What is Carbon Fiber Reinforced Plastics (CFRP) for Automobiles - Global Market?

Carbon Fiber Reinforced Plastics (CFRP) are a composite material made by combining carbon fibers with a plastic matrix, typically epoxy. These materials are known for their high strength-to-weight ratio, making them ideal for use in the automotive industry. CFRP is used to manufacture various automobile components, including body panels, chassis, and interior parts. The global market for CFRP in automobiles is driven by the increasing demand for lightweight materials that improve fuel efficiency and reduce emissions. As automakers strive to meet stringent environmental regulations and consumer demand for more efficient vehicles, the use of CFRP is expected to grow. The material's ability to reduce vehicle weight without compromising strength or safety makes it an attractive option for manufacturers. Additionally, advancements in manufacturing processes and the development of cost-effective production techniques are expected to further boost the adoption of CFRP in the automotive sector. The global market for CFRP in automobiles is poised for significant growth as manufacturers continue to explore innovative ways to incorporate these materials into their designs.

Thermosetting Carbon Fiber Reinforced Plastics, Thermoplastic Carbon Fiber Reinforced Plastics in the Carbon Fiber Reinforced Plastics (CFRP) for Automobiles - Global Market:

Thermosetting Carbon Fiber Reinforced Plastics (CFRP) and Thermoplastic Carbon Fiber Reinforced Plastics are two primary types of CFRP used in the automotive industry. Thermosetting CFRP is made by combining carbon fibers with a thermosetting resin, such as epoxy. Once cured, this type of CFRP is highly resistant to heat and chemicals, making it suitable for high-performance applications. It is commonly used in structural components, such as chassis and body panels, where strength and durability are critical. The curing process for thermosetting CFRP involves a chemical reaction that creates a rigid, inflexible structure. This makes it ideal for applications where dimensional stability and resistance to deformation are important. On the other hand, Thermoplastic CFRP is made by combining carbon fibers with a thermoplastic resin, such as polypropylene. Unlike thermosetting CFRP, thermoplastic CFRP can be melted and reformed multiple times, allowing for greater flexibility in manufacturing processes. This type of CFRP is often used in applications where complex shapes and designs are required, such as interior components and trim. The ability to reshape thermoplastic CFRP makes it an attractive option for automakers looking to streamline production and reduce costs. Both types of CFRP offer unique advantages and are used in different applications within the automotive industry. The choice between thermosetting and thermoplastic CFRP depends on the specific requirements of the application, including factors such as strength, weight, and manufacturing complexity. As the demand for lightweight materials continues to grow, both thermosetting and thermoplastic CFRP are expected to play a significant role in the future of automotive manufacturing. The global market for CFRP in automobiles is driven by the need for materials that can improve fuel efficiency and reduce emissions. As automakers strive to meet these goals, the use of CFRP is expected to increase, with both thermosetting and thermoplastic options offering valuable solutions. The versatility and performance characteristics of CFRP make it an ideal choice for a wide range of automotive applications, from high-performance sports cars to everyday passenger vehicles. As technology advances and production costs decrease, the adoption of CFRP in the automotive industry is likely to accelerate, leading to further innovations and improvements in vehicle design and performance.

Commercial Vehicle, Passenger Vehicle in the Carbon Fiber Reinforced Plastics (CFRP) for Automobiles - Global Market:

The use of Carbon Fiber Reinforced Plastics (CFRP) in the automotive industry is expanding across various segments, including commercial and passenger vehicles. In commercial vehicles, CFRP is primarily used to reduce weight and improve fuel efficiency. These vehicles, such as trucks and buses, often have large bodies and carry heavy loads, making weight reduction a critical factor in improving performance and reducing operational costs. By incorporating CFRP into components like chassis, body panels, and cargo areas, manufacturers can significantly reduce the overall weight of the vehicle, leading to better fuel economy and lower emissions. Additionally, the high strength-to-weight ratio of CFRP ensures that these vehicles maintain their structural integrity and safety standards. In passenger vehicles, CFRP is used to enhance performance, safety, and aesthetics. Sports cars and luxury vehicles often utilize CFRP for its lightweight properties, which contribute to faster acceleration, improved handling, and increased fuel efficiency. The material is also used in safety-critical components, such as crash structures and roll cages, where its strength and energy absorption capabilities provide enhanced protection for occupants. Furthermore, CFRP's unique appearance and ability to be molded into complex shapes make it a popular choice for interior and exterior design elements, adding a touch of sophistication and exclusivity to high-end vehicles. As consumer demand for more efficient and environmentally friendly vehicles grows, the use of CFRP in both commercial and passenger vehicles is expected to increase. Automakers are continually exploring new ways to incorporate this advanced material into their designs, driven by the need to meet stringent emissions regulations and improve vehicle performance. The global market for CFRP in automobiles is poised for significant growth as manufacturers seek to leverage the benefits of this innovative material. By reducing weight and enhancing performance, CFRP plays a crucial role in the development of next-generation vehicles that meet the demands of modern consumers and regulatory bodies. As technology advances and production costs decrease, the adoption of CFRP in the automotive industry is likely to accelerate, leading to further innovations and improvements in vehicle design and performance.

Carbon Fiber Reinforced Plastics (CFRP) for Automobiles - Global Market Outlook:

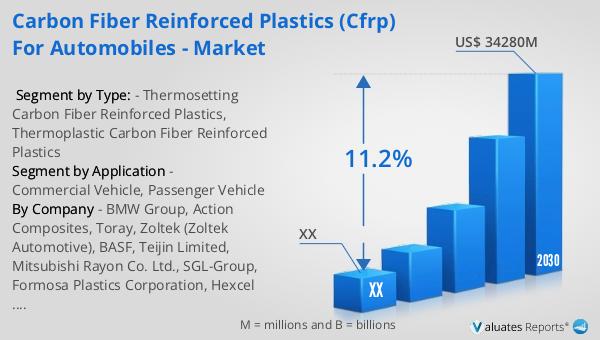

The global market for Carbon Fiber Reinforced Plastics (CFRP) in automobiles was valued at approximately $15,980 million in 2023. It is projected to grow to a revised size of $34,280 million by 2030, reflecting a compound annual growth rate (CAGR) of 11.2% during the forecast period from 2024 to 2030. Currently, over 90% of the world's automobiles are concentrated in Asia, Europe, and North America. Asia leads the way in automobile production, accounting for 56% of the global output. Europe follows with a 20% share, while North America contributes 16%. This regional concentration highlights the significant role these continents play in the automotive industry and the potential for growth in the CFRP market. As automakers in these regions continue to seek innovative solutions to meet consumer demands and regulatory requirements, the adoption of CFRP is expected to increase. The material's ability to reduce vehicle weight, improve fuel efficiency, and enhance performance makes it an attractive option for manufacturers looking to stay competitive in a rapidly evolving market. As the global market for CFRP in automobiles continues to expand, manufacturers are likely to explore new applications and technologies to further leverage the benefits of this advanced material.

| Report Metric | Details |

| Report Name | Carbon Fiber Reinforced Plastics (CFRP) for Automobiles - Market |

| Forecasted market size in 2030 | US$ 34280 million |

| CAGR | 11.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BMW Group, Action Composites, Toray, Zoltek (Zoltek Automotive), BASF, Teijin Limited, Mitsubishi Rayon Co. Ltd., SGL-Group, Formosa Plastics Corporation, Hexcel Corporation, Roding Automobile GmbH, Carbon Composites (PCC), Americhem |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |