What is High Speed Paddle Dryer - Global Market?

High-speed paddle dryers are specialized industrial machines used to remove moisture from various materials through a process of heat transfer and mechanical agitation. These dryers are designed to handle a wide range of materials, including powders, granules, and pastes, making them versatile for different industries. The global market for high-speed paddle dryers is driven by the increasing demand for efficient drying solutions in sectors such as pharmaceuticals, food processing, and chemicals. These dryers offer several advantages, including energy efficiency, uniform drying, and the ability to handle heat-sensitive materials without degradation. The market is characterized by technological advancements aimed at improving the performance and efficiency of these dryers. Manufacturers are focusing on developing innovative designs that enhance heat transfer rates and reduce energy consumption. Additionally, the growing emphasis on sustainability and environmental regulations is pushing companies to adopt dryers that minimize emissions and energy usage. As industries continue to seek cost-effective and reliable drying solutions, the demand for high-speed paddle dryers is expected to grow, making it a significant segment in the global drying equipment market.

Vertical Type, Horizontal Type in the High Speed Paddle Dryer - Global Market:

High-speed paddle dryers come in two main configurations: vertical and horizontal types, each with distinct features and applications. The vertical type high-speed paddle dryer is designed with a vertical cylindrical body where the paddles are mounted on a central shaft. This configuration is particularly advantageous for materials that require gentle handling and minimal shear forces. The vertical design allows for efficient mixing and drying of materials with varying viscosities, making it suitable for applications in the pharmaceutical and food industries where product integrity is crucial. The vertical type is also known for its compact footprint, which is beneficial in facilities with limited space. On the other hand, the horizontal type high-speed paddle dryer features a horizontal cylindrical body with paddles attached to a rotating shaft. This design is ideal for materials that require more aggressive mixing and higher shear forces to achieve uniform drying. The horizontal configuration is often used in the chemical industry, where robust mixing and drying of bulk materials are necessary. It provides excellent heat transfer efficiency and can handle large volumes of material, making it suitable for high-capacity operations. Both vertical and horizontal types are equipped with advanced control systems that allow precise regulation of temperature, speed, and drying time, ensuring optimal performance and product quality. The choice between vertical and horizontal types depends on the specific requirements of the application, including the nature of the material, desired drying characteristics, and available space. Manufacturers are continually innovating to enhance the capabilities of both types, incorporating features such as improved paddle designs, enhanced heat exchangers, and automated control systems. These advancements aim to increase drying efficiency, reduce energy consumption, and improve the overall reliability of the equipment. As industries continue to evolve and demand more efficient drying solutions, the market for both vertical and horizontal high-speed paddle dryers is expected to expand, driven by the need for versatile and reliable drying technologies.

Pharmaceutical, Food, Chemical, Others in the High Speed Paddle Dryer - Global Market:

High-speed paddle dryers are extensively used across various industries, including pharmaceuticals, food, chemicals, and others, due to their efficiency and versatility. In the pharmaceutical industry, these dryers are crucial for drying active pharmaceutical ingredients (APIs) and other sensitive materials. The gentle mixing and precise temperature control offered by high-speed paddle dryers ensure that the integrity and efficacy of the pharmaceutical products are maintained. This is particularly important for heat-sensitive compounds that require careful handling to prevent degradation. In the food industry, high-speed paddle dryers are used to dry a wide range of products, from grains and cereals to fruits and vegetables. The ability to achieve uniform drying without compromising the nutritional value or flavor of the food products makes these dryers an essential tool in food processing. They are also used for drying food additives and ingredients, ensuring consistency and quality in the final products. In the chemical industry, high-speed paddle dryers are employed for drying various chemicals, including polymers, resins, and pigments. The robust design and high shear capabilities of these dryers make them suitable for handling challenging materials that require thorough mixing and drying. Additionally, the chemical industry benefits from the energy efficiency and reduced drying times offered by high-speed paddle dryers, which contribute to cost savings and increased productivity. Beyond these industries, high-speed paddle dryers find applications in sectors such as waste management, where they are used to dry sludge and other waste materials, reducing volume and facilitating disposal. The versatility and efficiency of high-speed paddle dryers make them a valuable asset in any industry that requires reliable and effective drying solutions. As industries continue to seek ways to improve efficiency and reduce environmental impact, the demand for high-speed paddle dryers is expected to grow, driven by their ability to deliver consistent and high-quality drying performance.

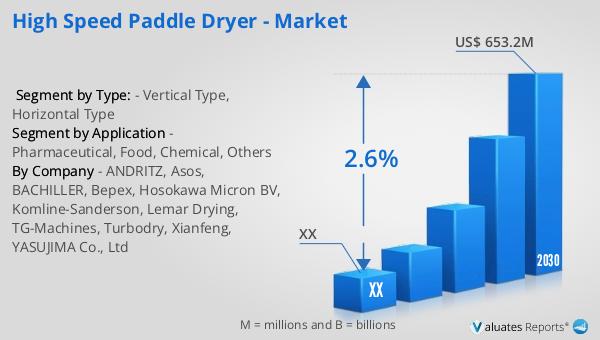

High Speed Paddle Dryer - Global Market Outlook:

The global market for high-speed paddle dryers was valued at approximately $488 million in 2023, and it is projected to grow to around $653.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and versatile drying solutions across various industries. In North America, the market for high-speed paddle dryers is also expected to experience growth, although specific figures for the region were not provided. The anticipated growth in the global market can be attributed to several factors, including technological advancements, the need for energy-efficient drying solutions, and the expanding applications of high-speed paddle dryers in industries such as pharmaceuticals, food processing, and chemicals. As companies continue to focus on improving productivity and reducing operational costs, the adoption of high-speed paddle dryers is likely to increase. The market outlook suggests a positive trajectory for the high-speed paddle dryer industry, driven by the ongoing demand for innovative and reliable drying technologies.

| Report Metric | Details |

| Report Name | High Speed Paddle Dryer - Market |

| Forecasted market size in 2030 | US$ 653.2 million |

| CAGR | 2.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ANDRITZ, Asos, BACHILLER, Bepex, Hosokawa Micron BV, Komline-Sanderson, Lemar Drying, TG-Machines, Turbodry, Xianfeng, YASUJIMA Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |