What is Wood Impregnation Equipment - Global Market?

Wood impregnation equipment is a specialized machinery used in the treatment of wood to enhance its durability, resistance to decay, and overall performance. This equipment is crucial in the wood processing industry as it allows for the impregnation of wood with various chemicals, such as preservatives, fire retardants, and water repellents. The global market for wood impregnation equipment is driven by the increasing demand for treated wood in construction, furniture, and other applications where enhanced wood properties are desirable. The equipment works by applying pressure to force the chemical solutions deep into the wood fibers, ensuring thorough treatment. This process not only extends the lifespan of the wood but also improves its structural integrity and aesthetic appeal. As environmental concerns and regulations become more stringent, the market is also seeing a shift towards more eco-friendly impregnation solutions, which is influencing the development and adoption of advanced wood impregnation technologies. The market is characterized by a mix of established players and new entrants, all striving to offer innovative solutions that meet the evolving needs of the wood processing industry.

Dry Type, Wet Type in the Wood Impregnation Equipment - Global Market:

Wood impregnation equipment can be broadly categorized into two types: dry type and wet type, each serving distinct purposes and offering unique benefits. The dry type wood impregnation equipment is designed to treat wood without the use of liquid chemicals. Instead, it utilizes gaseous or vaporized chemicals to penetrate the wood fibers. This method is particularly advantageous for treating wood that will be used in environments where moisture is a concern, as it minimizes the risk of swelling or warping. The dry type equipment is often preferred for its efficiency and the reduced environmental impact, as it typically requires less chemical usage and generates minimal waste. On the other hand, wet type wood impregnation equipment involves the use of liquid chemicals to treat the wood. This method is highly effective for deep penetration of preservatives and is commonly used for outdoor applications where wood is exposed to harsh weather conditions. The wet type equipment is known for its ability to provide comprehensive protection against decay, insects, and other damaging factors. However, it requires careful handling and disposal of chemicals to prevent environmental contamination. Both types of equipment are essential in the global market, catering to different needs and preferences of wood processing industries. The choice between dry and wet type equipment often depends on the specific requirements of the wood treatment process, the desired properties of the treated wood, and environmental considerations. As the demand for treated wood continues to rise, manufacturers are focusing on developing more efficient and sustainable wood impregnation technologies. This includes innovations in chemical formulations, equipment design, and process automation to enhance the effectiveness and eco-friendliness of wood impregnation. The global market for wood impregnation equipment is witnessing a steady growth, driven by the increasing awareness of the benefits of treated wood and the need for sustainable wood processing solutions. As industries continue to seek ways to improve the quality and longevity of wood products, the demand for both dry and wet type wood impregnation equipment is expected to remain strong.

Log Processing, Wood Processing, Others in the Wood Impregnation Equipment - Global Market:

Wood impregnation equipment plays a vital role in various areas such as log processing, wood processing, and other related applications. In log processing, the equipment is used to treat logs before they are cut into lumber or other wood products. This initial treatment helps in preserving the logs during storage and transportation, preventing decay and insect infestation. By ensuring the logs remain in good condition, wood impregnation equipment contributes to the overall quality and yield of the final wood products. In wood processing, the equipment is used to treat lumber, plywood, and other wood products to enhance their durability and resistance to environmental factors. This is particularly important for wood used in construction, furniture, and outdoor applications, where exposure to moisture, insects, and other damaging elements is a concern. The use of wood impregnation equipment in wood processing not only extends the lifespan of the products but also improves their performance and aesthetic appeal. Additionally, the equipment is used in other applications such as the treatment of utility poles, railway sleepers, and marine pilings, where enhanced wood properties are critical for safety and longevity. The versatility of wood impregnation equipment makes it an indispensable tool in the wood processing industry, catering to a wide range of applications and requirements. As industries continue to prioritize sustainability and environmental responsibility, the demand for advanced wood impregnation equipment is expected to grow. Manufacturers are focusing on developing innovative solutions that offer improved efficiency, reduced chemical usage, and minimal environmental impact. This includes the use of eco-friendly chemicals, advanced automation, and process optimization to enhance the effectiveness and sustainability of wood impregnation. The global market for wood impregnation equipment is poised for growth, driven by the increasing demand for treated wood in various applications and the need for sustainable wood processing solutions. As industries continue to seek ways to improve the quality and longevity of wood products, the role of wood impregnation equipment in log processing, wood processing, and other applications will remain crucial.

Wood Impregnation Equipment - Global Market Outlook:

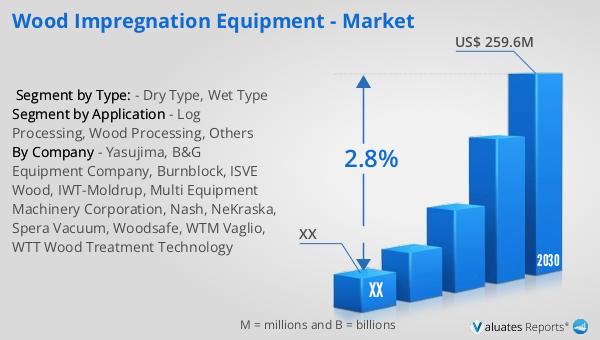

The global market for wood impregnation equipment was valued at approximately $204 million in 2023 and is projected to grow to around $259.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for treated wood across various industries, driven by the need for enhanced durability and performance of wood products. The North American market, in particular, is expected to see significant growth, although specific figures were not provided. The steady increase in market size highlights the importance of wood impregnation equipment in meeting the evolving needs of the wood processing industry. As environmental regulations become more stringent and the demand for sustainable wood products rises, the market is likely to see further advancements in technology and innovation. Manufacturers are focusing on developing more efficient and eco-friendly solutions to cater to the growing demand for treated wood. The market outlook suggests a positive trajectory for the wood impregnation equipment industry, with opportunities for growth and development in various regions. As industries continue to prioritize sustainability and environmental responsibility, the role of wood impregnation equipment in enhancing the quality and longevity of wood products will remain crucial.

| Report Metric | Details |

| Report Name | Wood Impregnation Equipment - Market |

| Forecasted market size in 2030 | US$ 259.6 million |

| CAGR | 2.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Yasujima, B&G Equipment Company, Burnblock, ISVE Wood, IWT-Moldrup, Multi Equipment Machinery Corporation, Nash, NeKraska, Spera Vacuum, Woodsafe, WTM Vaglio, WTT Wood Treatment Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |