What is Aviation Grade Carbon Fiber - Global Market?

Aviation Grade Carbon Fiber is a specialized material that has become increasingly important in the aerospace industry due to its exceptional strength-to-weight ratio, durability, and resistance to environmental factors. This type of carbon fiber is used extensively in the manufacturing of aircraft components, where reducing weight without compromising strength is crucial. The global market for Aviation Grade Carbon Fiber is driven by the growing demand for fuel-efficient aircraft, as lighter materials contribute to lower fuel consumption and reduced emissions. Additionally, advancements in carbon fiber production technologies have made it more cost-effective, further boosting its adoption in the aviation sector. The market is characterized by a high level of innovation, with manufacturers continuously developing new grades and forms of carbon fiber to meet the evolving needs of the aerospace industry. As a result, Aviation Grade Carbon Fiber is not only used in commercial and military aircraft but also in other aerospace applications, such as satellites and unmanned aerial vehicles. The increasing focus on sustainability and the need for lightweight materials in the aviation industry are expected to drive the growth of this market in the coming years.

PAN Based Carbon Fiber, Pitch Based Carbon Fiber in the Aviation Grade Carbon Fiber - Global Market:

PAN Based Carbon Fiber and Pitch Based Carbon Fiber are two primary types of carbon fibers used in the aviation industry, each with distinct properties and applications. PAN (Polyacrylonitrile) Based Carbon Fiber is the most widely used type due to its high tensile strength and modulus, making it ideal for structural components in aircraft. The production process involves stabilizing, carbonizing, and graphitizing PAN precursor fibers, resulting in a material that is lightweight yet incredibly strong. This type of carbon fiber is often used in the construction of aircraft fuselages, wings, and other critical components where strength and weight are paramount. On the other hand, Pitch Based Carbon Fiber is derived from petroleum or coal tar pitch and is known for its high thermal conductivity and modulus. Although it is less commonly used than PAN Based Carbon Fiber, it is preferred in applications where thermal management is crucial, such as in heat shields and other high-temperature components. The choice between PAN and Pitch Based Carbon Fiber depends on the specific requirements of the application, including mechanical properties, thermal performance, and cost considerations. In the global market for Aviation Grade Carbon Fiber, both types play a significant role, with manufacturers continually exploring new ways to enhance their properties and reduce production costs. The demand for PAN Based Carbon Fiber is primarily driven by its widespread use in commercial and military aircraft, while Pitch Based Carbon Fiber finds niche applications in specialized aerospace components. As the aviation industry continues to evolve, the development of new carbon fiber technologies and the exploration of hybrid materials are expected to further expand the applications of these advanced materials. The global market for Aviation Grade Carbon Fiber is characterized by intense competition among manufacturers, with companies investing heavily in research and development to gain a competitive edge. This has led to the introduction of innovative products and processes that enhance the performance and cost-effectiveness of carbon fiber materials. Additionally, collaborations between carbon fiber manufacturers and aerospace companies are becoming increasingly common, as they work together to develop customized solutions that meet the specific needs of the aviation industry. The growing emphasis on sustainability and the need for lightweight materials in the aviation sector are also driving the development of eco-friendly carbon fiber production methods, which aim to reduce the environmental impact of manufacturing processes. Overall, the global market for Aviation Grade Carbon Fiber is poised for significant growth, driven by the increasing demand for lightweight, high-performance materials in the aerospace industry.

Commercial Aircraft, Military Aircraft, Others in the Aviation Grade Carbon Fiber - Global Market:

Aviation Grade Carbon Fiber is extensively used in various areas of the aviation industry, including commercial aircraft, military aircraft, and other aerospace applications. In commercial aircraft, carbon fiber is primarily used to reduce weight and improve fuel efficiency. The material's high strength-to-weight ratio allows for the construction of lighter aircraft structures, which in turn leads to lower fuel consumption and reduced emissions. This is particularly important in the commercial aviation sector, where airlines are constantly seeking ways to improve operational efficiency and reduce costs. Carbon fiber is used in the construction of aircraft fuselages, wings, and tail sections, as well as in interior components such as seats and overhead bins. In military aircraft, the use of Aviation Grade Carbon Fiber is driven by the need for high-performance materials that can withstand extreme conditions. Carbon fiber's exceptional strength and durability make it ideal for use in fighter jets, helicopters, and other military aircraft, where it is used in the construction of airframes, rotor blades, and other critical components. The material's resistance to corrosion and fatigue also makes it suitable for use in harsh environments, such as those encountered in military operations. In addition to commercial and military aircraft, Aviation Grade Carbon Fiber is also used in other aerospace applications, such as satellites and unmanned aerial vehicles (UAVs). In these applications, the material's lightweight properties are particularly advantageous, as they allow for the construction of lighter and more efficient structures. Carbon fiber is used in the construction of satellite components, such as antennae and solar panels, as well as in the airframes and propulsion systems of UAVs. The versatility and performance of Aviation Grade Carbon Fiber make it an essential material in the aerospace industry, where it is used to enhance the performance and efficiency of a wide range of aircraft and aerospace systems. As the demand for lightweight, high-performance materials continues to grow, the use of carbon fiber in the aviation industry is expected to expand, driven by advancements in material science and manufacturing technologies.

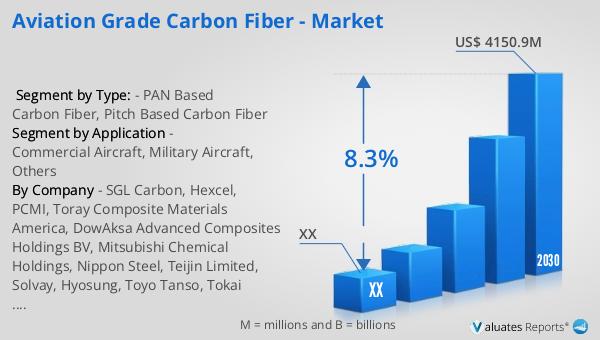

Aviation Grade Carbon Fiber - Global Market Outlook:

The global market for Aviation Grade Carbon Fiber was valued at approximately $2,356 million in 2023 and is projected to grow significantly, reaching an estimated $4,150.9 million by 2030. This growth represents a compound annual growth rate (CAGR) of 8.3% during the forecast period from 2024 to 2030. The North American market, a key region for aviation-grade carbon fiber, also shows promising growth potential. Although specific figures for the North American market in 2023 and 2030 are not provided, the region is expected to experience a steady increase in demand, driven by the presence of major aerospace manufacturers and ongoing advancements in carbon fiber technology. The growth in the global market is attributed to several factors, including the increasing demand for fuel-efficient aircraft, the rising adoption of carbon fiber in various aerospace applications, and the continuous development of new carbon fiber grades and forms. Additionally, the focus on sustainability and the need for lightweight materials in the aviation industry are expected to further drive market growth. As manufacturers continue to innovate and collaborate with aerospace companies, the global market for Aviation Grade Carbon Fiber is poised for substantial expansion in the coming years.

| Report Metric | Details |

| Report Name | Aviation Grade Carbon Fiber - Market |

| Forecasted market size in 2030 | US$ 4150.9 million |

| CAGR | 8.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SGL Carbon, Hexcel, PCMI, Toray Composite Materials America, DowAksa Advanced Composites Holdings BV, Mitsubishi Chemical Holdings, Nippon Steel, Teijin Limited, Solvay, Hyosung, Toyo Tanso, Tokai Carbon, Nippon Carbon, MERSEN BENELUX, Schunk, Americarb, Carbon Composites, FMI, Luhang Carbon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |