What is Global Metal Sintered Filter Market?

The Global Metal Sintered Filter Market refers to the worldwide industry focused on the production and distribution of metal sintered filters. These filters are created through a process called sintering, where powdered metal is heated just below its melting point until the particles adhere to each other. This results in a porous structure that can effectively filter out contaminants from gases and liquids. Metal sintered filters are known for their durability, high-temperature resistance, and ability to withstand harsh environments, making them ideal for various industrial applications. The market encompasses a wide range of products, including sintered fiber, sintered powder, and sintered mesh filters, each designed to meet specific filtration needs. The demand for these filters is driven by their efficiency and reliability in critical applications across multiple industries, such as metallurgy, power, chemical, medical, electronics, automotive, and nuclear energy. As industries continue to seek advanced filtration solutions to improve operational efficiency and product quality, the global metal sintered filter market is expected to grow steadily.

Sintered Fiber, Sintered Powder, Sintered Mesh in the Global Metal Sintered Filter Market:

Sintered fiber, sintered powder, and sintered mesh are three primary types of metal sintered filters used in the global market, each with unique characteristics and applications. Sintered fiber filters are made from fine metal fibers that are sintered together to form a porous structure. These filters are known for their high filtration efficiency, excellent permeability, and ability to capture fine particles. They are commonly used in applications requiring precise filtration, such as in the chemical and pharmaceutical industries. Sintered powder filters, on the other hand, are made from metal powders that are compacted and sintered to create a rigid, porous structure. These filters offer high mechanical strength, thermal stability, and resistance to corrosion, making them suitable for use in harsh environments, such as in the oil and gas industry. Sintered mesh filters are constructed by sintering multiple layers of woven metal mesh together. This results in a filter with uniform pore size and high structural integrity. Sintered mesh filters are often used in applications where high flow rates and low-pressure drops are required, such as in water treatment and hydraulic systems. Each type of sintered filter offers distinct advantages, and the choice of filter depends on the specific requirements of the application. The versatility and reliability of sintered fiber, sintered powder, and sintered mesh filters make them indispensable in various industrial processes, contributing to the growth of the global metal sintered filter market.

Metallurgy Industry, Power Industry, Chemical Industry, Medical Industry, Electronics Industry, Automotive Industry, Nuclear and Energy Industry, Other in the Global Metal Sintered Filter Market:

The global metal sintered filter market finds extensive usage across various industries due to the unique properties and advantages of these filters. In the metallurgy industry, metal sintered filters are used for gas and liquid filtration, ensuring the removal of impurities and enhancing the quality of metal products. They are also employed in the filtration of molten metals, where their high-temperature resistance and durability are crucial. In the power industry, these filters are used in gas turbines, compressors, and other equipment to ensure the efficient operation of power plants by removing contaminants from fuel and lubricants. The chemical industry relies on metal sintered filters for the filtration of aggressive chemicals and solvents, where their corrosion resistance and ability to withstand high pressures are essential. In the medical industry, these filters are used in medical devices and equipment to ensure the sterility and purity of fluids and gases, contributing to patient safety and product quality. The electronics industry uses metal sintered filters in the production of semiconductors and other electronic components, where precise filtration is required to prevent contamination and ensure product reliability. In the automotive industry, these filters are used in fuel and oil filtration systems, enhancing the performance and longevity of vehicles. The nuclear and energy industry employs metal sintered filters in various applications, including the filtration of radioactive gases and liquids, where their robustness and reliability are critical. Additionally, metal sintered filters are used in other industries, such as food and beverage, aerospace, and water treatment, where their unique properties offer significant advantages. The widespread adoption of metal sintered filters across these diverse industries underscores their importance in ensuring the efficiency, safety, and quality of industrial processes, driving the growth of the global metal sintered filter market.

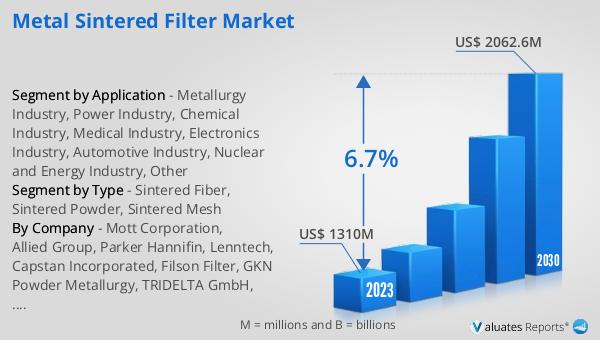

Global Metal Sintered Filter Market Outlook:

The global metal sintered filter market was valued at $1.31 billion in 2023 and is projected to reach approximately $2.06 billion by 2030, reflecting a compound annual growth rate (CAGR) of 6.7% during the forecast period from 2024 to 2030. This growth can be attributed to the increasing demand for efficient and reliable filtration solutions across various industries. As industries continue to evolve and seek advanced technologies to improve operational efficiency and product quality, the need for high-performance filtration systems is becoming more critical. Metal sintered filters, with their durability, high-temperature resistance, and ability to withstand harsh environments, are well-suited to meet these demands. The market's expansion is also driven by the growing awareness of the benefits of using metal sintered filters, such as their long service life, low maintenance requirements, and ability to handle challenging filtration tasks. As a result, more industries are adopting these filters to enhance their processes and ensure the quality and safety of their products. The projected growth of the global metal sintered filter market highlights the increasing importance of advanced filtration solutions in modern industrial applications and the ongoing efforts to improve efficiency and sustainability across various sectors.

| Report Metric | Details |

| Report Name | Metal Sintered Filter Market |

| Accounted market size in 2023 | US$ 1310 million |

| Forecasted market size in 2030 | US$ 2062.6 million |

| CAGR | 6.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mott Corporation, Allied Group, Parker Hannifin, Lenntech, Capstan Incorporated, Filson Filter, GKN Powder Metallurgy, TRIDELTA GmbH, Poral, Bekaert, HENGKO, BLUE, Van Borselen, ExtreMem,Inc., Dalon Machinery Co.,Ltd., Entegris, Nippon Seisen Co.,Ltd., Fuji Filter, Pall Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |