What is Electronics Structural Adhesives - Global Market?

Electronics structural adhesives are specialized bonding agents used in the assembly and manufacturing of electronic devices. These adhesives are designed to provide strong, durable bonds between various components, ensuring the structural integrity and reliability of electronic products. The global market for electronics structural adhesives is driven by the increasing demand for miniaturized and lightweight electronic devices, which require advanced bonding solutions. These adhesives are used in a wide range of applications, including mobile phones, tablets, monitors, televisions, and laptops, among others. They offer several advantages, such as excellent adhesion to different substrates, resistance to environmental factors, and the ability to withstand thermal and mechanical stresses. As the electronics industry continues to evolve, the demand for high-performance structural adhesives is expected to grow, driven by technological advancements and the need for more efficient and reliable electronic devices. The market is characterized by a diverse range of adhesive types, including acrylate-based, epoxy-based, and other formulations, each offering unique properties and benefits for specific applications.

Acrylate Based, Epoxy Based, Others in the Electronics Structural Adhesives - Global Market:

Acrylate-based adhesives are a popular choice in the electronics structural adhesives market due to their excellent bonding properties and versatility. These adhesives are known for their fast curing times, which make them ideal for high-speed manufacturing processes. Acrylate-based adhesives offer strong adhesion to a variety of substrates, including metals, plastics, and glass, making them suitable for a wide range of electronic applications. They are also resistant to environmental factors such as moisture, UV light, and temperature fluctuations, ensuring the longevity and reliability of electronic devices. Additionally, acrylate-based adhesives are often used in applications where flexibility and impact resistance are important, such as in mobile phones and tablets. Epoxy-based adhesives, on the other hand, are renowned for their exceptional strength and durability. These adhesives form strong, rigid bonds that can withstand significant mechanical stresses, making them ideal for applications where structural integrity is critical. Epoxy-based adhesives are commonly used in the assembly of monitors, televisions, and laptops, where they provide excellent adhesion to metal and plastic components. They also offer good thermal and chemical resistance, which is essential for electronic devices that are exposed to harsh operating conditions. Other types of adhesives used in the electronics structural adhesives market include silicone-based and polyurethane-based formulations. Silicone-based adhesives are valued for their flexibility and ability to maintain their properties over a wide temperature range. They are often used in applications where thermal management is important, such as in heat sinks and LED assemblies. Polyurethane-based adhesives, meanwhile, offer a good balance of strength and flexibility, making them suitable for applications that require both structural support and impact resistance. These adhesives are commonly used in the assembly of electronic components that are subject to vibration and shock, such as automotive electronics and industrial equipment. Overall, the choice of adhesive depends on the specific requirements of the application, including the materials being bonded, the operating environment, and the desired performance characteristics.

Mobile Phones, Tablets, Monitors, Televisions, Laptops, Others in the Electronics Structural Adhesives - Global Market:

Electronics structural adhesives play a crucial role in the assembly and manufacturing of various electronic devices, including mobile phones, tablets, monitors, televisions, laptops, and other electronic products. In mobile phones, these adhesives are used to bond components such as the display, battery, and internal circuitry, ensuring the device's structural integrity and reliability. The adhesives provide strong, durable bonds that can withstand the mechanical stresses and environmental factors that mobile phones are exposed to, such as drops, impacts, and temperature fluctuations. In tablets, electronics structural adhesives are used to assemble the display, touch screen, and internal components, providing a secure and reliable bond that enhances the device's performance and durability. The adhesives also help to reduce the weight and thickness of tablets, contributing to the trend towards lighter and more portable devices. In monitors and televisions, electronics structural adhesives are used to bond the display panel to the frame and other components, ensuring a secure and stable assembly. These adhesives provide excellent adhesion to glass and metal substrates, which are commonly used in the construction of monitors and televisions. They also offer good thermal and chemical resistance, which is important for devices that generate heat during operation. In laptops, electronics structural adhesives are used to bond components such as the display, keyboard, and internal circuitry, providing a strong and durable assembly that can withstand the rigors of daily use. The adhesives also help to reduce the weight and thickness of laptops, making them more portable and convenient for users. In addition to these applications, electronics structural adhesives are used in a wide range of other electronic products, including wearables, gaming consoles, and automotive electronics. These adhesives provide the necessary strength and durability to ensure the reliable performance of electronic devices in various operating conditions. Overall, the use of electronics structural adhesives in these applications is driven by the need for lightweight, durable, and reliable electronic devices that can meet the demands of modern consumers.

Electronics Structural Adhesives - Global Market Outlook:

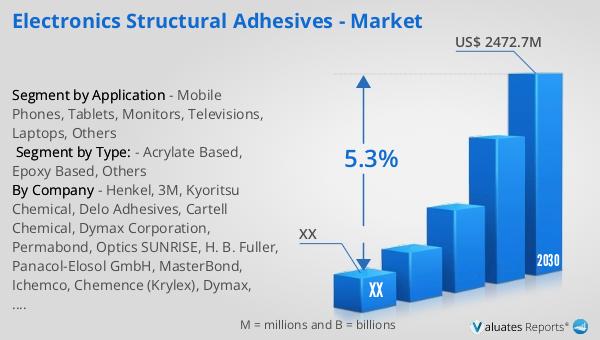

The global market for electronics structural adhesives was valued at approximately $1,731.3 million in 2023, and it is projected to grow to a revised size of $2,472.7 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. In North America, the market for electronics structural adhesives was valued at a certain amount in 2023, and it is anticipated to reach a different value by 2030, with a specific CAGR during the same forecast period. This growth reflects the increasing demand for advanced bonding solutions in the electronics industry, driven by the need for miniaturized and lightweight electronic devices. The market is characterized by a diverse range of adhesive types, including acrylate-based, epoxy-based, and other formulations, each offering unique properties and benefits for specific applications. As the electronics industry continues to evolve, the demand for high-performance structural adhesives is expected to grow, driven by technological advancements and the need for more efficient and reliable electronic devices. The market outlook highlights the importance of these adhesives in ensuring the structural integrity and reliability of electronic products, which are essential for meeting the demands of modern consumers.

| Report Metric | Details |

| Report Name | Electronics Structural Adhesives - Market |

| Forecasted market size in 2030 | US$ 2472.7 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, 3M, Kyoritsu Chemical, Delo Adhesives, Cartell Chemical, Dymax Corporation, Permabond, Optics SUNRISE, H. B. Fuller, Panacol-Elosol GmbH, MasterBond, Ichemco, Chemence (Krylex), Dymax, Parson Adhesives, Loxeal, Novachem, Dexerials, Vibra-Tite, Action Adhesive |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |