What is Global Robotic Screwdriving System Market?

The Global Robotic Screwdriving System Market refers to the worldwide industry focused on the development, production, and distribution of automated systems designed to drive screws into various materials. These systems are widely used in manufacturing and assembly processes to enhance efficiency, precision, and consistency. By automating the screwdriving process, these systems reduce the need for manual labor, minimize errors, and increase production speed. The market encompasses a range of technologies, including robotic arms, screw feeders, and control systems, which work together to perform screwdriving tasks with high accuracy. Industries such as electronics, automotive, aerospace, and construction are significant users of these systems, leveraging their capabilities to improve product quality and operational efficiency. The market is driven by advancements in robotics and automation technologies, as well as the growing demand for high-quality, reliable assembly processes in various sectors. As industries continue to seek ways to optimize their production lines, the Global Robotic Screwdriving System Market is expected to experience substantial growth.

Servo Drivers, Mechanical Torque Drivers in the Global Robotic Screwdriving System Market:

Servo drivers and mechanical torque drivers are two critical components in the Global Robotic Screwdriving System Market, each playing a unique role in ensuring precise and efficient screwdriving operations. Servo drivers are advanced control systems that manage the movement and operation of robotic arms and screwdriving tools. They use feedback mechanisms to adjust the position, speed, and torque of the screwdriving tool in real-time, ensuring that screws are driven with high precision and consistency. Servo drivers are particularly valuable in applications where accuracy is paramount, such as in electronics manufacturing, where even minor deviations can lead to significant issues. These drivers can be programmed to handle various screw sizes and types, making them versatile and adaptable to different assembly tasks. On the other hand, mechanical torque drivers are tools designed to apply a specific amount of torque to a screw, ensuring that it is tightened to the correct specification. These drivers can be either manual or automated, with the latter being integrated into robotic screwdriving systems. Mechanical torque drivers are essential in applications where the integrity of the assembly depends on the precise application of torque, such as in automotive and aerospace industries. By ensuring that screws are tightened to the correct torque, these drivers help prevent issues such as over-tightening or under-tightening, which can compromise the quality and safety of the final product. Both servo drivers and mechanical torque drivers contribute to the overall efficiency and reliability of robotic screwdriving systems, enabling manufacturers to achieve high levels of precision and consistency in their assembly processes. As the demand for automated assembly solutions continues to grow, the importance of these components in the Global Robotic Screwdriving System Market is expected to increase.

Electronics Manufacturing, Construction, Industrial Assembly, Others in the Global Robotic Screwdriving System Market:

The usage of Global Robotic Screwdriving System Market spans across various industries, including electronics manufacturing, construction, industrial assembly, and others, each benefiting from the enhanced efficiency and precision these systems offer. In electronics manufacturing, robotic screwdriving systems are used to assemble delicate components such as circuit boards, smartphones, and other electronic devices. The high precision and consistency of these systems ensure that screws are driven accurately, reducing the risk of damage to sensitive components and improving the overall quality of the final product. In the construction industry, robotic screwdriving systems are employed to assemble prefabricated structures, install fixtures, and perform other tasks that require precise screwdriving. These systems help reduce labor costs, increase productivity, and ensure that assemblies are completed to exact specifications. In industrial assembly, robotic screwdriving systems are used to assemble a wide range of products, from automotive components to household appliances. The ability to automate the screwdriving process allows manufacturers to increase production speed, reduce errors, and maintain consistent quality across large production runs. Other industries, such as aerospace and medical device manufacturing, also benefit from the use of robotic screwdriving systems. In aerospace, these systems are used to assemble aircraft components, ensuring that screws are driven to precise torque specifications to maintain the safety and integrity of the final product. In medical device manufacturing, robotic screwdriving systems are used to assemble intricate devices with high precision, ensuring that they meet stringent quality and safety standards. Overall, the Global Robotic Screwdriving System Market plays a crucial role in enhancing the efficiency, precision, and reliability of assembly processes across various industries, driving improvements in product quality and operational efficiency.

Global Robotic Screwdriving System Market Outlook:

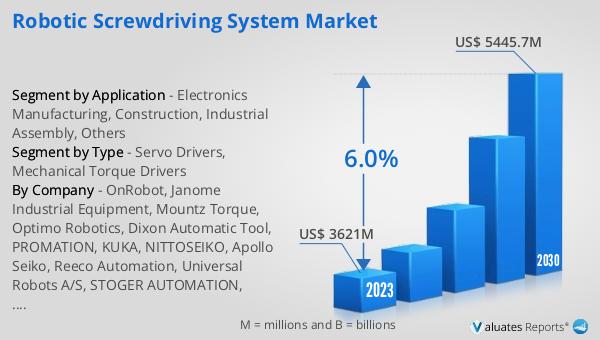

The global Robotic Screwdriving System market was valued at US$ 3621 million in 2023 and is anticipated to reach US$ 5445.7 million by 2030, witnessing a CAGR of 6.0% during the forecast period 2024-2030. This market outlook indicates a significant growth trajectory for the industry, driven by the increasing adoption of automation technologies across various sectors. The rising demand for high-quality, reliable assembly processes is a key factor contributing to this growth. As industries continue to seek ways to optimize their production lines and improve efficiency, the adoption of robotic screwdriving systems is expected to rise. The market's growth is also supported by advancements in robotics and automation technologies, which enhance the capabilities and performance of these systems. With the ongoing trend towards Industry 4.0 and smart manufacturing, the Global Robotic Screwdriving System Market is poised for substantial expansion in the coming years.

| Report Metric | Details |

| Report Name | Robotic Screwdriving System Market |

| Accounted market size in 2023 | US$ 3621 million |

| Forecasted market size in 2030 | US$ 5445.7 million |

| CAGR | 6.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | OnRobot, Janome Industrial Equipment, Mountz Torque, Optimo Robotics, Dixon Automatic Tool, PROMATION, KUKA, NITTOSEIKO, Apollo Seiko, Reeco Automation, Universal Robots A/S, STOGER AUTOMATION, Fancort Industries, Estic, Robotiq |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |