What is Global Photovoltaic Cutting Machine Market?

The global Photovoltaic Cutting Machine market is a specialized sector within the broader solar energy industry. These machines are essential for cutting and shaping photovoltaic materials, which are used to convert sunlight into electricity. The market encompasses various types of cutting machines, including wire saws, laser cutters, and diamond saws, each designed to handle different materials and cutting requirements. These machines are crucial for the production of solar panels, as they ensure precise and efficient cutting of photovoltaic cells, which are the building blocks of solar panels. The demand for photovoltaic cutting machines is driven by the increasing adoption of solar energy worldwide, as countries and companies strive to reduce their carbon footprint and transition to renewable energy sources. The market is characterized by technological advancements, with manufacturers continuously innovating to improve the efficiency and precision of their machines. Additionally, the market is influenced by factors such as government policies, environmental regulations, and the overall growth of the solar energy industry. As the world moves towards a more sustainable future, the global Photovoltaic Cutting Machine market is expected to play a pivotal role in the production of solar energy equipment.

Monocrystalline Silicon, Polycrystalline Silicon in the Global Photovoltaic Cutting Machine Market:

Monocrystalline silicon and polycrystalline silicon are two primary materials used in the global photovoltaic cutting machine market. Monocrystalline silicon, also known as single-crystal silicon, is made from a single continuous crystal structure. It is highly efficient and offers better performance compared to polycrystalline silicon. The production process of monocrystalline silicon involves growing a single crystal from a seed crystal in a process called the Czochralski method. This method results in high-purity silicon wafers that are ideal for high-efficiency solar cells. Monocrystalline silicon cells are known for their uniform appearance and higher energy conversion efficiency, making them a popular choice for residential and commercial solar installations. On the other hand, polycrystalline silicon, also known as multicrystalline silicon, is made from silicon crystals that are melted together. The production process is less complex and less expensive compared to monocrystalline silicon, making it a cost-effective option for solar panel manufacturers. Polycrystalline silicon cells have a bluish hue and a slightly lower efficiency compared to monocrystalline cells. However, they are widely used in large-scale solar power projects due to their lower production costs. The global photovoltaic cutting machine market caters to both monocrystalline and polycrystalline silicon materials, providing specialized cutting machines that ensure precise and efficient cutting of these materials. The choice between monocrystalline and polycrystalline silicon depends on various factors, including cost, efficiency, and application requirements. As the demand for solar energy continues to grow, the market for photovoltaic cutting machines is expected to expand, driven by the need for high-quality and efficient solar cells. Manufacturers in the photovoltaic cutting machine market are continuously innovating to develop advanced cutting technologies that can handle both monocrystalline and polycrystalline silicon materials with precision and efficiency. These advancements are crucial for improving the overall performance and cost-effectiveness of solar panels, thereby contributing to the growth of the solar energy industry.

Solar Battery, Photovoltaic Modules, Others in the Global Photovoltaic Cutting Machine Market:

The global photovoltaic cutting machine market finds extensive usage in various areas, including solar batteries, photovoltaic modules, and other applications. In the context of solar batteries, photovoltaic cutting machines are used to cut and shape the silicon wafers that form the core of solar cells. These cells are then assembled into solar batteries, which store the energy generated by solar panels for later use. The precision and efficiency of photovoltaic cutting machines are crucial for ensuring the high performance and longevity of solar batteries. In the production of photovoltaic modules, which are also known as solar panels, cutting machines play a vital role in shaping the individual solar cells that make up the modules. The accuracy of the cutting process directly impacts the efficiency and reliability of the solar panels. Photovoltaic cutting machines ensure that the cells are cut to the exact specifications required for optimal performance. Additionally, these machines are used in other applications, such as the production of thin-film solar cells and concentrator photovoltaic systems. Thin-film solar cells are made by depositing thin layers of photovoltaic material onto a substrate, and cutting machines are used to shape these layers with precision. Concentrator photovoltaic systems use lenses or mirrors to focus sunlight onto high-efficiency solar cells, and cutting machines are essential for producing the components required for these systems. The versatility and precision of photovoltaic cutting machines make them indispensable in the solar energy industry. As the demand for solar energy continues to rise, the usage of these machines in various applications is expected to grow, driving the overall expansion of the global photovoltaic cutting machine market.

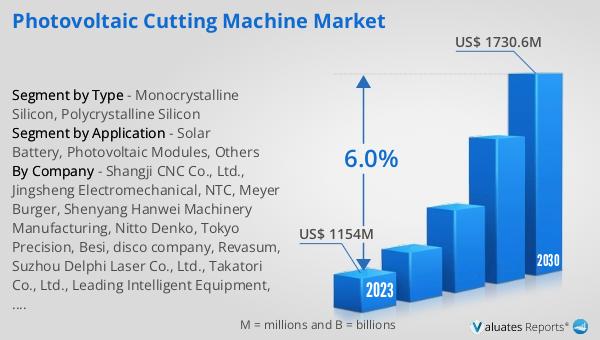

Global Photovoltaic Cutting Machine Market Outlook:

The global Photovoltaic Cutting Machine market was valued at US$ 1154 million in 2023 and is anticipated to reach US$ 1730.6 million by 2030, witnessing a CAGR of 6.0% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for efficient and precise cutting machines in the solar energy industry. As countries and companies worldwide strive to reduce their carbon footprint and transition to renewable energy sources, the need for high-quality photovoltaic cutting machines is expected to rise. These machines play a crucial role in the production of solar panels, ensuring that photovoltaic cells are cut and shaped with precision and efficiency. The market is characterized by continuous technological advancements, with manufacturers innovating to improve the performance and cost-effectiveness of their machines. Factors such as government policies, environmental regulations, and the overall growth of the solar energy industry are expected to influence the market's expansion. As the world moves towards a more sustainable future, the global Photovoltaic Cutting Machine market is poised to play a pivotal role in the production of solar energy equipment, contributing to the broader adoption of solar energy worldwide.

| Report Metric | Details |

| Report Name | Photovoltaic Cutting Machine Market |

| Accounted market size in 2023 | US$ 1154 million |

| Forecasted market size in 2030 | US$ 1730.6 million |

| CAGR | 6.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shangji CNC Co., Ltd., Jingsheng Electromechanical, NTC, Meyer Burger, Shenyang Hanwei Machinery Manufacturing, Nitto Denko, Tokyo Precision, Besi, disco company, Revasum, Suzhou Delphi Laser Co., Ltd., Takatori Co., Ltd., Leading Intelligent Equipment, Yingkou Jinchen Machinery, Komatsu |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |