What is Global Optical Coherence Tomography for Industrial Market?

Global Optical Coherence Tomography (OCT) for the industrial market is a cutting-edge imaging technology that leverages light waves to capture high-resolution, cross-sectional images of materials and structures. Unlike traditional imaging methods, OCT provides non-destructive testing capabilities, allowing industries to inspect and analyze the internal features of various materials without causing any damage. This technology is particularly valuable in sectors where precision and accuracy are paramount, such as manufacturing, quality control, and research and development. By using OCT, industries can detect defects, measure thickness, and assess the structural integrity of materials with unparalleled detail. The global market for industrial OCT is expanding as more industries recognize the benefits of integrating this technology into their processes. With advancements in OCT technology, such as increased imaging speed and resolution, the potential applications continue to grow, making it an essential tool for industries aiming to enhance their quality assurance and production efficiency. As industries strive for higher standards and more efficient operations, the adoption of OCT is expected to rise, driving further innovation and development in this field.

2D-OCT, 3D-OCT in the Global Optical Coherence Tomography for Industrial Market:

2D-OCT and 3D-OCT are two primary modalities of Optical Coherence Tomography that are gaining traction in the industrial market. 2D-OCT, or two-dimensional Optical Coherence Tomography, provides cross-sectional images of materials, offering a detailed view of their internal structures. This modality is particularly useful for applications where a single plane of imaging is sufficient to assess the quality or detect defects in a material. For instance, in the manufacturing of thin films or coatings, 2D-OCT can be employed to measure thickness and uniformity, ensuring that the final product meets the required specifications. The simplicity and speed of 2D-OCT make it an attractive option for industries that require quick and reliable inspection methods. On the other hand, 3D-OCT, or three-dimensional Optical Coherence Tomography, offers a more comprehensive view by capturing volumetric images of materials. This modality is essential for applications where understanding the full spatial structure of a material is crucial. In industries such as aerospace and automotive, 3D-OCT can be used to inspect complex components, ensuring that they are free from defects and meet safety standards. The ability to visualize the entire volume of a component allows for a more thorough analysis, reducing the risk of overlooking critical defects that could compromise the integrity of the final product. The industrial market is increasingly adopting 3D-OCT due to its ability to provide detailed insights into the internal structures of materials. This technology is particularly beneficial in sectors where precision and reliability are critical, such as semiconductor manufacturing and microelectronics. By using 3D-OCT, manufacturers can detect minute defects and variations in materials that could affect the performance of electronic components. This level of detail is essential for ensuring the quality and reliability of products in highly competitive markets. Moreover, the integration of 3D-OCT with advanced data analysis and machine learning techniques is opening new possibilities for automated inspection and quality control. By leveraging these technologies, industries can enhance their production processes, reduce waste, and improve overall efficiency. The ability to quickly and accurately assess the quality of materials and components is becoming a key differentiator for companies looking to maintain a competitive edge in the global market. As the demand for high-quality products continues to rise, the adoption of 2D-OCT and 3D-OCT in the industrial market is expected to grow. These technologies offer significant advantages in terms of speed, accuracy, and non-destructive testing capabilities, making them indispensable tools for industries aiming to enhance their quality assurance processes. With ongoing advancements in OCT technology, the potential applications and benefits of 2D-OCT and 3D-OCT are set to expand, driving further innovation and development in this field.

Materials and Textiles, Aviation and Automotive, Display Technology, Laser Material Processing, NDT, Others in the Global Optical Coherence Tomography for Industrial Market:

Global Optical Coherence Tomography (OCT) is revolutionizing various industrial sectors by providing advanced imaging solutions that enhance quality control and inspection processes. In the materials and textiles industry, OCT is used to inspect the internal structure of fabrics and composites, ensuring that they meet the required standards for strength and durability. By providing detailed images of the internal layers of materials, OCT helps manufacturers identify defects and inconsistencies that could affect the performance of the final product. This technology is particularly valuable in the production of high-performance textiles and advanced composites used in aerospace and automotive applications. In the aviation and automotive industries, OCT is employed to inspect critical components and assemblies, ensuring that they are free from defects and meet stringent safety standards. The ability to capture high-resolution images of complex structures allows engineers to detect minute defects that could compromise the integrity of components. This is particularly important in the production of lightweight materials and advanced composites, where even small defects can have significant implications for safety and performance. By integrating OCT into their inspection processes, manufacturers can enhance the reliability and safety of their products, reducing the risk of costly recalls and failures. Display technology is another area where OCT is making a significant impact. The production of high-resolution displays requires precise control over the thickness and uniformity of various layers. OCT provides manufacturers with the ability to measure these parameters with high accuracy, ensuring that the final product meets the required specifications. This technology is particularly valuable in the production of OLED and flexible displays, where maintaining uniformity and consistency is critical to achieving the desired performance and visual quality. In laser material processing, OCT is used to monitor and control the laser machining process, ensuring that the desired material modifications are achieved with precision. By providing real-time feedback on the material's response to laser processing, OCT enables manufacturers to optimize their processes, reducing waste and improving efficiency. This technology is particularly valuable in applications where precision and accuracy are critical, such as the production of microelectronics and medical devices. Non-destructive testing (NDT) is another area where OCT is gaining traction. The ability to inspect materials and components without causing damage is a significant advantage in industries where maintaining the integrity of the product is essential. OCT provides detailed images of the internal structure of materials, allowing engineers to detect defects and assess the quality of components without the need for destructive testing methods. This technology is particularly valuable in the aerospace and automotive industries, where ensuring the safety and reliability of components is paramount. In addition to these applications, OCT is also being used in other industries, such as pharmaceuticals and food processing, where quality control and inspection are critical. By providing detailed images of the internal structure of products, OCT helps manufacturers ensure that their products meet the required standards for quality and safety. As industries continue to seek ways to enhance their quality assurance processes, the adoption of OCT is expected to grow, driving further innovation and development in this field.

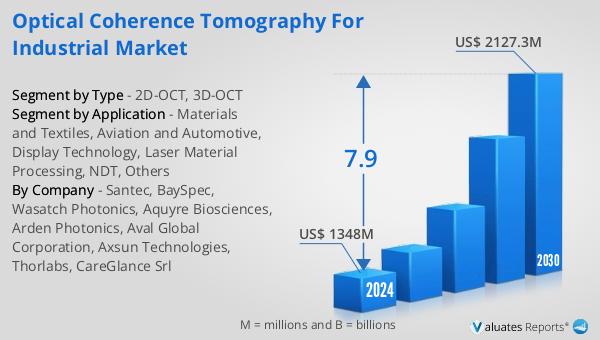

Global Optical Coherence Tomography for Industrial Market Outlook:

The global market for Optical Coherence Tomography in industrial applications is anticipated to experience significant growth, with projections indicating an increase from $1,348 million in 2024 to $2,127.3 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 7.9% during the forecast period. This growth is driven by the increasing demand for advanced imaging solutions across various industries, as companies strive to enhance their quality control and inspection processes. In the construction machinery sector, for instance, sales in Europe saw a 24% increase in 2021, with revenues reaching approximately $22 billion in 2022. Meanwhile, the U.S. market reported sales of about $36 billion in construction machinery in the same year. Asian companies hold a dominant position in this market, accounting for 50% of the revenue, followed by Europe and North America, which account for 26% and 23%, respectively. This market outlook underscores the growing importance of Optical Coherence Tomography in industrial applications, as companies seek to leverage this technology to improve their production processes and maintain a competitive edge in the global market. As industries continue to adopt OCT for its non-destructive testing capabilities and high-resolution imaging, the market is poised for continued growth and innovation.

| Report Metric | Details |

| Report Name | Optical Coherence Tomography for Industrial Market |

| Accounted market size in 2024 | US$ 1348 million |

| Forecasted market size in 2030 | US$ 2127.3 million |

| CAGR | 7.9 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Santec, BaySpec, Wasatch Photonics, Aquyre Biosciences, Arden Photonics, Aval Global Corporation, Axsun Technologies, Thorlabs, CareGlance Srl |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |