What is Constant Conductance Heat Pipes - Global Market?

Constant Conductance Heat Pipes (CCHPs) are a crucial component in thermal management systems, designed to efficiently transfer heat from one point to another with minimal temperature difference. These devices operate on the principle of phase change, where a working fluid inside the pipe evaporates at the heat source and condenses at the heat sink, effectively transporting heat. The global market for CCHPs is driven by their widespread application across various industries, including electronics, aerospace, and industrial processes. As technology advances and the demand for efficient thermal management solutions grows, the market for CCHPs is expected to expand. These heat pipes are favored for their reliability, efficiency, and ability to operate in a wide range of temperatures, making them indispensable in environments where precise temperature control is critical. The market's growth is also fueled by the increasing miniaturization of electronic devices, which necessitates advanced cooling solutions to prevent overheating and ensure optimal performance. As industries continue to innovate and seek sustainable solutions, CCHPs are poised to play a significant role in meeting these demands, offering a versatile and effective means of heat transfer.

Aluminum, Copper, Stainless steel in the Constant Conductance Heat Pipes - Global Market:

Aluminum, copper, and stainless steel are the primary materials used in the construction of Constant Conductance Heat Pipes, each offering distinct advantages and characteristics that cater to specific applications and requirements. Aluminum-based heat pipes are highly favored for their lightweight nature and excellent thermal conductivity, making them ideal for applications where weight is a critical factor, such as in aerospace and portable electronics. The use of aluminum allows for the creation of heat pipes that are not only efficient but also cost-effective, as aluminum is generally less expensive than other metals. Additionally, aluminum's corrosion resistance enhances the durability and longevity of the heat pipes, ensuring reliable performance over extended periods. Copper, on the other hand, is renowned for its superior thermal conductivity, which is significantly higher than that of aluminum. This makes copper-based heat pipes particularly effective in applications where rapid heat dissipation is essential, such as in high-performance computing and industrial processes. The ability of copper to efficiently transfer heat makes it a preferred choice in scenarios where maintaining optimal operating temperatures is crucial to prevent equipment failure and ensure operational efficiency. However, the higher cost and weight of copper compared to aluminum can be a limiting factor in some applications, particularly where budget constraints or weight limitations are present. Stainless steel heat pipes offer a unique set of advantages, primarily due to their exceptional strength and resistance to corrosion and oxidation. These properties make stainless steel heat pipes suitable for use in harsh environments, such as those encountered in chemical processing and certain aerospace applications. The robustness of stainless steel ensures that the heat pipes can withstand extreme conditions without compromising performance, making them a reliable choice for critical applications. Despite their advantages, stainless steel heat pipes typically have lower thermal conductivity compared to aluminum and copper, which can limit their effectiveness in applications requiring rapid heat transfer. However, their durability and resistance to environmental factors often outweigh this limitation, particularly in applications where longevity and reliability are paramount. The choice of material for CCHPs is largely determined by the specific requirements of the application, including factors such as thermal conductivity, weight, cost, and environmental conditions. As the global market for CCHPs continues to grow, driven by advancements in technology and increasing demand for efficient thermal management solutions, the selection of appropriate materials will remain a key consideration for manufacturers and end-users alike. Each material offers unique benefits that can be leveraged to optimize the performance and efficiency of heat pipes, ensuring that they meet the diverse needs of various industries and applications.

Consumer Electronics, Process Industry, Aerospace in the Constant Conductance Heat Pipes - Global Market:

Constant Conductance Heat Pipes find extensive usage across several key industries, including consumer electronics, process industry, and aerospace, each benefiting from the unique thermal management capabilities these devices offer. In the realm of consumer electronics, CCHPs are integral to the design of modern devices, where managing heat effectively is crucial to maintaining performance and extending the lifespan of components. As electronic devices become increasingly compact and powerful, the challenge of dissipating heat efficiently becomes more pronounced. CCHPs provide an effective solution by facilitating rapid heat transfer away from sensitive components, thereby preventing overheating and ensuring that devices operate within safe temperature ranges. This is particularly important in devices such as laptops, smartphones, and gaming consoles, where performance and reliability are directly linked to effective thermal management. In the process industry, CCHPs play a vital role in maintaining optimal operating conditions for various industrial processes. These heat pipes are used to manage heat in systems where precise temperature control is essential, such as in chemical processing, power generation, and manufacturing. By efficiently transferring heat, CCHPs help to maintain stable temperatures, which is critical for ensuring product quality, process efficiency, and equipment longevity. The ability to operate effectively in a wide range of temperatures makes CCHPs a versatile solution for the diverse thermal management needs of the process industry. In the aerospace sector, the use of CCHPs is driven by the need for lightweight, reliable, and efficient thermal management solutions that can withstand the harsh conditions encountered in space and aviation applications. CCHPs are used to regulate temperatures in various aerospace components, including avionics, satellite systems, and propulsion systems. The ability of these heat pipes to operate effectively in microgravity environments and extreme temperatures makes them indispensable in aerospace applications, where maintaining optimal thermal conditions is critical to mission success and safety. The versatility and efficiency of CCHPs make them a preferred choice for aerospace engineers seeking to optimize the performance and reliability of their systems. Across these industries, the adoption of CCHPs is driven by the need for advanced thermal management solutions that can meet the demands of modern technology and industrial processes. As the global market for CCHPs continues to expand, driven by technological advancements and increasing demand for efficient heat transfer solutions, their usage in consumer electronics, process industry, and aerospace is expected to grow, offering significant benefits in terms of performance, reliability, and efficiency.

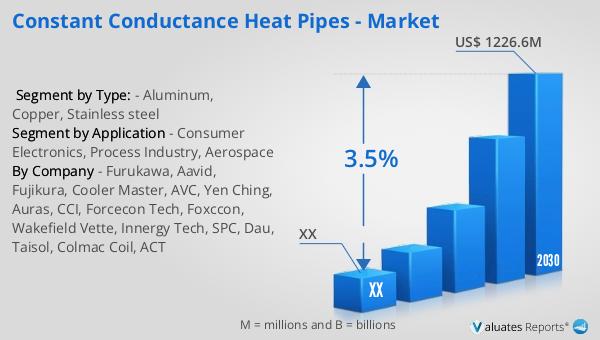

Constant Conductance Heat Pipes - Global Market Outlook:

In 2023, the global market for Constant Conductance Heat Pipes was valued at approximately $967.4 million. Projections indicate that by 2030, this market will expand to an estimated $1,226.6 million, reflecting a compound annual growth rate (CAGR) of 3.5% over the forecast period from 2024 to 2030. This growth trajectory underscores the increasing demand for efficient thermal management solutions across various industries. The North American segment of this market also shows promising potential, although specific figures for 2023 and 2030 are not provided. However, it is anticipated that the region will experience a steady growth rate during the same forecast period. The rising adoption of advanced technologies and the need for effective heat dissipation solutions in sectors such as electronics, aerospace, and industrial processes are key drivers of this market expansion. As industries continue to innovate and prioritize energy efficiency and sustainability, the demand for Constant Conductance Heat Pipes is expected to rise, contributing to the overall growth of the market. The market outlook highlights the importance of these heat pipes in addressing the thermal management challenges faced by modern industries, positioning them as a critical component in the pursuit of enhanced performance and reliability.

| Report Metric | Details |

| Report Name | Constant Conductance Heat Pipes - Market |

| Forecasted market size in 2030 | US$ 1226.6 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Furukawa, Aavid, Fujikura, Cooler Master, AVC, Yen Ching, Auras, CCI, Forcecon Tech, Foxccon, Wakefield Vette, Innergy Tech, SPC, Dau, Taisol, Colmac Coil, ACT |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |