What is HSC Machining Center - Global Market?

The HSC (High-Speed Cutting) Machining Center is a pivotal component in the global manufacturing landscape, known for its precision and efficiency in cutting and shaping materials. These centers are designed to operate at high speeds, allowing for rapid production cycles and enhanced accuracy in creating complex parts. The global market for HSC Machining Centers is driven by the increasing demand for high-precision components across various industries, including aerospace, automotive, and medical sectors. These industries require components that meet stringent quality standards, and HSC Machining Centers are equipped to deliver such precision. The market is characterized by technological advancements that enhance the capabilities of these machines, such as improved software for better control and automation features that reduce human intervention. As industries continue to evolve and demand more intricate and precise components, the role of HSC Machining Centers becomes increasingly significant. The global market is also influenced by the need for cost-effective manufacturing solutions, which these centers provide by reducing material waste and energy consumption. Overall, the HSC Machining Center market is poised for growth as it continues to meet the evolving needs of modern manufacturing.

Vertical, Horizontal in the HSC Machining Center - Global Market:

In the realm of HSC Machining Centers, the distinction between vertical and horizontal configurations plays a crucial role in determining their application and efficiency. Vertical HSC Machining Centers are characterized by their vertical spindle orientation, which makes them ideal for operations that require precision and accessibility to the workpiece. These machines are particularly suited for tasks such as die sinking, mold making, and intricate part manufacturing where the workpiece needs to be easily accessible from above. The vertical design allows for better visibility and ease of setup, making it a preferred choice for industries that require high precision and flexibility. On the other hand, Horizontal HSC Machining Centers are designed with a horizontal spindle orientation, which is advantageous for operations that involve heavy and large workpieces. The horizontal configuration allows for better chip evacuation, which is crucial in high-speed machining processes to maintain the quality of the finished product. This design is particularly beneficial in industries such as automotive and aerospace, where large components are common. The horizontal setup also enables the use of multiple fixtures, allowing for simultaneous machining of different parts, thereby increasing productivity. Both vertical and horizontal HSC Machining Centers are equipped with advanced features such as high-speed spindles, precision control systems, and automation capabilities that enhance their performance. The choice between vertical and horizontal configurations depends largely on the specific requirements of the manufacturing process, including the size and complexity of the workpiece, the desired level of precision, and the production volume. As the global market for HSC Machining Centers continues to grow, manufacturers are increasingly focusing on developing machines that offer greater flexibility, efficiency, and precision to meet the diverse needs of various industries. The ongoing advancements in technology, such as the integration of artificial intelligence and machine learning, are further enhancing the capabilities of these machines, making them more adaptable to the changing demands of the manufacturing sector. In conclusion, the choice between vertical and horizontal HSC Machining Centers is influenced by a variety of factors, including the nature of the workpiece, the required precision, and the production environment. Both configurations offer unique advantages that cater to different aspects of the manufacturing process, and their continued evolution is set to drive the growth of the global HSC Machining Center market.

Aerospace & Defense, Automotive, Medical, Others in the HSC Machining Center - Global Market:

The usage of HSC Machining Centers in various industries highlights their versatility and importance in modern manufacturing. In the aerospace and defense sector, these machines are indispensable due to their ability to produce high-precision components that meet stringent safety and quality standards. The aerospace industry, in particular, demands components that are lightweight yet strong, and HSC Machining Centers are capable of machining advanced materials such as titanium and composites with high accuracy. This capability is crucial for the production of aircraft parts, including turbine blades, structural components, and intricate assemblies. In the defense sector, the precision and reliability of HSC Machining Centers are essential for manufacturing components used in military equipment and vehicles, where failure is not an option. In the automotive industry, HSC Machining Centers play a vital role in producing components that require high precision and consistency. The automotive sector is characterized by mass production, and these machines are capable of delivering the speed and accuracy needed to meet the demands of this industry. From engine components to transmission parts, HSC Machining Centers ensure that each part meets the exact specifications required for optimal performance. The medical industry also benefits significantly from the capabilities of HSC Machining Centers. The production of medical devices and implants requires a high degree of precision and quality, as these components often have direct implications on patient safety and health. HSC Machining Centers are used to manufacture complex medical devices, surgical instruments, and implants with the precision necessary to meet regulatory standards. Additionally, the ability to machine biocompatible materials with high accuracy is a significant advantage in this sector. Beyond these industries, HSC Machining Centers find applications in various other sectors, including electronics, energy, and consumer goods. In the electronics industry, the demand for miniaturized and precise components is met by the capabilities of these machines. In the energy sector, they are used to produce components for renewable energy systems, such as wind turbines and solar panels, where precision and durability are critical. The consumer goods industry also benefits from the efficiency and precision of HSC Machining Centers in producing high-quality products. Overall, the versatility and precision of HSC Machining Centers make them an essential tool in a wide range of industries, driving innovation and efficiency in modern manufacturing.

HSC Machining Center - Global Market Outlook:

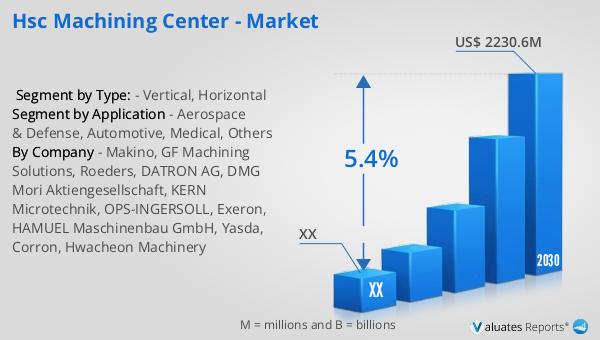

The global market for HSC Machining Centers was valued at approximately $1,532 million in 2023, with projections indicating a growth to around $2,230.6 million by 2030. This growth represents a compound annual growth rate (CAGR) of 5.4% over the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for high-speed, precision machining solutions across various industries. The North American market, in particular, is expected to see significant growth, although specific figures were not provided. The anticipated growth in this region underscores the importance of technological advancements and the adoption of innovative manufacturing processes. The market's expansion is driven by the need for efficient and precise machining solutions that can meet the evolving demands of industries such as aerospace, automotive, and medical. As these industries continue to grow and require more complex and precise components, the demand for HSC Machining Centers is expected to rise. The market outlook suggests a positive trajectory for the HSC Machining Center industry, with opportunities for growth and innovation as manufacturers strive to meet the needs of modern manufacturing. The focus on improving efficiency, reducing costs, and enhancing precision will continue to drive the development and adoption of HSC Machining Centers globally.

| Report Metric | Details |

| Report Name | HSC Machining Center - Market |

| Forecasted market size in 2030 | US$ 2230.6 million |

| CAGR | 5.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Makino, GF Machining Solutions, Roeders, DATRON AG, DMG Mori Aktiengesellschaft, KERN Microtechnik, OPS-INGERSOLL, Exeron, HAMUEL Maschinenbau GmbH, Yasda, Corron, Hwacheon Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |