What is Food Grade PE Film - Global Market?

Food Grade PE Film is a specialized type of polyethylene film that is designed to meet the stringent safety and quality standards required for food packaging. This film is used globally due to its excellent properties such as flexibility, durability, and resistance to moisture, which make it ideal for preserving the freshness and quality of food products. The global market for Food Grade PE Film is vast and continually expanding, driven by the increasing demand for safe and reliable food packaging solutions. As consumers become more health-conscious and aware of food safety, the need for packaging materials that can protect food from contamination and extend its shelf life has grown significantly. Food Grade PE Film is also favored for its recyclability, aligning with the global push towards sustainable packaging solutions. This market encompasses a wide range of applications, from wrapping fresh produce to packaging processed foods, and is characterized by continuous innovation to improve the film's performance and environmental impact. The market's growth is supported by advancements in manufacturing technologies and the development of new formulations that enhance the film's protective qualities while maintaining its food safety credentials.

Low Density PE, Medium Density PE, High Density PE in the Food Grade PE Film - Global Market:

Low Density Polyethylene (LDPE), Medium Density Polyethylene (MDPE), and High Density Polyethylene (HDPE) are three types of polyethylene used in the production of Food Grade PE Film, each offering distinct properties that cater to different packaging needs. LDPE is known for its high flexibility and transparency, making it ideal for applications where clarity and ease of handling are important. It is commonly used in the packaging of fresh produce, bakery products, and other items where visibility of the product is a key selling point. LDPE's excellent moisture barrier properties help in maintaining the freshness of the food, while its softness and flexibility make it easy to wrap around products of various shapes and sizes. On the other hand, MDPE offers a balance between flexibility and strength, providing a more robust option for packaging applications that require a bit more durability. It is often used in the packaging of frozen foods and other products that need to withstand rough handling during transportation and storage. MDPE's resistance to impact and puncture makes it a reliable choice for protecting food products from physical damage. HDPE, with its high strength and rigidity, is used in applications where maximum protection is required. It is commonly used for packaging bulk food items, such as grains and cereals, as well as for creating sturdy containers and bottles for liquids. HDPE's excellent chemical resistance ensures that it does not react with the food products it comes into contact with, maintaining the integrity and safety of the packaged food. The choice between LDPE, MDPE, and HDPE depends on the specific requirements of the packaging application, including the type of food being packaged, the desired shelf life, and the conditions the package will be exposed to during distribution and storage. Each type of polyethylene offers unique advantages that make it suitable for different aspects of food packaging, contributing to the versatility and widespread use of Food Grade PE Film in the global market. As the demand for safe and effective food packaging continues to grow, manufacturers are constantly exploring new ways to enhance the properties of these materials, ensuring they meet the evolving needs of consumers and the food industry.

Drinks, Food, Others in the Food Grade PE Film - Global Market:

Food Grade PE Film is extensively used in the packaging of drinks, food, and other products, each requiring specific properties to ensure the safety and quality of the packaged items. In the drinks sector, Food Grade PE Film is used to create secure and leak-proof packaging for a variety of beverages, including water, juices, and dairy products. The film's excellent moisture barrier properties help prevent contamination and spoilage, ensuring that the drinks remain fresh and safe for consumption. Additionally, the film's flexibility allows it to conform to different container shapes, providing a tight seal that prevents leaks and extends the shelf life of the beverages. In the food sector, Food Grade PE Film is used to package a wide range of products, from fresh produce to processed foods. Its ability to provide a protective barrier against moisture, oxygen, and other environmental factors helps preserve the quality and freshness of the food, reducing waste and enhancing consumer satisfaction. The film's transparency also allows consumers to see the product inside, which can be a key factor in purchasing decisions. Furthermore, Food Grade PE Film is used in the packaging of ready-to-eat meals and snacks, where its heat-sealing capabilities ensure that the packaging remains intact during transportation and storage. Beyond drinks and food, Food Grade PE Film is used in various other applications, such as the packaging of pharmaceuticals, personal care products, and household items. In these areas, the film's non-reactive nature and ability to provide a sterile barrier make it an ideal choice for protecting sensitive products from contamination and damage. The versatility of Food Grade PE Film in these diverse applications highlights its importance in the global market, where it plays a crucial role in ensuring the safety, quality, and convenience of packaged products. As consumer expectations for packaging continue to evolve, the demand for innovative and sustainable Food Grade PE Film solutions is expected to grow, driving further advancements in this dynamic market.

Food Grade PE Film - Global Market Outlook:

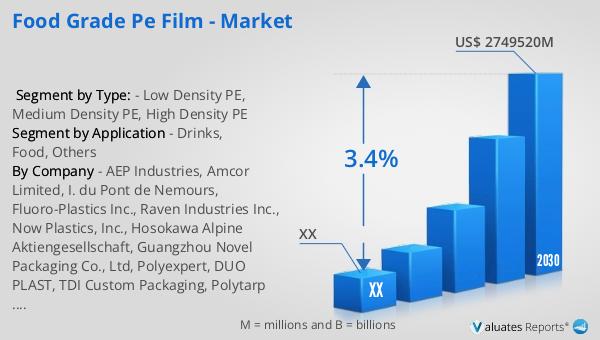

The global market outlook for Food Grade PE Film indicates a robust growth trajectory, with the market valued at approximately $2,186,340 million in 2023. This market is projected to expand to a size of $2,749,520 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for safe and effective food packaging solutions across the globe. In North America, the market for Food Grade PE Film is also expected to experience significant growth, although specific figures for this region were not provided. The anticipated growth in this market can be attributed to the rising consumer awareness regarding food safety and the increasing adoption of sustainable packaging materials. As the food and beverage industry continues to expand, the need for reliable and high-quality packaging solutions like Food Grade PE Film is expected to rise, further fueling market growth. The market's positive outlook is supported by ongoing innovations in film manufacturing technologies and the development of new formulations that enhance the film's protective qualities while maintaining its food safety credentials. As a result, the Food Grade PE Film market is poised for continued expansion, driven by the growing demand for packaging solutions that meet the evolving needs of consumers and the food industry.

| Report Metric | Details |

| Report Name | Food Grade PE Film - Market |

| Forecasted market size in 2030 | US$ 2749520 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | AEP Industries, Amcor Limited, I. du Pont de Nemours, Fluoro-Plastics Inc., Raven Industries Inc., Now Plastics, Inc., Hosokawa Alpine Aktiengesellschaft, Guangzhou Novel Packaging Co., Ltd, Polyexpert, DUO PLAST, TDI Custom Packaging, Polytarp Products, Respack Manufacturing Sdn Bhd, Teknika GROUP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |