What is Global Specialty Carbon Blacks for Plastics Market?

Global Specialty Carbon Blacks for Plastics Market refers to a niche segment within the broader carbon black industry, focusing specifically on high-performance carbon blacks used in plastic applications. These specialty carbon blacks are engineered to enhance the properties of plastics, such as improving their color, UV resistance, conductivity, and mechanical strength. They are used in a variety of plastic products, ranging from automotive parts to consumer electronics, and are essential for ensuring the durability and performance of these items. The market for these specialty carbon blacks is driven by the growing demand for high-quality plastics in various industries, including automotive, electronics, and consumer goods. As industries continue to innovate and develop new plastic products, the need for specialty carbon blacks is expected to rise, making this market a critical component of the global plastics industry.

Lamp Black, Acetylene Black, Gas Black, Other Types in the Global Specialty Carbon Blacks for Plastics Market:

Lamp Black, Acetylene Black, Gas Black, and other types of specialty carbon blacks each have unique properties and applications within the Global Specialty Carbon Blacks for Plastics Market. Lamp Black is produced by burning oil in a limited supply of air, resulting in a fine, soot-like powder. It is known for its excellent color properties and is often used in applications where a deep, rich black color is desired. Acetylene Black, on the other hand, is produced by the thermal decomposition of acetylene gas. This type of carbon black is highly conductive and is used in applications requiring electrical conductivity, such as in conductive plastics and battery components. Gas Black is produced by the incomplete combustion of natural gas and is characterized by its small particle size and high surface area. It is used in applications where a high level of dispersion and a smooth surface finish are required, such as in high-gloss plastics and coatings. Other types of specialty carbon blacks include thermal black and furnace black, each with their own unique production processes and properties. Thermal black is produced by the thermal decomposition of hydrocarbons in the absence of air, resulting in a coarse, low-structure carbon black that is used in applications requiring high loadings and low viscosity. Furnace black, the most common type of carbon black, is produced by the incomplete combustion of hydrocarbons in a controlled environment. It is used in a wide range of applications, from reinforcing fillers in rubber to pigments in plastics and coatings. Each type of specialty carbon black offers distinct advantages and is selected based on the specific requirements of the application, making them essential components in the production of high-performance plastics.

Automobile, Electrical Engineering&Electronics, Consumer Products, Industrial Parts in the Global Specialty Carbon Blacks for Plastics Market:

The usage of Global Specialty Carbon Blacks for Plastics Market spans several key areas, including the automobile industry, electrical engineering and electronics, consumer products, and industrial parts. In the automobile industry, specialty carbon blacks are used to enhance the durability, UV resistance, and color of various plastic components, such as bumpers, dashboards, and interior trims. These properties are crucial for ensuring the longevity and aesthetic appeal of automotive parts, which are exposed to harsh environmental conditions. In electrical engineering and electronics, specialty carbon blacks are used to improve the conductivity and electromagnetic interference (EMI) shielding of plastic components. This is particularly important in the production of electronic devices, where reliable performance and protection against EMI are critical. Specialty carbon blacks are also used in the production of conductive plastics for applications such as antistatic packaging and electronic housings. In the consumer products sector, specialty carbon blacks are used to enhance the appearance, durability, and performance of a wide range of plastic items, from household appliances to toys. These carbon blacks help to improve the color, UV resistance, and mechanical strength of consumer products, ensuring they meet the high standards expected by consumers. In industrial parts, specialty carbon blacks are used to improve the mechanical properties and chemical resistance of plastic components used in various industrial applications. This includes everything from pipes and fittings to seals and gaskets, where enhanced performance and durability are essential. Overall, the use of specialty carbon blacks in these areas helps to improve the quality and performance of plastic products, making them more reliable and longer-lasting.

Global Specialty Carbon Blacks for Plastics Market Outlook:

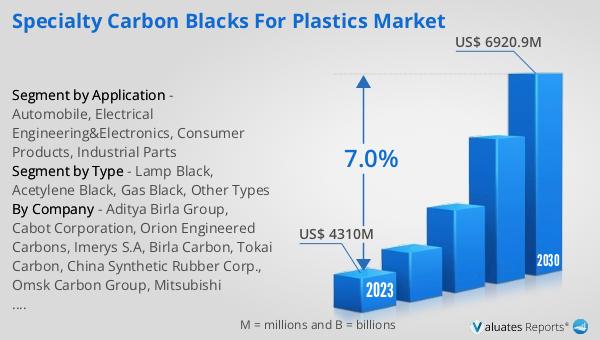

The global market for Specialty Carbon Blacks for Plastics was valued at $4.31 billion in 2023 and is projected to grow significantly, reaching $6.92 billion by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 7.0% from 2024 to 2030. This indicates a robust demand for specialty carbon blacks, driven by their essential role in enhancing the properties of plastics used across various industries. The increasing need for high-performance plastics in sectors such as automotive, electronics, and consumer goods is a key factor contributing to this market growth. As industries continue to innovate and develop new plastic products, the demand for specialty carbon blacks is expected to rise, making this market a critical component of the global plastics industry.

| Report Metric | Details |

| Report Name | Specialty Carbon Blacks for Plastics Market |

| Accounted market size in 2023 | US$ 4310 million |

| Forecasted market size in 2030 | US$ 6920.9 million |

| CAGR | 7.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Aditya Birla Group, Cabot Corporation, Orion Engineered Carbons, Imerys S.A, Birla Carbon, Tokai Carbon, China Synthetic Rubber Corp., Omsk Carbon Group, Mitsubishi Chemical, Denka Company, Himadri Speciality Chemical Limited, Continental Carbon, RP-Sanjiv Goenka Group(PCBL), PentaCarbon GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |