What is Industrial Robotics in Lithium Battery - Global Market?

Industrial robotics in the lithium battery global market refers to the use of automated machines and systems to enhance the production and efficiency of lithium batteries. These robots are designed to perform tasks that are repetitive, precise, and require high levels of accuracy, which are essential in the manufacturing of lithium batteries. The integration of robotics in this sector is driven by the increasing demand for lithium batteries, which are crucial components in various applications such as electric vehicles, consumer electronics, and renewable energy storage systems. Industrial robots help in streamlining the production process, reducing human error, and increasing the overall output of lithium batteries. They are employed in various stages of battery production, including material handling, assembly, welding, and quality inspection. The global market for industrial robotics in lithium battery manufacturing is expanding as companies seek to improve their production capabilities and meet the growing demand for high-performance batteries. This growth is supported by advancements in robotic technologies, which offer enhanced capabilities and flexibility in manufacturing processes. As a result, the adoption of industrial robotics in the lithium battery sector is expected to continue rising, contributing to the efficiency and competitiveness of battery manufacturers worldwide.

SCARA Industrial Robots, 6-Axis Industrial Robots, Others in the Industrial Robotics in Lithium Battery - Global Market:

SCARA (Selective Compliance Assembly Robot Arm) industrial robots, 6-axis industrial robots, and other types of robots play a significant role in the lithium battery global market. SCARA robots are known for their speed and precision, making them ideal for tasks such as assembly and material handling in battery production. They have a unique design that allows them to operate in a horizontal plane, providing flexibility and efficiency in performing repetitive tasks. SCARA robots are particularly useful in applications where high-speed pick-and-place operations are required, such as assembling battery cells and modules. Their compact design also makes them suitable for use in confined spaces, which is often the case in battery manufacturing facilities. On the other hand, 6-axis industrial robots offer greater versatility and range of motion compared to SCARA robots. They are capable of performing complex tasks that require multiple degrees of freedom, such as welding and inspection. These robots can manipulate objects in three-dimensional space, allowing them to handle intricate operations with precision. In the context of lithium battery production, 6-axis robots are often used for tasks that require a high level of dexterity, such as welding battery components and performing quality checks. Their ability to adapt to different tasks makes them valuable assets in the manufacturing process, as they can be reprogrammed to perform various functions as needed. Other types of industrial robots used in the lithium battery market include collaborative robots, or cobots, which are designed to work alongside human operators. Cobots are equipped with advanced sensors and safety features that allow them to operate safely in close proximity to humans. They are often used in tasks that require human-robot collaboration, such as assembly and quality control. The use of cobots in battery production can enhance productivity by combining the strengths of human workers and robotic systems. Additionally, autonomous mobile robots (AMRs) are increasingly being used for material transport and logistics within battery manufacturing facilities. These robots can navigate autonomously through the production floor, transporting materials and components between different stages of the manufacturing process. AMRs help streamline operations and reduce the need for manual labor in material handling, contributing to increased efficiency and reduced production costs. Overall, the integration of various types of industrial robots in the lithium battery global market is driven by the need for increased efficiency, precision, and flexibility in manufacturing processes. As the demand for lithium batteries continues to grow, the adoption of advanced robotic technologies is expected to play a crucial role in meeting production requirements and maintaining competitiveness in the market.

Material Handling, Welding, Assembly, Detection, Others in the Industrial Robotics in Lithium Battery - Global Market:

The usage of industrial robotics in the lithium battery global market spans several key areas, including material handling, welding, assembly, detection, and other applications. In material handling, robots are employed to transport raw materials, components, and finished products throughout the production facility. This automation reduces the need for manual labor, minimizes the risk of human error, and increases the overall efficiency of the manufacturing process. Robots equipped with advanced sensors and navigation systems can move materials quickly and accurately, ensuring a smooth flow of production. In welding, industrial robots are used to join battery components with precision and consistency. Robotic welding systems offer several advantages over manual welding, including higher accuracy, faster processing times, and improved safety. These systems can perform complex welding tasks with minimal supervision, ensuring that battery components are securely joined and meet quality standards. In the assembly process, robots are used to assemble battery cells and modules with high precision. Automated assembly systems can handle delicate components with care, reducing the risk of damage and ensuring that each battery is assembled to exact specifications. This level of precision is crucial in maintaining the performance and reliability of lithium batteries. Detection and inspection are also critical areas where industrial robotics are utilized. Robots equipped with advanced vision systems and sensors can perform quality checks on battery components and finished products, identifying defects and ensuring that only high-quality batteries are released to the market. This automation enhances the overall quality control process, reducing the likelihood of defective products reaching consumers. Other applications of industrial robotics in the lithium battery market include tasks such as coating, packaging, and testing. Robots can apply protective coatings to battery components, ensuring durability and longevity. In packaging, robots can efficiently pack batteries for shipment, reducing the risk of damage during transportation. Automated testing systems can perform rigorous tests on batteries to ensure they meet performance and safety standards. The integration of industrial robotics in these areas not only improves efficiency and productivity but also enhances the overall quality and reliability of lithium batteries. As the demand for high-performance batteries continues to rise, the use of advanced robotic technologies is expected to play a crucial role in meeting production requirements and maintaining competitiveness in the market.

Industrial Robotics in Lithium Battery - Global Market Outlook:

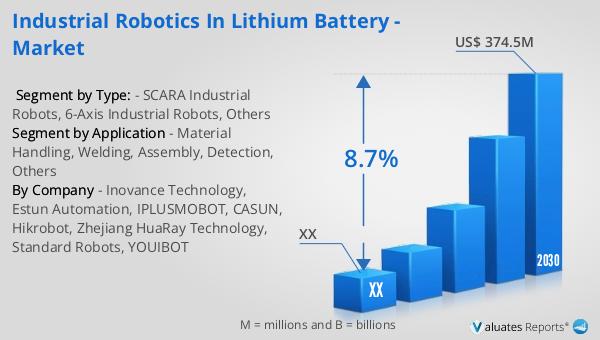

In 2023, the global market for industrial robotics in the lithium battery sector was valued at approximately $208 million. This market is projected to grow significantly, reaching an estimated $374.5 million by 2030, with a compound annual growth rate (CAGR) of 8.7% during the forecast period from 2024 to 2030. This growth is largely driven by the increasing demand for lithium-ion batteries, particularly in China, where government policies heavily focus on the development and production of these batteries. In 2022, China's sales of new energy vehicles reached 6.8 million units, accounting for 63.6% of the global market share. In contrast, Europe had a penetration rate of 19%, while North America lagged behind with only 6%. According to the Ministry of Industry and Information Technology, China's production of lithium-ion batteries reached 750 gigawatt-hours (GWh) in 2022, marking a year-on-year increase of over 130%. This rapid growth in production capacity highlights the significant role that China plays in the global lithium battery market. As the demand for lithium batteries continues to rise, the adoption of industrial robotics in this sector is expected to increase, contributing to the efficiency and competitiveness of battery manufacturers worldwide.

| Report Metric | Details |

| Report Name | Industrial Robotics in Lithium Battery - Market |

| Forecasted market size in 2030 | US$ 374.5 million |

| CAGR | 8.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Inovance Technology, Estun Automation, IPLUSMOBOT, CASUN, Hikrobot, Zhejiang HuaRay Technology, Standard Robots, YOUIBOT |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |