What is Global Pharmaceutical Film Coatings Market?

The Global Pharmaceutical Film Coatings Market refers to the industry focused on the production and application of thin layers of coating materials on pharmaceutical products such as tablets, capsules, granules, and pellets. These coatings serve multiple purposes, including protecting the drug from environmental factors, masking unpleasant tastes or odors, and controlling the release of the active ingredients. The market encompasses a wide range of coating materials, including polymers, colorants, and plasticizers, which are used to achieve specific functionalities. The demand for pharmaceutical film coatings is driven by the need for improved drug stability, patient compliance, and the growing trend towards advanced drug delivery systems. The market is characterized by continuous innovation and the development of new coating technologies to meet the evolving needs of the pharmaceutical industry.

Aqueous Film Coating, Non-Aqueous Film Coating in the Global Pharmaceutical Film Coatings Market:

Aqueous film coating and non-aqueous film coating are two primary types of coatings used in the Global Pharmaceutical Film Coatings Market. Aqueous film coating involves the use of water as the solvent for the coating material. This type of coating is preferred due to its environmental friendliness and safety, as it eliminates the need for organic solvents that can be harmful to both the environment and human health. Aqueous coatings are typically composed of polymers such as hydroxypropyl methylcellulose (HPMC), polyethylene glycol (PEG), and other water-soluble materials. These coatings are applied to pharmaceutical products to enhance their appearance, improve their stability, and control the release of the active ingredients. The process of applying aqueous film coatings involves spraying the coating solution onto the pharmaceutical product in a controlled environment, followed by drying to form a uniform and smooth coating layer. On the other hand, non-aqueous film coating involves the use of organic solvents such as ethanol, methanol, or acetone as the solvent for the coating material. This type of coating is used when the pharmaceutical product is sensitive to water or when a faster drying time is required. Non-aqueous coatings are typically composed of polymers such as ethylcellulose, cellulose acetate, and other water-insoluble materials. These coatings provide a protective barrier to the pharmaceutical product, enhancing its stability and controlling the release of the active ingredients. The application process for non-aqueous film coatings is similar to that of aqueous coatings, involving the spraying of the coating solution onto the pharmaceutical product and subsequent drying to form a uniform coating layer. Both aqueous and non-aqueous film coatings offer unique advantages and are selected based on the specific requirements of the pharmaceutical product. Aqueous coatings are preferred for their safety and environmental benefits, while non-aqueous coatings are chosen for their ability to provide a faster drying time and suitability for water-sensitive products. The choice of coating type also depends on factors such as the desired release profile of the active ingredients, the stability of the pharmaceutical product, and regulatory requirements. The Global Pharmaceutical Film Coatings Market continues to evolve with advancements in coating technologies, leading to the development of new and improved coating materials that offer enhanced performance and functionality.

Tablet, Capsule, Granules, Pellets in the Global Pharmaceutical Film Coatings Market:

The usage of pharmaceutical film coatings in tablets, capsules, granules, and pellets plays a crucial role in the Global Pharmaceutical Film Coatings Market. Tablets are one of the most common dosage forms in the pharmaceutical industry, and film coatings are widely used to enhance their appearance, improve their stability, and control the release of the active ingredients. Film coatings on tablets can mask unpleasant tastes or odors, making them more palatable for patients. They also provide a protective barrier that shields the tablet from environmental factors such as moisture, light, and air, thereby extending its shelf life. Additionally, film coatings can be used to modify the release profile of the active ingredients, allowing for immediate, delayed, or sustained release, depending on the therapeutic needs. Capsules, another popular dosage form, also benefit from the application of film coatings. Film coatings on capsules can improve their appearance, making them more visually appealing and easier to swallow. They can also enhance the stability of the capsule by providing a protective barrier against environmental factors. In some cases, film coatings are used to control the release of the active ingredients within the capsule, ensuring that the drug is released at the desired rate and location within the gastrointestinal tract. This can be particularly important for drugs that require targeted delivery or have specific release requirements. Granules and pellets are smaller dosage forms that are often used in the formulation of multi-particulate drug delivery systems. Film coatings on granules and pellets serve similar purposes as those on tablets and capsules, including improving their appearance, enhancing their stability, and controlling the release of the active ingredients. Coated granules and pellets can be used to create modified-release formulations, where the drug is released over an extended period or at specific intervals. This can improve patient compliance by reducing the frequency of dosing and providing a more consistent therapeutic effect. In summary, the application of pharmaceutical film coatings to tablets, capsules, granules, and pellets is a critical aspect of the Global Pharmaceutical Film Coatings Market. These coatings offer numerous benefits, including improved appearance, enhanced stability, and controlled release of the active ingredients. The choice of coating material and application method depends on the specific requirements of the pharmaceutical product, including its stability, release profile, and regulatory considerations. As the pharmaceutical industry continues to advance, the demand for innovative and effective film coatings is expected to grow, driving further developments in the Global Pharmaceutical Film Coatings Market.

Global Pharmaceutical Film Coatings Market Outlook:

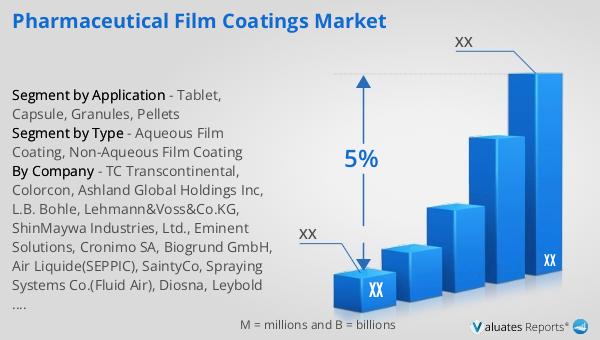

The global pharmaceutical market was valued at approximately 1475 billion USD in 2022, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. In comparison, the chemical drug market has shown significant growth, increasing from 1005 billion USD in 2018 to an estimated 1094 billion USD in 2022. This growth highlights the expanding demand for pharmaceutical products and the continuous advancements in drug development and delivery systems. The pharmaceutical industry is characterized by its dynamic nature, driven by ongoing research and development, regulatory changes, and evolving patient needs. As a result, the market for pharmaceutical film coatings is also expected to experience growth, as these coatings play a vital role in enhancing the stability, appearance, and efficacy of pharmaceutical products. The increasing focus on patient compliance and the development of advanced drug delivery systems further contribute to the demand for innovative film coating solutions.

| Report Metric | Details |

| Report Name | Pharmaceutical Film Coatings Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TC Transcontinental, Colorcon, Ashland Global Holdings Inc, L.B. Bohle, Lehmann&Voss&Co.KG, ShinMaywa Industries, Ltd., Eminent Solutions, Cronimo SA, Biogrund GmbH, Air Liquide(SEPPIC), SaintyCo, Spraying Systems Co.(Fluid Air), Diosna, Leybold GmbH, UL Prospector, PharmaCentral, Savimex, Watlow |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |