What is Centrifugal Dental Casting Machine - Global Market?

Centrifugal dental casting machines are specialized devices used in the dental industry to create precise dental prosthetics, such as crowns, bridges, and dentures. These machines operate by using centrifugal force to cast molten metal into a mold, ensuring that the metal fills every intricate detail of the mold cavity. This process is crucial for producing high-quality dental restorations that fit perfectly and function effectively in a patient's mouth. The global market for centrifugal dental casting machines is driven by the increasing demand for dental prosthetics, advancements in dental technology, and the growing awareness of oral health. As dental professionals strive to provide better and more efficient services, the adoption of these machines is expected to rise. Additionally, the market is influenced by factors such as the aging population, which requires more dental care, and the increasing prevalence of dental diseases. Manufacturers are focusing on developing machines that are more user-friendly, efficient, and capable of producing high-quality results, which is likely to further boost the market growth. The global market for centrifugal dental casting machines is poised for significant expansion as dental practices continue to modernize and adopt advanced technologies.

Low Frequency, IF, High Frequency in the Centrifugal Dental Casting Machine - Global Market:

Centrifugal dental casting machines operate at different frequency levels, each serving specific purposes and offering distinct advantages. Low-frequency machines are typically used for casting larger dental prosthetics or when working with metals that require a slower casting process to ensure proper filling of the mold. These machines are often favored for their ability to produce detailed and accurate castings with minimal porosity, which is crucial for the durability and functionality of dental restorations. Intermediate frequency (IF) machines strike a balance between speed and precision, making them suitable for a wide range of dental applications. They are versatile and can handle various types of metals, providing dental technicians with the flexibility to produce different types of prosthetics efficiently. High-frequency machines, on the other hand, are designed for rapid casting processes, making them ideal for high-volume production environments. These machines are often used in dental laboratories that require quick turnaround times without compromising on the quality of the castings. The choice of frequency depends on the specific needs of the dental practice or laboratory, as well as the type of materials being used. Each frequency level offers unique benefits, and understanding these can help dental professionals select the right machine for their specific requirements. As the global market for centrifugal dental casting machines continues to grow, manufacturers are investing in research and development to enhance the capabilities of these machines, offering more advanced features and improved performance. This includes innovations such as digital controls, automated processes, and enhanced safety features, which are designed to improve the user experience and ensure consistent, high-quality results. The demand for these machines is also influenced by the increasing complexity of dental procedures and the need for precision in dental restorations. As dental technology continues to evolve, the market for centrifugal dental casting machines is expected to expand, driven by the need for efficient and reliable casting solutions.

Hospital, Specialist Clinic, Other in the Centrifugal Dental Casting Machine - Global Market:

Centrifugal dental casting machines are widely used in various healthcare settings, including hospitals, specialist clinics, and other facilities, each with its unique requirements and applications. In hospitals, these machines are often part of the dental department, where they are used to produce dental prosthetics for patients undergoing complex dental procedures. Hospitals benefit from having in-house casting capabilities, as it allows for quicker production and customization of dental restorations, reducing the waiting time for patients. This is particularly important in cases where immediate dental care is required, such as after an accident or surgery. Specialist clinics, which focus on specific areas of dental care, also rely heavily on centrifugal dental casting machines. These clinics often deal with complex cases that require highly customized dental prosthetics, and having access to advanced casting technology enables them to provide tailored solutions to their patients. The precision and efficiency of these machines are crucial in ensuring that the prosthetics fit perfectly and function effectively, enhancing patient satisfaction and outcomes. Other facilities, such as dental laboratories and educational institutions, also utilize centrifugal dental casting machines for various purposes. Dental laboratories, for instance, are often tasked with producing large volumes of dental prosthetics for multiple clients, and the speed and accuracy of these machines are essential in meeting the demand. Educational institutions, on the other hand, use these machines as part of their training programs, providing students with hands-on experience in modern dental technology. The versatility and reliability of centrifugal dental casting machines make them an invaluable tool in the dental industry, supporting a wide range of applications and contributing to the overall improvement of dental care services. As the global market for these machines continues to grow, their usage in different healthcare settings is expected to expand, driven by the increasing demand for high-quality dental restorations and the ongoing advancements in dental technology.

Centrifugal Dental Casting Machine - Global Market Outlook:

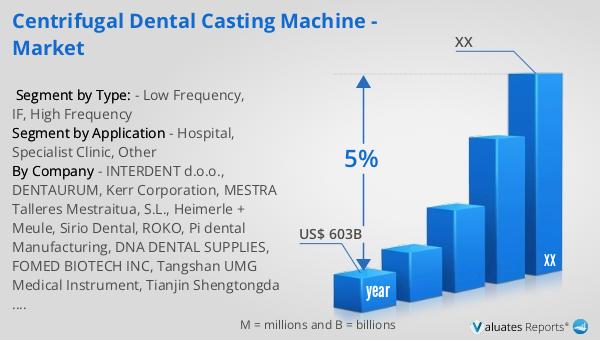

Based on our analysis, the global market for medical devices, including centrifugal dental casting machines, is projected to reach approximately $603 billion in 2023. This substantial market size reflects the growing demand for advanced medical technologies and devices across various healthcare sectors. Over the next six years, the market is anticipated to grow at a compound annual growth rate (CAGR) of 5%. This growth is driven by several factors, including the increasing prevalence of chronic diseases, the aging population, and the rising demand for minimally invasive procedures. The medical device industry is also benefiting from technological advancements, which are leading to the development of more sophisticated and efficient devices. As healthcare providers continue to adopt these advanced technologies, the demand for medical devices is expected to rise, further fueling market growth. Additionally, the increasing focus on improving healthcare infrastructure and expanding access to medical services in emerging markets is contributing to the expansion of the global medical device market. As a result, manufacturers are investing in research and development to create innovative products that meet the evolving needs of healthcare providers and patients. The global market for medical devices, including centrifugal dental casting machines, is poised for significant growth, driven by the ongoing advancements in medical technology and the increasing demand for high-quality healthcare services.

| Report Metric | Details |

| Report Name | Centrifugal Dental Casting Machine - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | INTERDENT d.o.o., DENTAURUM, Kerr Corporation, MESTRA Talleres Mestraitua, S.L., Heimerle + Meule, Sirio Dental, ROKO, Pi dental Manufacturing, DNA DENTAL SUPPLIES, FOMED BIOTECH INC, Tangshan UMG Medical Instrument, Tianjin Shengtongda Experimental Equipment Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |