What is Shell and Tube Graphite Block Heat Exchangers - Global Market?

Shell and tube graphite block heat exchangers are specialized devices used in various industries to transfer heat between two fluids. These exchangers consist of a series of graphite blocks arranged in a shell and tube configuration, which allows for efficient heat transfer while maintaining the integrity of the fluids involved. Graphite is chosen for its excellent thermal conductivity and resistance to corrosion, making it ideal for handling aggressive chemicals and high-temperature applications. The global market for these heat exchangers is driven by their increasing demand in industries such as chemical processing, pharmaceuticals, and food production, where precise temperature control is crucial. As industries continue to seek energy-efficient and durable solutions, the adoption of shell and tube graphite block heat exchangers is expected to grow. These exchangers are particularly valued for their ability to withstand harsh operating conditions and their long service life, which reduces maintenance costs and downtime. The market is characterized by technological advancements aimed at improving the performance and efficiency of these heat exchangers, as well as expanding their application range. As a result, the global market for shell and tube graphite block heat exchangers is poised for significant growth in the coming years.

Fixed Type, Floating Head Type in the Shell and Tube Graphite Block Heat Exchangers - Global Market:

In the realm of shell and tube graphite block heat exchangers, two primary types are prevalent: the fixed type and the floating head type. The fixed type heat exchanger is designed with tubes that are permanently attached to the shell, providing a robust and leak-proof structure. This design is particularly advantageous in applications where the temperature and pressure conditions are stable, as it minimizes the risk of fluid leakage and ensures consistent performance. However, the fixed nature of the tubes can pose challenges during maintenance and cleaning, as the entire unit may need to be disassembled to access the internal components. Despite this, the fixed type remains a popular choice in industries where reliability and durability are paramount. On the other hand, the floating head type heat exchanger offers greater flexibility and ease of maintenance. In this design, one end of the tube bundle is free to move, allowing for thermal expansion and contraction without causing stress on the tubes. This feature is particularly beneficial in applications where temperature fluctuations are common, as it reduces the risk of tube damage and extends the lifespan of the exchanger. Additionally, the floating head design facilitates easier cleaning and maintenance, as the tube bundle can be removed without dismantling the entire unit. This makes it an attractive option for industries that require frequent maintenance or operate under variable conditions. Both types of heat exchangers are integral to the global market, catering to diverse industrial needs and preferences. The choice between fixed and floating head types often depends on specific operational requirements, such as temperature range, pressure conditions, and maintenance considerations. As industries continue to evolve and demand more efficient heat transfer solutions, manufacturers are focusing on enhancing the design and performance of both fixed and floating head heat exchangers. Innovations in materials and manufacturing processes are being explored to improve the thermal efficiency, corrosion resistance, and overall durability of these exchangers. Furthermore, the integration of advanced monitoring and control systems is becoming increasingly common, allowing for real-time performance tracking and optimization. This trend is expected to drive the adoption of both fixed and floating head types in various industries, contributing to the growth of the global market for shell and tube graphite block heat exchangers.

Chemical Industry, Food Industry, Pharmacy, Agriculture, Others in the Shell and Tube Graphite Block Heat Exchangers - Global Market:

Shell and tube graphite block heat exchangers find extensive usage across several industries, each benefiting from their unique properties. In the chemical industry, these heat exchangers are indispensable due to their ability to handle corrosive substances and high temperatures. They are used in processes such as acid production, where maintaining precise temperature control is crucial for product quality and safety. The durability and resistance to chemical attack offered by graphite make these exchangers a preferred choice for chemical manufacturers seeking reliable and long-lasting solutions. In the food industry, shell and tube graphite block heat exchangers play a vital role in processes such as pasteurization and sterilization. The ability to efficiently transfer heat while maintaining the integrity of food products is essential for ensuring safety and quality. These exchangers are designed to meet stringent hygiene standards, making them suitable for use in food processing environments. Their resistance to fouling and ease of cleaning further enhance their appeal in this sector. The pharmaceutical industry also relies heavily on shell and tube graphite block heat exchangers for various applications, including the production of active pharmaceutical ingredients (APIs) and the formulation of drugs. Precise temperature control is critical in pharmaceutical processes to ensure the efficacy and stability of products. The non-reactive nature of graphite ensures that there is no contamination of sensitive pharmaceutical compounds, making these exchangers an ideal choice for pharmaceutical manufacturers. In agriculture, these heat exchangers are used in processes such as fertilizer production and the treatment of agricultural waste. The ability to withstand harsh chemicals and high temperatures makes them suitable for handling the demanding conditions often encountered in agricultural applications. Additionally, their efficiency in heat transfer contributes to energy savings and reduced operational costs, which are important considerations for the agricultural sector. Beyond these industries, shell and tube graphite block heat exchangers are also employed in other areas such as power generation, oil and gas, and wastewater treatment. Their versatility and adaptability to different operating conditions make them a valuable asset in a wide range of applications. As industries continue to prioritize energy efficiency and sustainability, the demand for shell and tube graphite block heat exchangers is expected to rise, driving further innovation and development in this field.

Shell and Tube Graphite Block Heat Exchangers - Global Market Outlook:

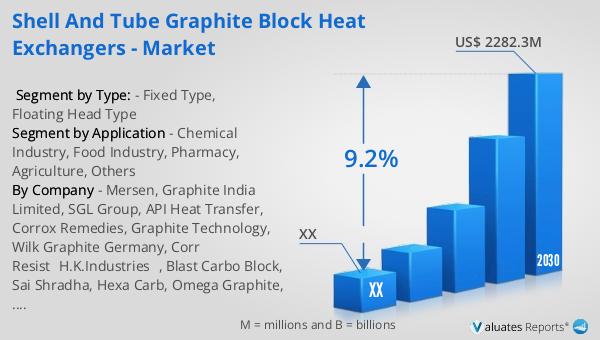

The global market for shell and tube graphite block heat exchangers was valued at approximately US$ 1,218 million in 2023. It is projected to grow significantly, reaching an estimated size of US$ 2,282.3 million by 2030, with a compound annual growth rate (CAGR) of 9.2% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for efficient and durable heat transfer solutions across various industries. In North America, the market for these heat exchangers was valued at a substantial amount in 2023, and it is anticipated to continue its upward trajectory, reaching a higher valuation by 2030. The growth in this region is driven by the expanding industrial base and the need for advanced heat transfer technologies. The CAGR for the North American market during the forecast period is expected to align with the global trend, underscoring the region's significant contribution to the overall market growth. As industries worldwide continue to seek innovative and sustainable solutions, the market for shell and tube graphite block heat exchangers is poised for robust expansion, driven by technological advancements and increasing adoption across diverse sectors.

| Report Metric | Details |

| Report Name | Shell and Tube Graphite Block Heat Exchangers - Market |

| Forecasted market size in 2030 | US$ 2282.3 million |

| CAGR | 9.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mersen, Graphite India Limited, SGL Group, API Heat Transfer, Corrox Remedies, Graphite Technology, Wilk Graphite Germany, Corr Resist(H.K.Industries), Blast Carbo Block, Sai Shradha, Hexa Carb, Omega Graphite, SVI Carbon, Graphicarb, Nantong Xingqiu Graphite, Nantong Sunshine, Nantong Xinbao Graphite Equipment, Qingdao BoHua |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |