What is Global Industrial Slow Shredder Market?

The Global Industrial Slow Shredder Market is a specialized segment within the broader industrial machinery sector, focusing on equipment designed to reduce the size of various materials through slow-speed shredding. These shredders are engineered to handle a wide range of materials, including metals, plastics, wood, and waste, making them essential in industries such as recycling, waste management, and manufacturing. Unlike high-speed shredders, slow shredders operate at lower speeds, which reduces noise and dust generation, making them more environmentally friendly and suitable for indoor operations. The market for these machines is driven by the increasing need for efficient waste management solutions and the growing emphasis on recycling and sustainability. As industries continue to seek ways to minimize their environmental footprint, the demand for slow shredders is expected to rise. These machines not only help in reducing waste volume but also in recovering valuable materials that can be reused or recycled, thereby contributing to a circular economy. The market is characterized by a variety of shredder types, each designed to meet specific industrial needs, and is supported by advancements in technology that enhance their efficiency and effectiveness.

Single Shaft Crusher, Double Shaft Crusher, Four Shaft Crusher in the Global Industrial Slow Shredder Market:

In the realm of the Global Industrial Slow Shredder Market, different types of crushers play pivotal roles, each tailored to specific shredding needs. The Single Shaft Crusher is a versatile machine known for its simplicity and efficiency. It features a single rotating shaft with cutting blades that shred materials against a fixed counter blade. This type of crusher is ideal for processing a variety of materials, including plastics, wood, and light metals. Its design allows for easy maintenance and adjustment, making it a popular choice for industries that require consistent and reliable shredding performance. The Single Shaft Crusher is particularly effective in applications where uniform particle size is crucial, as it can be equipped with screens to control the output size. On the other hand, the Double Shaft Crusher is designed for more demanding applications. It features two parallel shafts equipped with cutting discs that rotate in opposite directions. This configuration allows the crusher to handle larger and tougher materials, such as bulky waste, tires, and industrial scrap. The intermeshing of the cutting discs ensures efficient shredding, even for materials that are difficult to process. The Double Shaft Crusher is known for its robustness and durability, making it suitable for heavy-duty applications where high throughput is required. Its ability to handle a wide range of materials with varying densities and compositions makes it a versatile tool in the industrial shredding landscape. The Four Shaft Crusher takes shredding capabilities to the next level with its complex design and enhanced performance. It consists of four shafts that work in pairs to shred materials into smaller pieces. This type of crusher is particularly effective for applications that require fine shredding and precise particle size control. The Four Shaft Crusher is often used in industries where the material to be shredded is highly heterogeneous, such as electronic waste, mixed scrap, and complex industrial waste streams. Its design allows for the separation of different material components during the shredding process, facilitating recycling and material recovery. The Four Shaft Crusher is equipped with advanced features such as automatic reverse and overload protection, ensuring safe and efficient operation even under challenging conditions. Each of these crushers plays a crucial role in the Global Industrial Slow Shredder Market, catering to the diverse needs of industries that require efficient and reliable shredding solutions. The choice between Single Shaft, Double Shaft, and Four Shaft Crushers depends on the specific requirements of the application, including the type of material to be shredded, the desired output size, and the throughput capacity. As industries continue to prioritize sustainability and resource efficiency, the demand for these crushers is expected to grow, driving innovation and advancements in shredding technology.

Forestry, Waste Recycling, Mining, Metal Recycling in the Global Industrial Slow Shredder Market:

The Global Industrial Slow Shredder Market finds extensive applications across various sectors, including forestry, waste recycling, mining, and metal recycling, each benefiting from the unique capabilities of slow shredders. In forestry, slow shredders are used to process wood waste, such as branches, logs, and stumps, into smaller, manageable pieces. This not only reduces the volume of waste but also facilitates its conversion into valuable products like mulch, wood chips, and biomass fuel. The ability of slow shredders to handle large and irregularly shaped materials makes them indispensable in forestry operations, where efficient waste management is crucial for maintaining sustainable practices. In the waste recycling sector, slow shredders play a vital role in reducing the size of various waste materials, including plastics, paper, and organic waste. By breaking down these materials into smaller pieces, slow shredders enhance the efficiency of subsequent recycling processes, such as sorting, separation, and material recovery. This contributes to the overall effectiveness of recycling operations, enabling the recovery of valuable resources and reducing the environmental impact of waste disposal. The versatility of slow shredders allows them to handle a wide range of waste types, making them a key component in integrated waste management systems. Mining operations also benefit from the use of slow shredders, particularly in the processing of mineral ores and other raw materials. Slow shredders are used to break down large rocks and boulders into smaller fragments, facilitating their transport and further processing. This not only improves the efficiency of mining operations but also reduces the wear and tear on other equipment, such as crushers and conveyors. The robust design of slow shredders allows them to withstand the harsh conditions of mining environments, ensuring reliable performance even in challenging applications. In the metal recycling industry, slow shredders are used to process scrap metal, such as aluminum, steel, and copper, into smaller pieces that can be easily handled and transported. This is essential for efficient recycling operations, as it enables the separation of different metal types and the recovery of valuable materials. Slow shredders are particularly effective in processing mixed metal scrap, where their ability to handle tough and dense materials ensures high throughput and consistent performance. The use of slow shredders in metal recycling not only enhances the efficiency of recycling processes but also contributes to the conservation of natural resources by enabling the reuse of metals. Overall, the Global Industrial Slow Shredder Market plays a crucial role in supporting sustainable practices across various industries. By providing efficient and reliable shredding solutions, slow shredders help reduce waste, recover valuable resources, and minimize the environmental impact of industrial operations. As industries continue to prioritize sustainability and resource efficiency, the demand for slow shredders is expected to grow, driving further advancements in shredding technology and expanding their applications across different sectors.

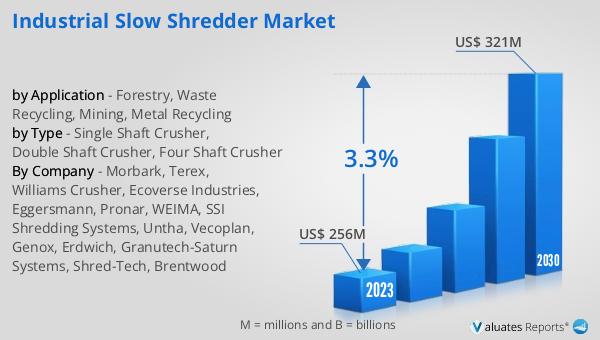

Global Industrial Slow Shredder Market Outlook:

The global market for Industrial Slow Shredders was valued at $256 million in 2023, and it is projected to grow to $321 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.3% over the forecast period from 2024 to 2030. This steady increase in market value highlights the rising demand for slow shredders across various industries. The growth can be attributed to several factors, including the increasing emphasis on sustainable waste management practices and the need for efficient recycling solutions. As industries continue to seek ways to minimize their environmental impact, the adoption of slow shredders is expected to rise, driving market growth. The projected growth of the Industrial Slow Shredder Market also reflects the ongoing advancements in shredding technology, which enhance the efficiency and effectiveness of these machines. Manufacturers are continually developing new features and capabilities to meet the evolving needs of industries, further fueling market expansion. Additionally, the growing awareness of the benefits of slow shredders, such as reduced noise and dust generation, is contributing to their increased adoption in various applications. Overall, the positive market outlook for Industrial Slow Shredders underscores the importance of these machines in supporting sustainable industrial practices. As the market continues to grow, it is expected to drive further innovation and development in shredding technology, expanding the range of applications and benefits offered by slow shredders.

| Report Metric | Details |

| Report Name | Industrial Slow Shredder Market |

| Accounted market size in 2023 | US$ 256 million |

| Forecasted market size in 2030 | US$ 321 million |

| CAGR | 3.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Morbark, Terex, Williams Crusher, Ecoverse Industries, Eggersmann, Pronar, WEIMA, SSI Shredding Systems, Untha, Vecoplan, Genox, Erdwich, Granutech-Saturn Systems, Shred-Tech, Brentwood |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |