What is Fire-resistant Ceramics - Global Market?

Fire-resistant ceramics are specialized materials designed to withstand high temperatures and prevent the spread of fire, making them essential in various industries. These ceramics are composed of compounds that can endure extreme heat without degrading, thus providing a protective barrier against fire. The global market for fire-resistant ceramics is driven by the increasing demand for safety and durability in construction, manufacturing, and other sectors. As industries continue to prioritize safety standards, the need for materials that can resist fire and maintain structural integrity becomes paramount. Fire-resistant ceramics are used in applications ranging from building materials to industrial equipment, where they help prevent catastrophic failures and enhance safety. The market is characterized by continuous innovation, with manufacturers developing new formulations to improve the performance and cost-effectiveness of these materials. As a result, fire-resistant ceramics are becoming more accessible and widely used across different regions, contributing to the growth of the global market. The increasing awareness of fire safety regulations and the need for sustainable materials further propel the demand for fire-resistant ceramics, making them a crucial component in modern industrial and construction practices.

Alumina Fire-resistant Ceramics, Magnesium Oxide Fire-resistant Ceramics, Aluminosilicate Fire-resistant Ceramics in the Fire-resistant Ceramics - Global Market:

Alumina fire-resistant ceramics are among the most widely used materials in the fire-resistant ceramics market due to their excellent thermal stability and mechanical strength. Alumina, or aluminum oxide, is known for its ability to withstand high temperatures and resist wear and corrosion, making it ideal for applications in industries such as metallurgy and chemical processing. These ceramics are often used in furnace linings, kilns, and other high-temperature environments where durability and resistance to thermal shock are critical. Magnesium oxide fire-resistant ceramics, on the other hand, offer exceptional thermal conductivity and are often used in applications requiring high thermal insulation. Magnesium oxide is particularly valued for its ability to withstand extreme temperatures without reacting with other materials, making it suitable for use in refractory linings and as a component in thermal insulation products. Aluminosilicate fire-resistant ceramics combine the properties of alumina and silica to provide a balance of thermal resistance and mechanical strength. These ceramics are commonly used in applications where both high temperature resistance and structural integrity are required, such as in the production of glass and ceramics. The global market for these materials is driven by the need for high-performance, cost-effective solutions that can meet the demanding requirements of modern industrial processes. As industries continue to evolve and demand more efficient and sustainable materials, the development and application of fire-resistant ceramics are expected to grow, offering new opportunities for innovation and market expansion.

Metallurgy, Chemical, Oil, Machinery Manufacturing, Others in the Fire-resistant Ceramics - Global Market:

Fire-resistant ceramics play a crucial role in various industries, providing essential protection and enhancing the safety and efficiency of operations. In the metallurgy industry, these ceramics are used to line furnaces, kilns, and other high-temperature equipment, where they help maintain the integrity of the structures and prevent heat loss. Their ability to withstand extreme temperatures and resist chemical reactions makes them indispensable in processes such as steelmaking and metal casting. In the chemical industry, fire-resistant ceramics are used in reactors, heat exchangers, and other equipment that operate under high temperatures and corrosive conditions. Their resistance to thermal shock and chemical attack ensures the longevity and reliability of the equipment, reducing maintenance costs and downtime. In the oil industry, fire-resistant ceramics are used in drilling and refining operations, where they provide thermal insulation and protect equipment from the harsh conditions of high-pressure, high-temperature environments. Their use in machinery manufacturing is also significant, as they help improve the performance and durability of components exposed to high temperatures and mechanical stress. Other applications of fire-resistant ceramics include their use in the construction of fireproof buildings and infrastructure, where they provide an additional layer of safety and protection. The versatility and effectiveness of fire-resistant ceramics make them an essential component in modern industrial practices, contributing to the overall safety, efficiency, and sustainability of operations across various sectors.

Fire-resistant Ceramics - Global Market Outlook:

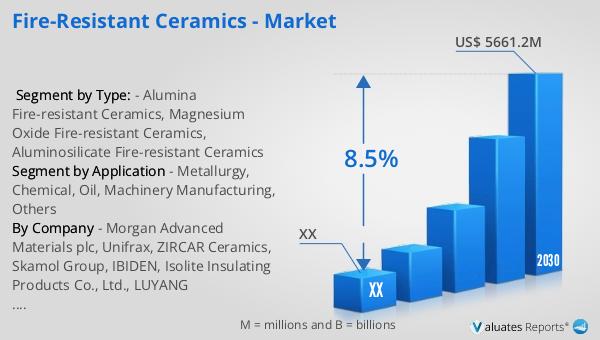

The global market for fire-resistant ceramics was valued at approximately $3,234 million in 2023, with projections indicating a growth to around $5,661.2 million by 2030. This represents a compound annual growth rate (CAGR) of 8.5% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to experience significant growth, although specific figures for this region were not provided. The increasing demand for fire-resistant ceramics is driven by the need for enhanced safety measures and the growing awareness of fire safety regulations across various industries. As more sectors recognize the importance of using materials that can withstand high temperatures and prevent fire-related incidents, the market for fire-resistant ceramics is poised for substantial expansion. The continuous development of new and improved ceramic formulations further supports this growth, offering industries more efficient and cost-effective solutions to meet their fire safety needs. As a result, the global market for fire-resistant ceramics is expected to continue its upward trajectory, driven by innovation, regulatory requirements, and the increasing emphasis on safety and sustainability in industrial practices.

| Report Metric | Details |

| Report Name | Fire-resistant Ceramics - Market |

| Forecasted market size in 2030 | US$ 5661.2 million |

| CAGR | 8.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Morgan Advanced Materials plc, Unifrax, ZIRCAR Ceramics, Skamol Group, IBIDEN, Isolite Insulating Products Co., Ltd., LUYANG ENERGY-SAVING MATERIALS CO., LTD, Rath Incorporated, NGP Industries, Vecor Technologies, SCHOTT, Jay Agenciez |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |