials. Paper-based composites are gaining traction due to their renewable nature and ability to be recycled or composted. They provide a natural look and feel, appealing to eco-conscious consumers who prioritize sustainability. However, the challenge lies in ensuring that these materials can withstand the boiling process without compromising the integrity of the packaging or the safety of the food. Manufacturers are investing in research and development to enhance the performance of these alternative materials, ensuring they meet the necessary standards for boil-in-bag applications. Biodegradable films are another promising option in the boil-in-bag market, offering a solution to the plastic waste problem. These films are designed to break down naturally over time, reducing the environmental impact of packaging waste. They are typically made from renewable resources such as plant-based polymers, which can be composted or recycled. The use of biodegradable films in boil-in-bag packaging is still in its early stages, with ongoing research focused on improving their heat resistance and durability. As technology advances, it is expected that biodegradable films will become more prevalent in the market, providing a sustainable alternative to traditional plastic and aluminum foil packaging. In conclusion, the global boil-in-bag market is evolving with the introduction of various materials that cater to consumer demands for convenience, functionality, and sustainability. While plastic remains a dominant material due to its versatility and cost-effectiveness, the environmental concerns associated with its use have prompted the exploration of alternative materials such as aluminum foil, paper-based composites, and biodegradable films. Each material offers unique benefits and challenges, and manufacturers are continuously innovating to enhance their performance and align with consumer preferences. As the market continues to grow, the focus on sustainable packaging solutions is expected to drive further advancements in material technology, ensuring that boil-in-bag products meet the needs of both consumers and the environment.

Frozen Foods, Ready to Eat Meals, Others in the Global Boil-in-Bag Market:

The global boil-in-bag market finds significant usage in various areas, including frozen foods, ready-to-eat meals, and other food categories. In the frozen foods sector, boil-in-bag packaging is particularly advantageous due to its ability to preserve the quality and freshness of the food during storage and transportation. The bags provide a protective barrier against moisture and air, preventing freezer burn and maintaining the taste and texture of the food. Consumers appreciate the convenience of being able to cook frozen foods directly in the bag, eliminating the need for thawing and reducing preparation time. This makes boil-in-bag packaging an ideal choice for frozen vegetables, seafood, and pre-cooked meals, catering to the growing demand for quick and easy meal solutions. Ready-to-eat meals are another significant application of boil-in-bag packaging, offering consumers a hassle-free dining experience. These meals are pre-cooked and packaged in boil-in-bag containers, allowing consumers to heat them quickly by boiling the bag in water. This method ensures that the meal is evenly heated and retains its flavor and nutritional value. The convenience of ready-to-eat meals in boil-in-bag packaging appeals to busy individuals and families who seek time-saving meal options without compromising on taste or quality. Additionally, the packaging is often designed to be microwave-safe, providing further flexibility for consumers who prefer microwave heating. The versatility and convenience of boil-in-bag packaging make it a popular choice for a wide range of ready-to-eat meals, from pasta dishes to curries and stews. Beyond frozen foods and ready-to-eat meals, boil-in-bag packaging is also used in other food categories, such as grains, sauces, and soups. For grains like rice and quinoa, boil-in-bag packaging offers a convenient cooking solution, allowing consumers to cook the grains directly in the bag without the need for measuring or additional cookware. This simplifies the cooking process and ensures perfectly cooked grains every time. Similarly, sauces and soups packaged in boil-in-bag containers can be easily heated and served, providing a quick and convenient meal option for consumers. The packaging helps to preserve the flavor and aroma of the sauces and soups, ensuring a satisfying dining experience. In addition to its convenience, boil-in-bag packaging also offers benefits in terms of portion control and waste reduction. The packaging is often designed to hold single or multiple servings, allowing consumers to prepare only the amount they need, reducing food waste. This is particularly appealing to single-person households or individuals who prefer portion-controlled meals. Furthermore, the packaging is typically lightweight and compact, making it easy to store and transport. This is advantageous for both consumers and retailers, as it reduces storage space requirements and transportation costs. Overall, the usage of boil-in-bag packaging in frozen foods, ready-to-eat meals, and other food categories highlights its versatility and convenience. The packaging provides a practical solution for consumers seeking quick and easy meal options, while also addressing concerns related to food preservation, portion control, and waste reduction. As consumer lifestyles continue to evolve, the demand for convenient and efficient meal solutions is expected to drive further growth and innovation in the global boil-in-bag market.

Global Boil-in-Bag Market Outlook:

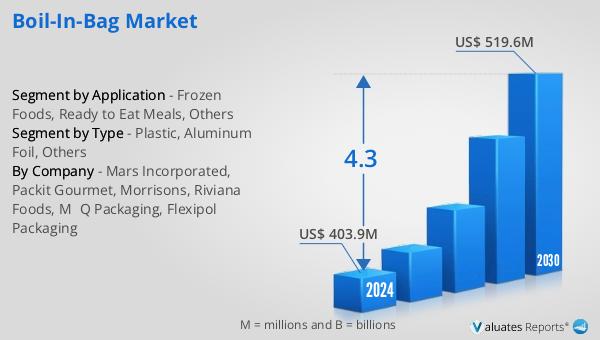

The global boil-in-bag market is anticipated to experience significant growth over the coming years. Starting from a valuation of approximately $403.9 million in 2024, the market is expected to reach around $519.6 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% during the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for convenient and time-saving meal solutions among consumers. As lifestyles become increasingly fast-paced, more individuals and families are seeking quick and easy cooking options that do not compromise on taste or nutritional value. Boil-in-bag products offer a practical solution, allowing consumers to prepare meals with minimal effort and cleanup. Moreover, the market growth is supported by ongoing innovations in packaging materials and technology. Manufacturers are continuously exploring new materials and production processes to enhance the functionality and sustainability of boil-in-bag packaging. This includes the development of eco-friendly materials that address environmental concerns while maintaining the convenience and performance of traditional packaging. As consumer awareness of environmental issues grows, the demand for sustainable packaging solutions is expected to drive further advancements in the market. Additionally, the expansion of the boil-in-bag market is influenced by the increasing popularity of ready-to-eat meals and frozen foods. These segments benefit significantly from boil-in-bag packaging, which offers a convenient and efficient way to prepare and enjoy meals. The ability to cook food directly in the bag without the need for additional cookware appeals to busy consumers who prioritize convenience and efficiency. As a result, the market is likely to see continued growth as more consumers embrace boil-in-bag products as part of their daily meal routines. In conclusion, the global boil-in-bag market is poised for growth, driven by consumer demand for convenient meal solutions, innovations in packaging technology, and the increasing popularity of ready-to-eat meals and frozen foods. The projected growth rate of 4.3% CAGR reflects the market's potential to expand and adapt to changing consumer preferences and environmental considerations. As the market evolves, manufacturers will continue to focus on developing innovative and sustainable packaging solutions to meet the needs of consumers and contribute to the overall growth of the industry.

| Report Metric | Details |

| Report Name | Boil-in-Bag Market |

| Accounted market size in 2024 | US$ 403.9 million |

| Forecasted market size in 2030 | US$ 519.6 million |

| CAGR | 4.3 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Segment by Region |

|

| By Company | Mars Incorporated, Packit Gourmet, Morrisons, Riviana Foods, M&Q Packaging, Flexipol Packaging |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |