What is Global Low Shrinkage Adhesive Market?

The Global Low Shrinkage Adhesive Market refers to the worldwide industry focused on the production and distribution of adhesives that exhibit minimal shrinkage during the curing process. These adhesives are crucial in various applications where dimensional stability and precision are essential. Low shrinkage adhesives are designed to maintain their volume and shape, ensuring that the bonded materials remain securely attached without any gaps or misalignments. This market encompasses a wide range of adhesive types, including epoxy resins, polyurethane, and silicone-based adhesives, each tailored to specific industrial needs. The demand for low shrinkage adhesives is driven by their extensive use in sectors such as electronics, aerospace, automotive, and construction, where high-performance bonding solutions are required. As industries continue to advance and the need for reliable, durable, and precise adhesives grows, the Global Low Shrinkage Adhesive Market is expected to expand, offering innovative solutions to meet the evolving demands of various applications.

Bisphenol-a Based Low-shrinkage Epoxy Resins, Cycloaliphatic Low-shrinkage Epoxy Resins, Modified Low-shrinkage Epoxy Resins in the Global Low Shrinkage Adhesive Market:

Bisphenol-a Based Low-shrinkage Epoxy Resins, Cycloaliphatic Low-shrinkage Epoxy Resins, and Modified Low-shrinkage Epoxy Resins are three significant types of adhesives within the Global Low Shrinkage Adhesive Market. Bisphenol-a based low-shrinkage epoxy resins are known for their excellent mechanical properties, chemical resistance, and thermal stability. These resins are widely used in applications requiring high strength and durability, such as in the automotive and aerospace industries. They provide a robust bonding solution that can withstand harsh environmental conditions and mechanical stresses. Cycloaliphatic low-shrinkage epoxy resins, on the other hand, are characterized by their superior electrical insulation properties and resistance to UV radiation. These resins are particularly suitable for electronic applications, where they help in protecting sensitive components from electrical and environmental damage. Their low shrinkage properties ensure that the electronic assemblies remain intact and functional over extended periods. Modified low-shrinkage epoxy resins are tailored to meet specific performance requirements by incorporating various additives and modifiers. These modifications can enhance properties such as flexibility, toughness, and adhesion to different substrates. Modified resins are versatile and can be used in a wide range of applications, including coatings, adhesives, and composite materials. The ability to customize these resins makes them highly valuable in industries where specific performance characteristics are critical. Overall, these three types of low-shrinkage epoxy resins play a crucial role in the Global Low Shrinkage Adhesive Market, providing reliable and high-performance bonding solutions for diverse industrial applications.

Electronics, Aerospace, Automotive, Adhesives, Coatings in the Global Low Shrinkage Adhesive Market:

The usage of Global Low Shrinkage Adhesive Market in various areas such as Electronics, Aerospace, Automotive, Adhesives, and Coatings is extensive and multifaceted. In the electronics industry, low shrinkage adhesives are essential for the assembly and protection of electronic components. They ensure that delicate parts remain securely bonded without any movement or misalignment, which is crucial for the functionality and longevity of electronic devices. These adhesives also provide excellent electrical insulation and resistance to thermal cycling, making them ideal for use in high-performance electronic assemblies. In the aerospace sector, low shrinkage adhesives are used in the manufacturing and maintenance of aircraft components. They offer high strength and durability, which are necessary to withstand the extreme conditions encountered during flight. These adhesives also contribute to weight reduction, which is a critical factor in aerospace engineering. In the automotive industry, low shrinkage adhesives are used for bonding various parts of vehicles, including body panels, interior components, and structural elements. They provide strong and durable bonds that can withstand vibrations, temperature fluctuations, and mechanical stresses. Additionally, these adhesives help in reducing the overall weight of vehicles, contributing to improved fuel efficiency and performance. In the field of adhesives and coatings, low shrinkage adhesives are used to create high-performance bonding solutions for a wide range of applications. They ensure that the bonded materials remain securely attached without any gaps or misalignments, providing reliable and durable bonds. These adhesives are also used in coatings to provide protective layers that enhance the durability and performance of various surfaces. Overall, the usage of low shrinkage adhesives in these areas highlights their importance in ensuring the reliability, durability, and performance of various products and components.

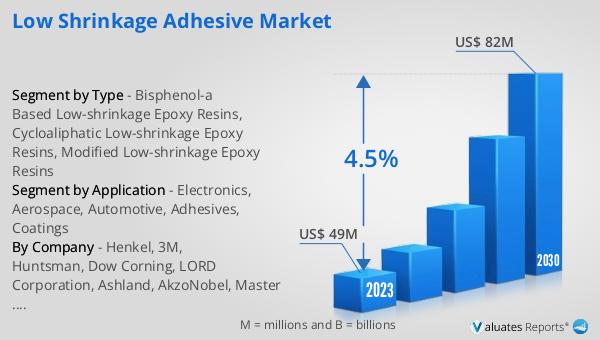

Global Low Shrinkage Adhesive Market Outlook:

The global Low Shrinkage Adhesive market was valued at US$ 49 million in 2023 and is anticipated to reach US$ 82 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for high-performance adhesives across various industries. The projected growth reflects the expanding applications of low shrinkage adhesives in sectors such as electronics, aerospace, automotive, and construction. As industries continue to advance and the need for reliable, durable, and precise bonding solutions grows, the Global Low Shrinkage Adhesive Market is expected to offer innovative solutions to meet the evolving demands of various applications. The market's growth is also supported by ongoing research and development efforts aimed at enhancing the properties and performance of low shrinkage adhesives. These efforts are focused on developing new formulations and technologies that can provide even better bonding solutions for a wide range of industrial applications. Overall, the positive market outlook for low shrinkage adhesives highlights their importance in ensuring the reliability, durability, and performance of various products and components across different industries.

| Report Metric | Details |

| Report Name | Low Shrinkage Adhesive Market |

| Accounted market size in 2023 | US$ 49 million |

| Forecasted market size in 2030 | US$ 82 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Henkel, 3M, Huntsman, Dow Corning, LORD Corporation, Ashland, AkzoNobel, Master Bond, Sika Corporation, Permabond, Robnor ResinLab |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |