What is Global Sintered Titanium Filters Market?

The global sintered titanium filters market is a specialized segment within the filtration industry, focusing on the production and application of filters made from sintered titanium. These filters are created by compressing and heating titanium powder until it fuses into a solid but porous structure. This unique manufacturing process results in filters that are highly durable, resistant to corrosion, and capable of withstanding extreme temperatures and pressures. Sintered titanium filters are widely used in various industries due to their excellent filtration efficiency and long service life. They are particularly valued in applications where purity and reliability are critical, such as in the medical, chemical, and nuclear industries. The market for these filters is driven by the increasing demand for high-performance filtration solutions that can meet stringent regulatory standards and operational requirements. As industries continue to evolve and seek more efficient and sustainable filtration technologies, the global sintered titanium filters market is expected to grow, offering innovative solutions to complex filtration challenges.

Sintered Fiber, Sintered Powder, Sintered Mesh in the Global Sintered Titanium Filters Market:

Sintered titanium filters come in various forms, including sintered fiber, sintered powder, and sintered mesh, each with distinct characteristics and applications. Sintered fiber filters are made by bonding titanium fibers together, creating a porous structure that offers high permeability and excellent filtration efficiency. These filters are particularly effective in applications requiring fine filtration and high flow rates, such as in the medical and pharmaceutical industries. Sintered powder filters, on the other hand, are produced by compressing and sintering titanium powder, resulting in a robust and uniform porous structure. These filters are known for their high mechanical strength, thermal stability, and resistance to chemical corrosion, making them ideal for use in harsh environments like the chemical and petrochemical industries. Sintered mesh filters are created by layering and sintering titanium wire mesh, providing a combination of high strength and precise filtration capabilities. These filters are often used in applications where both mechanical durability and fine filtration are required, such as in the aerospace and automotive industries. Each type of sintered titanium filter offers unique advantages, allowing them to be tailored to specific industrial needs and operational conditions. The versatility and reliability of these filters make them a preferred choice in various sectors, driving the growth and innovation within the global sintered titanium filters market.

Metallurgy Industry, Power Industry, Chemical Industry, Medical Industry, Electronics Industry, Automotive Industry, Nuclear and Energy Industry, Other in the Global Sintered Titanium Filters Market:

The global sintered titanium filters market finds extensive usage across a wide range of industries due to the unique properties and advantages of these filters. In the metallurgy industry, sintered titanium filters are used for the filtration of molten metals and gases, ensuring the removal of impurities and enhancing the quality of the final product. The power industry utilizes these filters in gas turbines and other high-temperature applications, where their thermal stability and corrosion resistance are crucial. In the chemical industry, sintered titanium filters are employed for the filtration of aggressive chemicals and solvents, providing reliable performance in harsh environments. The medical industry benefits from the biocompatibility and high purity of sintered titanium filters, which are used in medical devices, implants, and pharmaceutical manufacturing processes. The electronics industry relies on these filters for the production of high-purity electronic components and the filtration of process gases and liquids. In the automotive industry, sintered titanium filters are used in fuel and oil filtration systems, contributing to the efficiency and longevity of engines. The nuclear and energy industry employs these filters for the filtration of radioactive materials and other critical applications, where safety and reliability are paramount. Other industries, such as food and beverage, water treatment, and aerospace, also utilize sintered titanium filters for their superior filtration capabilities and durability. The widespread adoption of these filters across diverse sectors underscores their importance and the growing demand for advanced filtration solutions in the global market.

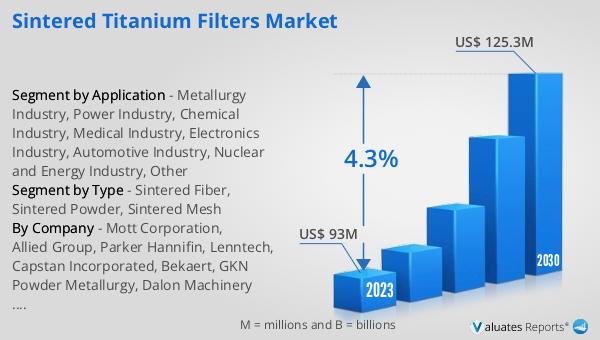

Global Sintered Titanium Filters Market Outlook:

The global sintered titanium filters market was valued at approximately US$ 93 million in 2023 and is projected to reach around US$ 125.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-performance filtration solutions across various industries, including medical, chemical, and nuclear sectors. The unique properties of sintered titanium filters, such as their durability, corrosion resistance, and ability to withstand extreme temperatures, make them highly sought after in applications where reliability and efficiency are critical. As industries continue to evolve and face more stringent regulatory standards, the need for advanced filtration technologies is expected to rise, further propelling the market growth. The ongoing advancements in manufacturing processes and the development of new applications for sintered titanium filters are also contributing to the market's expansion. Overall, the global sintered titanium filters market is poised for steady growth, driven by the increasing adoption of these filters in various high-demand applications.

| Report Metric | Details |

| Report Name | Sintered Titanium Filters Market |

| Accounted market size in 2023 | US$ 93 million |

| Forecasted market size in 2030 | US$ 125.3 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mott Corporation, Allied Group, Parker Hannifin, Lenntech, Capstan Incorporated, Bekaert, GKN Powder Metallurgy, Dalon Machinery Co.,Ltd., Van Borselen, Nippon Seisen Co.,Ltd., Fuji Filter, Filson Filter, Blacksand Technologies LLC, OSAKA Titanium Technologies Co.,Ltd., VSMPO-AVISMA, Kumar Process Consultants&Chemicals Pvt.Ltd., Baoji Saga porous filter Co.,Ltd, HENGKO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |