What is Electric Manipulators - Global Market?

Electric manipulators are advanced devices used to handle and manipulate objects with precision and control. These devices are powered by electricity and are designed to perform tasks that require a high degree of accuracy and repeatability. The global market for electric manipulators is witnessing significant growth due to the increasing demand for automation and precision in various industries. These manipulators are used in a wide range of applications, including manufacturing, assembly, and material handling. They are particularly useful in environments where human intervention is limited or where tasks are too dangerous or repetitive for human workers. The market is driven by technological advancements, increasing industrial automation, and the need for efficient and safe handling of materials. Electric manipulators are available in various configurations and can be customized to meet specific application requirements. They offer several advantages, including improved productivity, reduced labor costs, and enhanced safety. As industries continue to adopt automation technologies, the demand for electric manipulators is expected to grow, making them an integral part of modern industrial processes.

Point Control Electric Manipulators, Continuous Trajectory Control Electric Manipulators in the Electric Manipulators - Global Market:

Point control electric manipulators and continuous trajectory control electric manipulators are two primary types of electric manipulators that serve different purposes in the global market. Point control electric manipulators are designed to move objects from one point to another with precision. They are typically used in applications where the task involves picking up an object from a specific location and placing it at another predetermined location. These manipulators are highly efficient in tasks that require repetitive and precise movements, such as assembly line operations and packaging. They are equipped with sensors and control systems that ensure accurate positioning and movement, making them ideal for tasks that require high precision. On the other hand, continuous trajectory control electric manipulators are designed to follow a continuous path or trajectory. These manipulators are used in applications where the task involves moving an object along a specific path, such as welding, painting, or cutting. They are equipped with advanced control systems that allow them to follow complex paths with high accuracy. Continuous trajectory control manipulators are essential in industries where precision and consistency are critical, such as automotive and aerospace manufacturing. Both types of manipulators offer significant advantages in terms of efficiency, accuracy, and safety. They reduce the need for manual labor, minimize errors, and enhance productivity. The choice between point control and continuous trajectory control manipulators depends on the specific requirements of the application. In the global market, the demand for both types of manipulators is increasing as industries continue to automate their processes and seek solutions that offer precision and efficiency. The advancements in technology have also led to the development of more sophisticated and versatile manipulators that can handle a wide range of tasks. As a result, electric manipulators are becoming an essential component of modern industrial operations, providing businesses with the tools they need to remain competitive in a rapidly changing market.

Machinery, Metallurgical, Electronic, Light Industry, Atomic Energy in the Electric Manipulators - Global Market:

Electric manipulators are widely used across various industries, including machinery, metallurgical, electronic, light industry, and atomic energy, due to their versatility and precision. In the machinery industry, electric manipulators are used for tasks such as assembly, welding, and material handling. They help improve efficiency and accuracy in manufacturing processes, reducing the need for manual labor and minimizing errors. In the metallurgical industry, electric manipulators are used for handling heavy and hot materials, such as molten metal and steel. They provide a safe and efficient way to move materials in environments that are hazardous for human workers. In the electronic industry, electric manipulators are used for assembling delicate components and handling sensitive materials. They offer the precision and control needed to work with small and intricate parts, ensuring high-quality products. In the light industry, electric manipulators are used for tasks such as packaging, sorting, and quality control. They help streamline operations and improve productivity by automating repetitive tasks. In the atomic energy industry, electric manipulators are used for handling radioactive materials and performing tasks in environments with high radiation levels. They provide a safe and reliable way to perform tasks that would be dangerous for human workers. Overall, electric manipulators play a crucial role in enhancing efficiency, safety, and productivity across various industries. Their ability to perform precise and repetitive tasks makes them an invaluable tool in modern industrial operations. As industries continue to adopt automation technologies, the demand for electric manipulators is expected to grow, further driving their adoption in various applications.

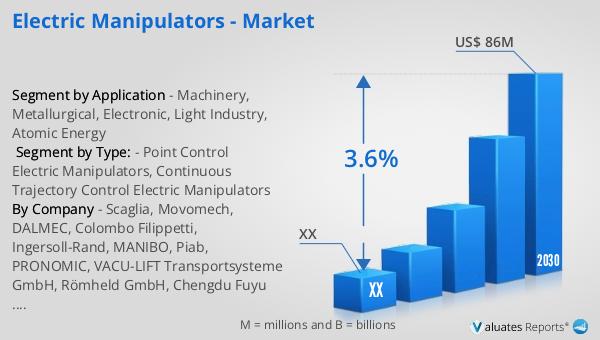

Electric Manipulators - Global Market Outlook:

In 2023, the global market for electric manipulators was valued at approximately $68 million. This market is projected to expand to a revised size of $86 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.6% over the forecast period from 2024 to 2030. The North American segment of the electric manipulators market was also valued at a significant amount in 2023, with expectations to reach a higher value by 2030, maintaining a steady CAGR throughout the forecast period. This growth is indicative of the increasing demand for automation and precision in various industries across the globe. The market's expansion is driven by technological advancements and the need for efficient and safe handling of materials in industrial processes. As industries continue to embrace automation technologies, the demand for electric manipulators is expected to rise, contributing to the market's growth. The projected growth in the market underscores the importance of electric manipulators in modern industrial operations, providing businesses with the tools they need to enhance productivity and remain competitive in a rapidly evolving market landscape.

| Report Metric | Details |

| Report Name | Electric Manipulators - Market |

| Forecasted market size in 2030 | US$ 86 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Scaglia, Movomech, DALMEC, Colombo Filippetti, Ingersoll-Rand, MANIBO, Piab, PRONOMIC, VACU-LIFT Transportsysteme GmbH, Römheld GmbH, Chengdu Fuyu Technology, Whitech srl, Ross, MR Motion Control, Camerobot, PhotoRobot, Electric Friends, Hanson Creative, FAMATEC, Cimlec Industrie, Servolift GmbH, VINKO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |