What is Electronics SMT Adhesives - Global Market?

Electronics Surface Mount Technology (SMT) adhesives are specialized materials used in the electronics industry to attach components to printed circuit boards (PCBs). These adhesives play a crucial role in ensuring the stability and reliability of electronic devices by providing mechanical support and electrical insulation. The global market for Electronics SMT Adhesives is driven by the increasing demand for miniaturized and high-performance electronic devices. As technology advances, the need for smaller, more efficient components grows, leading to a higher demand for SMT adhesives. These adhesives are designed to withstand various environmental conditions, such as temperature fluctuations and humidity, ensuring the longevity and performance of electronic devices. The market is characterized by a wide range of adhesive types, each offering unique properties tailored to specific applications. Manufacturers are continually innovating to develop adhesives that meet the evolving needs of the electronics industry, focusing on improving thermal conductivity, electrical insulation, and adhesion strength. The global market for Electronics SMT Adhesives is poised for growth as the demand for advanced electronic devices continues to rise, driven by technological advancements and consumer preferences for compact and efficient gadgets.

Acrylic-Based, Cyanoacrylate-Based, Epoxy-Based, Silicone-Based, Polyurethane-Based in the Electronics SMT Adhesives - Global Market:

In the realm of Electronics SMT Adhesives, various types of adhesives are utilized, each with distinct properties and applications. Acrylic-based adhesives are known for their excellent adhesion to a wide range of substrates, including metals and plastics. They offer good resistance to environmental factors such as UV light and moisture, making them suitable for outdoor applications. Acrylic adhesives are often used in applications where flexibility and durability are required, providing a strong bond that can withstand thermal cycling and mechanical stress. Cyanoacrylate-based adhesives, commonly known as super glues, are prized for their rapid curing time and strong bonding capabilities. These adhesives are ideal for applications requiring quick assembly and are often used in situations where a fast-setting adhesive is needed. However, they may not be suitable for high-temperature applications due to their limited thermal resistance. Epoxy-based adhesives are renowned for their exceptional strength and durability. They offer excellent resistance to chemicals, heat, and moisture, making them ideal for harsh environments. Epoxy adhesives are often used in applications where a strong, permanent bond is required, such as in the assembly of heavy-duty electronic components. Silicone-based adhesives are valued for their flexibility and resistance to extreme temperatures. They provide excellent electrical insulation and are often used in applications where thermal management is critical. Silicone adhesives are ideal for bonding components that experience significant thermal expansion and contraction. Polyurethane-based adhesives offer a balance of flexibility and strength, making them suitable for a variety of applications. They provide good resistance to impact and vibration, making them ideal for use in portable electronic devices. Polyurethane adhesives are often used in applications where a flexible bond is required, such as in the assembly of wearable electronics. Each type of adhesive offers unique benefits, and the choice of adhesive depends on the specific requirements of the application, including factors such as substrate compatibility, environmental conditions, and performance expectations. As the electronics industry continues to evolve, the demand for specialized SMT adhesives is expected to grow, driven by the need for reliable and efficient bonding solutions.

Mobile Phones, Tablets, Monitors, Televisions, Laptops, Others in the Electronics SMT Adhesives - Global Market:

Electronics SMT Adhesives find extensive usage in various consumer electronics, including mobile phones, tablets, monitors, televisions, laptops, and other devices. In mobile phones, these adhesives are crucial for securing components such as screens, batteries, and circuit boards, ensuring the device's structural integrity and performance. As mobile phones become more compact and feature-rich, the demand for high-performance adhesives that can withstand thermal and mechanical stresses increases. In tablets, SMT adhesives are used to bond components such as touchscreens, sensors, and internal circuitry. The adhesives must provide a strong bond while allowing for flexibility to accommodate the device's slim design and frequent handling. Monitors and televisions also rely on SMT adhesives to secure components such as display panels, backlights, and circuit boards. These adhesives must offer excellent thermal management and electrical insulation to ensure optimal performance and longevity. In laptops, SMT adhesives are used to bond components such as keyboards, touchpads, and internal circuitry. The adhesives must provide a strong bond while allowing for flexibility to accommodate the device's portable nature and frequent use. Other electronic devices, such as wearable technology and smart home devices, also utilize SMT adhesives to ensure reliable performance and durability. The adhesives must offer excellent adhesion to a variety of substrates, including metals, plastics, and glass, while providing resistance to environmental factors such as temperature fluctuations and moisture. As consumer electronics continue to evolve, the demand for advanced SMT adhesives is expected to grow, driven by the need for reliable and efficient bonding solutions that can meet the demands of modern electronic devices.

Electronics SMT Adhesives - Global Market Outlook:

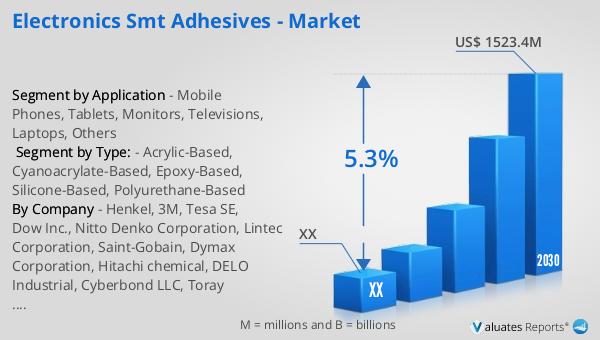

The global market for Electronics SMT Adhesives was valued at approximately $1,066.6 million in 2023. It is projected to grow to a revised size of around $1,523.4 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced electronic devices and the corresponding need for reliable adhesive solutions. The North American market for Electronics SMT Adhesives also shows promising growth potential, although specific figures for this region were not provided. The market is expected to expand at a steady pace, driven by technological advancements and the growing adoption of electronic devices in various sectors. The demand for SMT adhesives in North America is likely to be influenced by factors such as the increasing use of miniaturized components, the need for improved thermal management, and the rising popularity of wearable technology and smart home devices. As the market continues to evolve, manufacturers are expected to focus on developing innovative adhesive solutions that meet the specific needs of the electronics industry, ensuring reliable performance and durability in a wide range of applications.

| Report Metric | Details |

| Report Name | Electronics SMT Adhesives - Market |

| Forecasted market size in 2030 | US$ 1523.4 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, 3M, Tesa SE, Dow Inc., Nitto Denko Corporation, Lintec Corporation, Saint-Gobain, Dymax Corporation, Hitachi chemical, DELO Industrial, Cyberbond LLC, Toray Industries, ITW, H.B. Fuller, Hexion, Mitsubishi Chemical, Shinetsu, Daikin, Panacol-Elosol GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |