What is Dental Dry Milling Machine - Global Market?

Dental dry milling machines are specialized equipment used in the dental industry to create precise dental restorations such as crowns, bridges, and dentures. These machines operate without the use of coolants or lubricants, which is why they are referred to as "dry" milling machines. The global market for dental dry milling machines is expanding due to the increasing demand for advanced dental care solutions and the growing awareness of oral health. These machines offer high precision and efficiency, making them a preferred choice for dental laboratories and clinics. They are capable of milling a variety of materials, including metals and ceramics, which are commonly used in dental restorations. The market is driven by technological advancements, the rising prevalence of dental disorders, and the increasing adoption of digital dentistry. As more dental professionals seek to improve the quality and speed of their services, the demand for dental dry milling machines is expected to continue growing. The machines' ability to produce high-quality dental prosthetics with minimal waste and reduced production time makes them an attractive investment for dental practices worldwide.

4 Axis, 5 Axis in the Dental Dry Milling Machine - Global Market:

In the realm of dental dry milling machines, the distinction between 4-axis and 5-axis machines is crucial for understanding their capabilities and applications. A 4-axis dental dry milling machine operates with four degrees of freedom, allowing it to move and rotate the milling tool along four different axes. This configuration is suitable for producing relatively simple dental restorations, such as crowns and small bridges, where the complexity of the design does not require extensive maneuverability. The 4-axis machines are generally more affordable and easier to operate, making them an ideal choice for smaller dental laboratories or clinics that focus on standard dental procedures. They offer a good balance between cost and functionality, providing reliable performance for routine dental milling tasks. On the other hand, 5-axis dental dry milling machines offer an additional degree of freedom, allowing the milling tool to move along five different axes. This added flexibility enables the machine to create more complex and intricate dental restorations, such as full-arch bridges and implant-supported prosthetics. The 5-axis machines are capable of milling undercuts and other challenging geometries that are difficult to achieve with 4-axis machines. This makes them particularly valuable for dental laboratories that handle a wide range of dental cases, including those that require customized and highly detailed restorations. The advanced capabilities of 5-axis machines come with a higher price tag and a steeper learning curve, but they offer significant advantages in terms of precision and versatility. As the demand for personalized dental solutions continues to rise, the adoption of 5-axis dental dry milling machines is expected to increase, especially in larger dental laboratories and specialized clinics. Both 4-axis and 5-axis machines play a vital role in the dental industry, catering to different needs and budgets. While 4-axis machines provide a cost-effective solution for standard dental milling tasks, 5-axis machines offer the advanced capabilities required for complex and customized restorations. The choice between the two depends on the specific requirements of the dental practice, the complexity of the cases they handle, and their budgetary constraints. As technology continues to evolve, both types of machines are likely to see improvements in terms of speed, accuracy, and ease of use, further enhancing their appeal to dental professionals worldwide.

Dental Metallic Material, Dental Ceramic Material, Other in the Dental Dry Milling Machine - Global Market:

Dental dry milling machines are utilized in various areas of dental material processing, including dental metallic materials, dental ceramic materials, and other materials. In the context of dental metallic materials, these machines are used to mill metals such as titanium and cobalt-chromium, which are commonly used in dental implants and frameworks. The precision and accuracy of dental dry milling machines ensure that the metallic components fit perfectly, providing a strong and durable foundation for dental restorations. The ability to mill metals without the need for coolants or lubricants reduces the risk of contamination and ensures a clean and efficient milling process. In the realm of dental ceramic materials, dental dry milling machines are employed to create restorations from materials like zirconia and lithium disilicate. These ceramics are favored for their aesthetic qualities, as they closely mimic the appearance of natural teeth. The high precision of dry milling machines allows for the creation of intricate designs and detailed surface textures, resulting in restorations that are both functional and visually appealing. The dry milling process also minimizes the risk of moisture-related issues, which can affect the integrity of ceramic materials. Beyond metallic and ceramic materials, dental dry milling machines are also used to process other materials such as composite resins and PMMA (polymethyl methacrylate). These materials are often used for temporary restorations, dental models, and other applications where flexibility and ease of use are important. The versatility of dental dry milling machines makes them suitable for a wide range of dental materials, allowing dental professionals to offer a comprehensive array of services to their patients. The ability to mill different materials with a single machine streamlines the workflow in dental laboratories and clinics, reducing the need for multiple specialized machines and enhancing overall efficiency. As the demand for high-quality dental restorations continues to grow, the use of dental dry milling machines in processing various dental materials is expected to increase, further driving the global market for these advanced machines.

Dental Dry Milling Machine - Global Market Outlook:

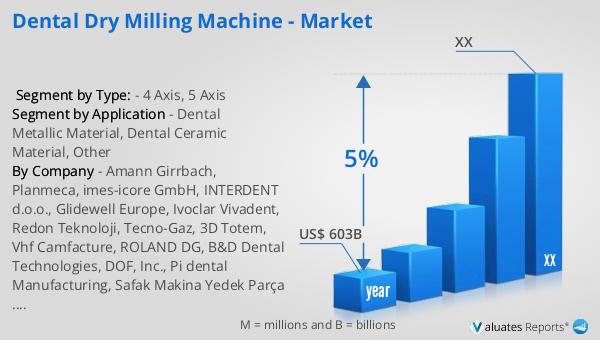

Our research indicates that the global market for medical devices, which includes dental dry milling machines, is projected to reach approximately $603 billion in 2023. This market is anticipated to grow at a compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including technological advancements, increasing healthcare expenditure, and the rising prevalence of chronic diseases that necessitate medical interventions. The dental segment, in particular, is experiencing significant growth due to the increasing demand for advanced dental care solutions and the growing awareness of oral health. Dental dry milling machines, as part of this broader medical device market, are benefiting from these trends. The machines' ability to produce high-quality dental restorations with precision and efficiency makes them an attractive investment for dental professionals. As the market continues to expand, manufacturers are focusing on developing innovative solutions to meet the evolving needs of dental practitioners and patients. The increasing adoption of digital dentistry and the shift towards minimally invasive procedures are also contributing to the growth of the dental dry milling machine market. As more dental professionals seek to improve the quality and speed of their services, the demand for these machines is expected to continue rising, further driving the growth of the global medical device market.

| Report Metric | Details |

| Report Name | Dental Dry Milling Machine - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Amann Girrbach, Planmeca, imes-icore GmbH, INTERDENT d.o.o., Glidewell Europe, Ivoclar Vivadent, Redon Teknoloji, Tecno-Gaz, 3D Totem, Vhf Camfacture, ROLAND DG, B&D Dental Technologies, DOF, Inc., Pi dental Manufacturing, Safak Makina Yedek Parça Sanayi ve Ticaret A.S., DENTAS, Meisinger, Shenzhen Yurucheng Dental Materials Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |