What is Global Styrene Monomer (SM) Market?

The Global Styrene Monomer (SM) Market refers to the worldwide industry involved in the production, distribution, and consumption of styrene monomer. Styrene monomer is a crucial chemical used primarily in the manufacturing of various plastic and rubber products. It is a colorless, oily liquid that is derived from petroleum and natural gas byproducts. The demand for styrene monomer is driven by its extensive application in producing polystyrene, acrylonitrile butadiene styrene (ABS), styrene-acrylonitrile (SAN), unsaturated polyester resins (UPR), and styrene-butadiene rubber (SBR). These materials are essential in numerous industries, including automotive, construction, packaging, and consumer goods. The global market for styrene monomer is influenced by factors such as economic growth, industrialization, technological advancements, and environmental regulations. As industries continue to expand and innovate, the demand for styrene monomer is expected to grow, making it a significant component of the global chemical market.

Ethylbenzene Dehydrogenation Method, Ethylbenzene Oxidation Method in the Global Styrene Monomer (SM) Market:

The Ethylbenzene Dehydrogenation Method and Ethylbenzene Oxidation Method are two primary processes used in the production of styrene monomer (SM) on a global scale. The Ethylbenzene Dehydrogenation Method is the most widely used process, accounting for the majority of styrene production. In this method, ethylbenzene is heated in the presence of steam and a catalyst, typically iron oxide, to produce styrene and hydrogen. The reaction takes place at high temperatures, usually between 600 to 650 degrees Celsius. The hydrogen produced in the process can be used as a fuel or in other chemical processes, making it a relatively efficient method. The dehydrogenation process is favored for its high yield and relatively low production costs. On the other hand, the Ethylbenzene Oxidation Method involves the oxidation of ethylbenzene to produce styrene. This method is less common and involves a more complex series of reactions. Ethylbenzene is first oxidized to produce ethylbenzene hydroperoxide, which is then decomposed to produce styrene and acetophenone. The acetophenone can be further processed to produce additional styrene or other valuable chemicals. This method is generally less efficient and more costly compared to the dehydrogenation method. However, it can be advantageous in certain situations where the byproducts are also in demand. Both methods have their own set of advantages and disadvantages, and the choice of method depends on various factors such as feedstock availability, production scale, and economic considerations. The global styrene monomer market relies heavily on these production methods to meet the growing demand for styrene-based products. As the market continues to evolve, advancements in production technologies and processes are expected to play a crucial role in shaping the future of the styrene monomer industry.

PS, ABS/SAN, UPR, SBR in the Global Styrene Monomer (SM) Market:

The Global Styrene Monomer (SM) Market finds extensive usage in various applications, including Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS) and Styrene Acrylonitrile (SAN), Unsaturated Polyester Resins (UPR), and Styrene-Butadiene Rubber (SBR). Polystyrene (PS) is one of the most common plastics produced from styrene monomer. It is widely used in packaging, disposable cutlery, plastic models, CD and DVD cases, and various other consumer products. Its popularity stems from its ease of molding, cost-effectiveness, and versatility. Acrylonitrile Butadiene Styrene (ABS) and Styrene Acrylonitrile (SAN) are engineering plastics known for their toughness, rigidity, and resistance to impact and heat. ABS is commonly used in automotive parts, electronic housings, and consumer goods like LEGO bricks, while SAN is used in applications requiring clarity and chemical resistance, such as kitchenware and medical devices. Unsaturated Polyester Resins (UPR) are another significant application of styrene monomer. UPRs are used in the production of fiberglass-reinforced plastics, which are essential in the construction, marine, and automotive industries. These resins provide excellent mechanical properties, chemical resistance, and durability, making them ideal for a wide range of applications. Styrene-Butadiene Rubber (SBR) is a synthetic rubber derived from styrene and butadiene. It is widely used in the production of tires, conveyor belts, gaskets, and various other rubber products. SBR offers good abrasion resistance, aging stability, and overall performance, making it a preferred choice in the rubber industry. The versatility and wide range of applications of styrene monomer make it a critical component in various industries, driving the growth and development of the global styrene monomer market.

Global Styrene Monomer (SM) Market Outlook:

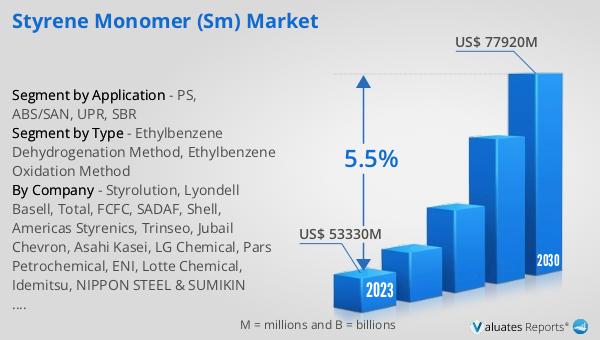

The global Styrene Monomer (SM) market is anticipated to expand from USD 56,510 million in 2024 to USD 77,920 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 5.5% over the forecast period. China stands as the largest market for styrene monomer, holding approximately 21% of the market share. Europe follows closely, accounting for around 18% of the market share. The top three companies in the industry collectively occupy about 17% of the market share. This growth is driven by the increasing demand for styrene-based products across various industries, including automotive, construction, packaging, and consumer goods. The expansion of these industries, coupled with technological advancements and economic growth, is expected to fuel the demand for styrene monomer. Additionally, environmental regulations and the push for sustainable practices are influencing the market dynamics, leading to innovations in production processes and the development of eco-friendly alternatives. As the market continues to evolve, the strategic initiatives and investments by key players will play a crucial role in shaping the future of the global styrene monomer market.

| Report Metric | Details |

| Report Name | Styrene Monomer (SM) Market |

| Accounted market size in 2024 | US$ 56510 million |

| Forecasted market size in 2030 | US$ 77920 million |

| CAGR | 5.5 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Styrolution, Lyondell Basell, Total, FCFC, SADAF, Shell, Americas Styrenics, Trinseo, Jubail Chevron, Asahi Kasei, LG Chemical, Pars Petrochemical, ENI, Lotte Chemical, Idemitsu, NIPPON STEEL & SUMIKIN CHEMICAL, Westlake Chemical, Denka, Sinopec, CNPC, CSPC, Tianjin Dagu Chemical, Shuangliang Leasty Chemical, New Solar, Huajin Chemical, Donghao Chemical, Yuhuang Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |