What is Global Medical Cotton Making Machine Market?

The Global Medical Cotton Making Machine Market is a specialized segment within the broader medical device industry, focusing on the production of machines that manufacture medical-grade cotton. These machines are essential for producing cotton products used in various medical settings, such as hospitals, clinics, and other healthcare facilities. Medical cotton is a critical component in wound care, surgical procedures, and general patient care, making the efficiency and reliability of these machines paramount. The market encompasses a range of machines with varying capacities and functionalities, designed to meet the diverse needs of healthcare providers. Factors driving the growth of this market include the increasing demand for medical cotton due to the rising number of surgical procedures, the growing prevalence of chronic diseases, and the expanding healthcare infrastructure globally. Additionally, advancements in technology have led to the development of more sophisticated and efficient machines, further propelling market growth. The market is characterized by a mix of established players and new entrants, all striving to innovate and offer high-quality, cost-effective solutions.

20 - 40 kg/h, 40 - 60 kg/h, Others in the Global Medical Cotton Making Machine Market:

The Global Medical Cotton Making Machine Market can be segmented based on the production capacity of the machines, typically categorized into 20-40 kg/h, 40-60 kg/h, and others. Machines with a production capacity of 20-40 kg/h are generally suitable for smaller healthcare facilities or regions with lower demand for medical cotton. These machines are designed to be compact and efficient, providing a steady supply of medical cotton without requiring significant space or resources. They are ideal for clinics and small hospitals where the volume of cotton needed is manageable. On the other hand, machines with a production capacity of 40-60 kg/h are more suited for larger hospitals and healthcare facilities that require a higher volume of medical cotton. These machines are built to handle more substantial production loads, ensuring a continuous supply of high-quality cotton for various medical applications. They are often equipped with advanced features such as automated controls, quality assurance mechanisms, and energy-efficient operations to optimize performance and reduce operational costs. The "others" category includes machines with capacities outside the 20-60 kg/h range, either lower or higher. These machines cater to specialized needs, such as extremely high-volume production for large-scale healthcare systems or very low-volume production for niche applications. High-capacity machines, for instance, are essential for large hospitals, medical supply manufacturers, and distribution centers that need to produce vast quantities of medical cotton to meet the demands of multiple healthcare facilities. Conversely, low-capacity machines might be used in research settings, specialized clinics, or regions with limited access to healthcare resources. Each category of machines plays a crucial role in ensuring that medical cotton is available where and when it is needed, contributing to the overall efficiency and effectiveness of healthcare delivery. The choice of machine depends on various factors, including the size of the healthcare facility, the volume of medical cotton required, budget constraints, and specific operational needs. As the demand for medical cotton continues to grow, driven by factors such as an aging population, increasing surgical procedures, and the expansion of healthcare services in emerging markets, the Global Medical Cotton Making Machine Market is expected to evolve, with manufacturers focusing on innovation and customization to meet the diverse needs of their customers.

Hospital, Clinic, Others in the Global Medical Cotton Making Machine Market:

The usage of Global Medical Cotton Making Machines is widespread across various healthcare settings, including hospitals, clinics, and other medical facilities. In hospitals, these machines are indispensable for producing the large quantities of medical cotton needed for a wide range of applications. Medical cotton is used extensively in wound care, surgical procedures, and general patient care. Hospitals require a reliable and continuous supply of high-quality cotton to ensure that they can provide the best possible care to their patients. The machines used in hospitals are typically high-capacity models that can produce significant volumes of cotton efficiently and consistently. These machines are often equipped with advanced features such as automated controls, quality assurance mechanisms, and energy-efficient operations to optimize performance and reduce operational costs. In clinics, the demand for medical cotton is also significant, although the volume required is generally lower than in hospitals. Clinics use medical cotton for various purposes, including wound dressing, cleaning, and other routine medical procedures. The machines used in clinics are usually smaller and more compact, designed to produce a steady supply of cotton without requiring significant space or resources. These machines are ideal for clinics that need a reliable source of medical cotton but do not have the same high-volume requirements as larger hospitals. Other medical facilities, such as nursing homes, rehabilitation centers, and outpatient care centers, also rely on medical cotton making machines to meet their needs. These facilities use medical cotton for a variety of purposes, including wound care, patient hygiene, and other medical procedures. The machines used in these settings can vary in size and capacity, depending on the specific needs of the facility. Some may require high-capacity machines to meet the demands of a large patient population, while others may need smaller, more specialized machines for specific applications. In all these settings, the availability of high-quality medical cotton is crucial for providing effective and efficient patient care. The Global Medical Cotton Making Machine Market plays a vital role in ensuring that healthcare providers have access to the tools they need to produce the medical cotton required for their operations. As the demand for medical cotton continues to grow, driven by factors such as an aging population, increasing surgical procedures, and the expansion of healthcare services in emerging markets, the market for medical cotton making machines is expected to evolve, with manufacturers focusing on innovation and customization to meet the diverse needs of their customers.

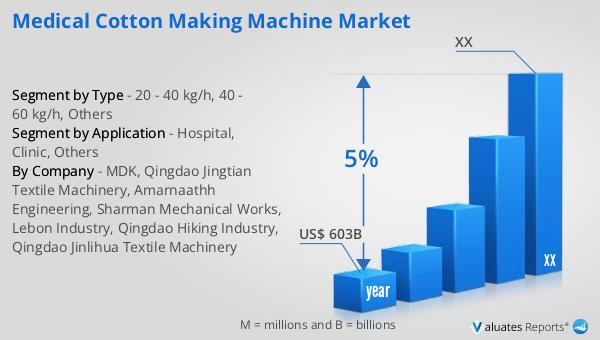

Global Medical Cotton Making Machine Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately USD 603 billion by the year 2023, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth trajectory underscores the increasing demand for medical devices across various healthcare settings, driven by factors such as technological advancements, an aging population, and the rising prevalence of chronic diseases. The medical device market encompasses a wide range of products, including diagnostic equipment, surgical instruments, and therapeutic devices, all of which play a critical role in modern healthcare. The projected growth rate reflects the ongoing innovation and development within the industry, as well as the expanding healthcare infrastructure in emerging markets. As healthcare providers continue to seek out new and improved medical devices to enhance patient care and outcomes, the market is expected to see sustained growth and investment. This positive outlook highlights the importance of the medical device industry in addressing the evolving needs of healthcare systems worldwide and underscores the potential for continued advancements and improvements in medical technology.

| Report Metric | Details |

| Report Name | Medical Cotton Making Machine Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MDK, Qingdao Jingtian Textile Machinery, Amarnaathh Engineering, Sharman Mechanical Works, Lebon Industry, Qingdao Hiking Industry, Qingdao Jinlihua Textile Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |