What is Antistatic Fabric - Global Market?

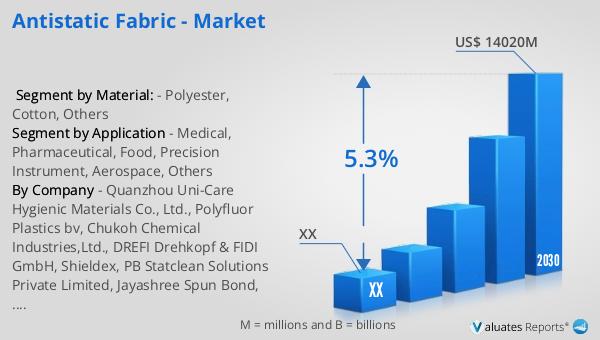

Antistatic fabric is a specialized material designed to prevent the buildup of static electricity. This fabric is crucial in environments where static discharge can pose a risk, such as in electronics manufacturing, cleanrooms, and certain industrial settings. The global market for antistatic fabric is vast and growing, driven by increasing demand across various sectors. In 2023, the market was valued at approximately US$ 9,675 million. By 2030, it is projected to reach a size of US$ 14,020 million, growing at a compound annual growth rate (CAGR) of 5.3% from 2024 to 2030. This growth is fueled by the fabric's ability to enhance safety and comfort by minimizing static electricity, which can otherwise lead to discomfort, equipment malfunction, or even explosions in volatile environments. The fabric's functionality makes it indispensable in industries where precision and safety are paramount. As technology advances and industries become more aware of the risks associated with static electricity, the demand for antistatic fabric is expected to continue its upward trajectory, making it a critical component in the global textile market.

in the Antistatic Fabric - Global Market:

Antistatic fabrics come in various types, each tailored to meet the specific needs of different industries and applications. One common type is woven antistatic fabric, which is made by interlacing yarns that have conductive fibers. These fibers help dissipate static electricity, making the fabric suitable for environments where static discharge could damage sensitive electronic components. Another type is knitted antistatic fabric, which offers flexibility and comfort, making it ideal for garments worn in static-sensitive areas. This type of fabric is often used in the production of workwear for industries like electronics and telecommunications. Non-woven antistatic fabrics are also popular, particularly in the medical and hygiene sectors. These fabrics are made by bonding fibers together, rather than weaving or knitting them, and are often used in disposable products like surgical gowns and masks. Additionally, there are coated antistatic fabrics, which have a surface treatment that enhances their static-dissipative properties. These are often used in environments where the fabric needs to be both antistatic and resistant to chemicals or other harsh conditions. Each type of antistatic fabric is designed to meet specific performance criteria, ensuring that it provides the necessary protection and functionality for its intended use. The choice of fabric type depends on factors such as the level of static protection required, the environmental conditions, and the specific application. As industries continue to evolve and new applications for antistatic fabrics emerge, manufacturers are constantly innovating to develop fabrics that meet the changing needs of their customers. This ongoing innovation is a key driver of growth in the global antistatic fabric market, as it enables manufacturers to offer a wider range of products that cater to the diverse requirements of different industries.

Medical, Pharmaceutical, Food, Precision Instrument, Aerospace, Others in the Antistatic Fabric - Global Market:

Antistatic fabrics are used in a wide range of applications across various industries, each with its own specific requirements and challenges. In the medical field, antistatic fabrics are essential for preventing static discharge that could interfere with sensitive medical equipment or ignite flammable substances. These fabrics are used in the production of surgical gowns, drapes, and other protective clothing, ensuring that healthcare professionals can work safely and effectively. In the pharmaceutical industry, antistatic fabrics are used to prevent contamination and ensure the integrity of products. They are often used in cleanroom environments, where maintaining a controlled atmosphere is critical to the production of high-quality pharmaceuticals. In the food industry, antistatic fabrics help prevent the buildup of static electricity that could attract dust and other contaminants, ensuring that food products remain safe and hygienic. These fabrics are used in the production of workwear and other protective clothing for food processing and handling. In the precision instrument industry, antistatic fabrics are used to protect sensitive equipment from static discharge, which could cause malfunctions or damage. These fabrics are used in the production of protective covers and other accessories for precision instruments. In the aerospace industry, antistatic fabrics are used to protect sensitive electronic components and systems from static discharge, ensuring the safety and reliability of aircraft and spacecraft. These fabrics are used in the production of protective clothing and other equipment for aerospace applications. In addition to these industries, antistatic fabrics are also used in a variety of other applications, including automotive, electronics, and telecommunications. The versatility and effectiveness of antistatic fabrics make them an essential component in many industries, helping to ensure safety, reliability, and performance.

Antistatic Fabric - Global Market Outlook:

The global market for antistatic fabric was valued at approximately US$ 9,675 million in 2023, and it is anticipated to grow to a size of US$ 14,020 million by 2030, with a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. Antistatic fabric is a functional material that possesses antistatic properties, significantly reducing the generation and accumulation of static electricity. This reduction in static electricity enhances both the comfort and safety of the wearer, making it a crucial component in various industries. The fabric's ability to prevent static discharge is particularly important in environments where such discharges could lead to equipment malfunctions, contamination, or even explosions. As industries become more aware of the risks associated with static electricity, the demand for antistatic fabric is expected to continue growing. This growth is driven by the fabric's ability to provide a safer and more comfortable working environment, as well as its versatility in meeting the needs of different industries. The ongoing innovation in antistatic fabric technology is also contributing to market growth, as manufacturers develop new products that offer enhanced performance and functionality. As a result, the global market for antistatic fabric is poised for continued expansion, making it an important area of focus for manufacturers and industry stakeholders.

| Report Metric | Details |

| Report Name | Antistatic Fabric - Market |

| Forecasted market size in 2030 | US$ 14020 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Material: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Quanzhou Uni-Care Hygienic Materials Co., Ltd., Polyfluor Plastics bv, Chukoh Chemical Industries,Ltd., DREFI Drehkopf & FIDI GmbH, Shieldex, PB Statclean Solutions Private Limited, Jayashree Spun Bond, Global Statclean Systems, Arrow Technical Textiles Private Limited, Klopman, Mafatlal Gujarat Industries, Micron Teknik Tekstil, Fabrics India |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |