What is Automatic Wafer Biscuit Production Machine - Global Market?

The Automatic Wafer Biscuit Production Machine is a sophisticated piece of equipment designed to streamline the process of making wafer biscuits on a large scale. This machine is a crucial component in the food manufacturing industry, particularly for companies that produce wafer biscuits as a significant part of their product line. The global market for these machines is expanding as more manufacturers seek to improve efficiency, reduce labor costs, and increase production capacity. These machines automate various stages of the wafer biscuit production process, from mixing and baking to cooling and packaging, ensuring consistent quality and taste. The demand for automatic wafer biscuit production machines is driven by the growing popularity of wafer biscuits worldwide, as well as the need for manufacturers to meet high consumer expectations for product quality and variety. As technology advances, these machines are becoming more sophisticated, offering features such as programmable controls, energy efficiency, and easy maintenance, which further enhance their appeal to manufacturers. The global market for these machines is expected to continue growing as more companies invest in automation to stay competitive in the food industry.

Wafer Biscuit Production Line, Packaging Machine, Feeding System in the Automatic Wafer Biscuit Production Machine - Global Market:

The Wafer Biscuit Production Line is an integral part of the Automatic Wafer Biscuit Production Machine, encompassing all the necessary equipment to produce wafer biscuits from start to finish. This production line typically includes a batter mixer, a baking oven, a cooling system, a cream spreading machine, and a cutting and packaging unit. Each component of the production line is designed to work seamlessly with the others, ensuring a smooth and efficient production process. The batter mixer combines ingredients to create a consistent batter, which is then poured into the baking oven to form wafer sheets. Once baked, the wafer sheets are cooled and transferred to the cream spreading machine, where a layer of cream is applied. The layered wafers are then cut into the desired shape and size before being packaged for distribution. The Packaging Machine is a critical component of the production line, responsible for ensuring that the finished wafer biscuits are securely and attractively packaged. This machine can handle various packaging materials and formats, allowing manufacturers to choose the best option for their product. The Feeding System is another essential part of the production line, responsible for transporting raw materials and finished products between different stages of the production process. This system is designed to minimize waste and ensure that each component of the production line operates at maximum efficiency. In the global market, the demand for wafer biscuit production lines, packaging machines, and feeding systems is driven by the need for manufacturers to increase production capacity and improve product quality. As consumer preferences continue to evolve, manufacturers are investing in advanced production lines that offer greater flexibility and customization options. This trend is expected to drive further growth in the global market for automatic wafer biscuit production machines.

SMEs, Large Enterprises in the Automatic Wafer Biscuit Production Machine - Global Market:

The usage of Automatic Wafer Biscuit Production Machines varies significantly between Small and Medium-sized Enterprises (SMEs) and Large Enterprises, reflecting their different operational scales and strategic goals. For SMEs, these machines represent a significant investment that can dramatically enhance their production capabilities. By automating the wafer biscuit production process, SMEs can reduce their reliance on manual labor, which not only cuts costs but also minimizes the risk of human error. This automation allows SMEs to produce wafer biscuits more consistently and efficiently, enabling them to compete more effectively with larger companies. Additionally, the flexibility of these machines allows SMEs to experiment with different recipes and product variations, helping them to differentiate their offerings in a crowded market. On the other hand, Large Enterprises benefit from Automatic Wafer Biscuit Production Machines by leveraging their advanced features to maximize production efficiency and output. These enterprises often operate on a much larger scale, requiring machines that can handle high volumes of production without compromising on quality. The sophisticated technology integrated into these machines, such as programmable controls and energy-efficient designs, allows large enterprises to optimize their production processes and reduce operational costs. Furthermore, the ability to produce a wide range of wafer biscuit products quickly and consistently helps large enterprises to meet the diverse demands of their global customer base. In the global market, both SMEs and Large Enterprises are increasingly adopting automatic wafer biscuit production machines to stay competitive and meet the growing demand for high-quality wafer biscuits. As these machines become more advanced and accessible, their usage is expected to continue expanding across different segments of the food manufacturing industry.

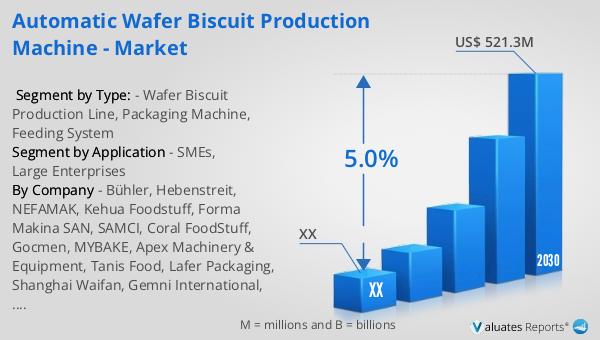

Automatic Wafer Biscuit Production Machine - Global Market Outlook:

The global market for Automatic Wafer Biscuit Production Machines was valued at approximately $370 million in 2023. It is projected to grow to a revised size of $521.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for automation in the food manufacturing industry, driven by the need for efficiency, consistency, and cost-effectiveness. In North America, the market for these machines was valued at a certain amount in 2023 and is expected to reach a new value by 2030, with a specific CAGR during the forecast period. This regional growth highlights the importance of technological advancements and the adoption of automated solutions in maintaining competitiveness in the market. As manufacturers continue to seek ways to improve their production processes and meet consumer demands, the market for automatic wafer biscuit production machines is poised for significant growth. This trend underscores the critical role that these machines play in the global food manufacturing industry, as companies strive to enhance their production capabilities and deliver high-quality products to consumers worldwide.

| Report Metric | Details |

| Report Name | Automatic Wafer Biscuit Production Machine - Market |

| Forecasted market size in 2030 | US$ 521.3 million |

| CAGR | 5.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Bühler, Hebenstreit, NEFAMAK, Kehua Foodstuff, Forma Makina SAN, SAMCI, Coral FoodStuff, Gocmen, MYBAKE, Apex Machinery & Equipment, Tanis Food, Lafer Packaging, Shanghai Waifan, Gemni International, Ambaji Automations |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |