What is Global Inspection, Repair and Maintenance (IRM) Service Market?

The Global Inspection, Repair, and Maintenance (IRM) Service Market is a comprehensive industry that focuses on ensuring the optimal functioning and longevity of various assets and infrastructure. This market encompasses a wide range of services, including the inspection of equipment and structures to identify potential issues, the repair of any detected faults, and the maintenance required to prevent future problems. These services are crucial across numerous industries, such as oil and gas, renewable energy, manufacturing, and transportation, where the reliability and safety of equipment are paramount. By providing regular and thorough inspections, the IRM service market helps in minimizing downtime, reducing the risk of accidents, and extending the lifespan of critical assets. This market is driven by the increasing complexity of industrial operations and the growing emphasis on safety and regulatory compliance. As industries continue to evolve and adopt new technologies, the demand for specialized IRM services is expected to rise, making it a vital component of modern industrial operations.

Reactive Maintenance, Preventive Maintenance, Predictive Maintenance, Reliability-Centric Maintenance in the Global Inspection, Repair and Maintenance (IRM) Service Market:

Reactive Maintenance, Preventive Maintenance, Predictive Maintenance, and Reliability-Centric Maintenance are key strategies within the Global Inspection, Repair, and Maintenance (IRM) Service Market. Reactive Maintenance, often referred to as "run-to-failure" maintenance, involves repairing equipment only after it has broken down. This approach can lead to unexpected downtime and higher costs due to emergency repairs and potential damage to other components. However, it is sometimes used for non-critical equipment where the cost of downtime is minimal. Preventive Maintenance, on the other hand, involves regular, scheduled maintenance activities designed to prevent equipment failures before they occur. This strategy includes tasks such as lubrication, adjustments, and parts replacement, which are performed based on a set schedule or usage metrics. Preventive Maintenance helps in reducing the likelihood of unexpected breakdowns and extends the lifespan of equipment. Predictive Maintenance takes a more advanced approach by using data and analytics to predict when equipment is likely to fail. This method involves monitoring the condition of equipment through sensors and other diagnostic tools, allowing maintenance to be performed just in time to prevent failure. Predictive Maintenance can significantly reduce downtime and maintenance costs by addressing issues before they become critical. Reliability-Centric Maintenance (RCM) is a comprehensive approach that combines elements of all the above strategies. RCM focuses on identifying the most critical assets and determining the most effective maintenance strategy for each one. This approach involves a thorough analysis of equipment failure modes and their consequences, allowing organizations to prioritize maintenance activities based on the impact on overall system reliability and safety. By implementing RCM, companies can optimize their maintenance efforts, ensuring that resources are allocated efficiently and effectively. In the context of the Global IRM Service Market, these maintenance strategies are essential for maintaining the reliability and safety of industrial operations. Each strategy has its own advantages and is chosen based on the specific needs and criticality of the equipment involved. As industries continue to adopt more sophisticated technologies and data-driven approaches, the integration of these maintenance strategies will play a crucial role in enhancing operational efficiency and reducing costs.

Oil, Gas, Renewable Energy, Others in the Global Inspection, Repair and Maintenance (IRM) Service Market:

The Global Inspection, Repair, and Maintenance (IRM) Service Market plays a crucial role in various sectors, including oil, gas, renewable energy, and others. In the oil industry, IRM services are essential for ensuring the safety and efficiency of drilling rigs, pipelines, and refineries. Regular inspections help in identifying potential issues such as corrosion, leaks, and structural weaknesses, which can lead to catastrophic failures if left unaddressed. Repair and maintenance activities are carried out to fix these issues and prevent future occurrences, thereby minimizing downtime and ensuring continuous production. In the gas sector, IRM services are equally important for maintaining the integrity of gas pipelines, storage facilities, and processing plants. Inspections help in detecting leaks, pressure anomalies, and other potential hazards, while repair and maintenance activities ensure that these issues are promptly addressed. This not only enhances the safety of gas operations but also helps in complying with stringent regulatory requirements. In the renewable energy sector, IRM services are vital for the upkeep of wind turbines, solar panels, and other renewable energy infrastructure. Regular inspections help in identifying wear and tear, mechanical failures, and other issues that can affect the performance and efficiency of renewable energy systems. Repair and maintenance activities are carried out to ensure that these systems operate at optimal levels, thereby maximizing energy production and reducing downtime. In other industries, such as manufacturing and transportation, IRM services are essential for maintaining the reliability and safety of machinery, equipment, and infrastructure. Regular inspections help in identifying potential issues, while repair and maintenance activities ensure that these issues are promptly addressed. This not only enhances the efficiency of operations but also helps in extending the lifespan of critical assets. Overall, the Global IRM Service Market is indispensable for ensuring the smooth and efficient functioning of various industries. By providing regular inspections, timely repairs, and preventive maintenance, IRM services help in minimizing downtime, reducing the risk of accidents, and extending the lifespan of critical assets. As industries continue to evolve and adopt new technologies, the demand for specialized IRM services is expected to rise, making it a vital component of modern industrial operations.

Global Inspection, Repair and Maintenance (IRM) Service Market Outlook:

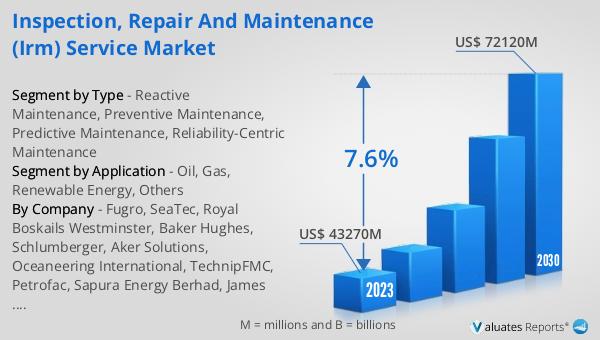

The global Inspection, Repair, and Maintenance (IRM) Service market was valued at $43.27 billion in 2023 and is projected to reach $72.12 billion by 2030, reflecting a compound annual growth rate (CAGR) of 7.6% during the forecast period from 2024 to 2030. This significant growth underscores the increasing importance of IRM services across various industries. As industrial operations become more complex and the emphasis on safety and regulatory compliance intensifies, the demand for comprehensive IRM services is expected to rise. The market's expansion is driven by the need to ensure the reliability and efficiency of critical assets, minimize downtime, and reduce the risk of accidents. With advancements in technology and the adoption of data-driven approaches, the IRM service market is poised to play a crucial role in modern industrial operations. This growth trajectory highlights the essential nature of IRM services in maintaining the optimal functioning and longevity of equipment and infrastructure across diverse sectors.

| Report Metric | Details |

| Report Name | Inspection, Repair and Maintenance (IRM) Service Market |

| Accounted market size in 2023 | US$ 43270 million |

| Forecasted market size in 2030 | US$ 72120 million |

| CAGR | 7.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Fugro, SeaTec, Royal Boskails Westminster, Baker Hughes, Schlumberger, Aker Solutions, Oceaneering International, TechnipFMC, Petrofac, Sapura Energy Berhad, James Fisher Offshore, Bluestrean Offshore B.V, Helix Energy Solutions, RockSalt Subsea, Acteon, Rana Diving, Qualitech, Cotech IRM Services, ACSM Ships, Elberd Engineering, KOTUG International, TAG Energy, Phoenix International, DOF Subsea, Sapura Energy |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |