What is Global Separate Aluminum Cutting Machine Market?

The Global Separate Aluminum Cutting Machine Market refers to the industry focused on the production and sale of machines specifically designed to cut aluminum materials. These machines are essential in various industries due to aluminum's widespread use, thanks to its lightweight, durability, and resistance to corrosion. The market encompasses a range of machines, from manual to fully automated systems, catering to different levels of production needs and precision requirements. The demand for these machines is driven by the growing use of aluminum in sectors such as automotive, aerospace, construction, and manufacturing. As industries continue to innovate and seek more efficient production methods, the need for specialized aluminum cutting machines is expected to rise. This market is characterized by technological advancements, with manufacturers constantly developing new features to enhance cutting precision, speed, and safety. Additionally, the market is influenced by factors such as raw material prices, technological advancements, and the overall economic environment.

Automatic, Semi-automatic in the Global Separate Aluminum Cutting Machine Market:

In the Global Separate Aluminum Cutting Machine Market, machines can be broadly categorized into automatic and semi-automatic types. Automatic aluminum cutting machines are designed to perform cutting operations with minimal human intervention. These machines are equipped with advanced features such as programmable logic controllers (PLCs), computer numerical control (CNC) systems, and automated feeding mechanisms. The primary advantage of automatic machines is their ability to deliver high precision and consistency in cutting operations, which is crucial for industries that require exact specifications, such as aerospace and automotive manufacturing. These machines can handle large volumes of work with high efficiency, reducing labor costs and minimizing the risk of human error. On the other hand, semi-automatic aluminum cutting machines require some level of manual intervention. While they may incorporate certain automated features, such as motorized cutting heads or automated clamping systems, the operator still plays a significant role in the cutting process. Semi-automatic machines are typically more affordable than their fully automatic counterparts and offer greater flexibility for smaller production runs or custom cutting tasks. They are often used in workshops and small to medium-sized enterprises where the volume of work does not justify the investment in fully automated systems. Both types of machines have their own set of advantages and are chosen based on the specific needs and budget constraints of the user. The choice between automatic and semi-automatic machines also depends on the complexity of the cutting tasks, the required precision, and the production volume. As technology continues to evolve, the line between automatic and semi-automatic machines is becoming increasingly blurred, with many modern machines offering a blend of both features to provide optimal performance and versatility.

Vehicles, Airplanes, Others in the Global Separate Aluminum Cutting Machine Market:

The usage of Global Separate Aluminum Cutting Machines spans across various industries, including vehicles, airplanes, and others. In the automotive industry, these machines are crucial for manufacturing various components such as body panels, engine parts, and structural elements. Aluminum's lightweight properties make it an ideal material for vehicles, contributing to improved fuel efficiency and reduced emissions. Aluminum cutting machines enable precise and efficient cutting of aluminum sheets and extrusions, ensuring that the components meet the stringent quality standards required in the automotive sector. In the aerospace industry, aluminum cutting machines play a vital role in the production of aircraft components. Aluminum is widely used in the construction of airplanes due to its high strength-to-weight ratio and resistance to corrosion. Cutting machines are used to fabricate parts such as fuselage panels, wing sections, and internal structural components. The precision and accuracy of these machines are critical in ensuring the safety and performance of the aircraft. Beyond vehicles and airplanes, aluminum cutting machines are also used in various other industries. In the construction sector, they are employed to cut aluminum profiles for windows, doors, and curtain walls. The electronics industry uses these machines to manufacture components such as heat sinks and enclosures. Additionally, aluminum cutting machines are used in the production of consumer goods, furniture, and packaging materials. The versatility and efficiency of these machines make them indispensable in any industry that utilizes aluminum as a primary material.

Global Separate Aluminum Cutting Machine Market Outlook:

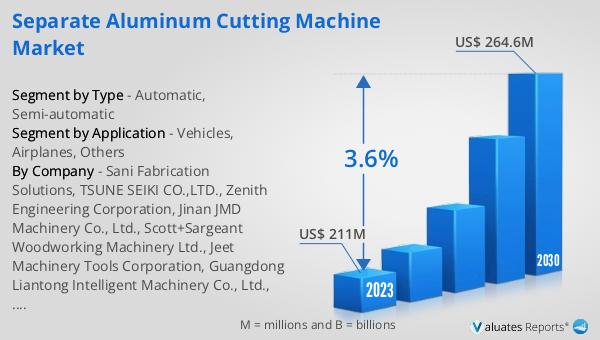

The global Separate Aluminum Cutting Machine market was valued at US$ 211 million in 2023 and is anticipated to reach US$ 264.6 million by 2030, witnessing a CAGR of 3.6% during the forecast period 2024-2030. This market growth can be attributed to the increasing demand for aluminum cutting machines across various industries, driven by the material's desirable properties and the need for precise and efficient cutting solutions. As industries continue to innovate and seek more efficient production methods, the demand for specialized aluminum cutting machines is expected to rise. The market is characterized by technological advancements, with manufacturers constantly developing new features to enhance cutting precision, speed, and safety. Additionally, the market is influenced by factors such as raw material prices, technological advancements, and the overall economic environment. The growing use of aluminum in sectors such as automotive, aerospace, construction, and manufacturing is a significant driver for the market. As industries continue to innovate and seek more efficient production methods, the need for specialized aluminum cutting machines is expected to rise. This market is characterized by technological advancements, with manufacturers constantly developing new features to enhance cutting precision, speed, and safety. Additionally, the market is influenced by factors such as raw material prices, technological advancements, and the overall economic environment.

| Report Metric | Details |

| Report Name | Separate Aluminum Cutting Machine Market |

| Accounted market size in 2023 | US$ 211 million |

| Forecasted market size in 2030 | US$ 264.6 million |

| CAGR | 3.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sani Fabrication Solutions, TSUNE SEIKI CO.,LTD., Zenith Engineering Corporation, Jinan JMD Machinery Co., Ltd., Scott+Sargeant Woodworking Machinery Ltd., Jeet Machinery Tools Corporation, Guangdong Liantong Intelligent Machinery Co., Ltd., Zhangjiagang Jiurun Machinery Technology Co., Ltd., Dading, Zhejiang, Shuangdeyu Precision Machinery (Suzhou) Co., Ltd., Shandong Ruiyu Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |