What is Global Hydraulic Headbox Market?

The Global Hydraulic Headbox Market is a specialized segment within the broader industrial machinery market, focusing on equipment used in the paper and pulp industry. A hydraulic headbox is a crucial component in the papermaking process, responsible for distributing the pulp slurry uniformly across the width of the paper machine. This uniform distribution is essential for producing high-quality paper with consistent thickness and properties. The hydraulic headbox operates by using a combination of water and air pressure to control the flow and spread of the pulp. This technology has evolved over the years to include advanced features such as automated controls and precision engineering, making it indispensable for modern papermaking. The market for hydraulic headboxes is driven by the increasing demand for paper and paperboard products, technological advancements, and the need for efficient and high-quality production processes. As industries continue to seek ways to improve productivity and reduce waste, the adoption of advanced hydraulic headboxes is expected to grow.

With Dilution, Without Dilution in the Global Hydraulic Headbox Market:

In the Global Hydraulic Headbox Market, there are two primary types of headboxes: with dilution and without dilution. A hydraulic headbox with dilution is designed to allow for the addition of water to the pulp slurry during the papermaking process. This dilution process helps in achieving better control over the fiber distribution and consistency of the paper. The dilution water is added through a series of valves and nozzles, which are precisely controlled to ensure uniform distribution. This type of headbox is particularly useful in producing high-quality paper grades where uniformity and consistency are critical. On the other hand, a hydraulic headbox without dilution does not incorporate the addition of water during the process. Instead, it relies solely on the mechanical action of the headbox to distribute the pulp slurry. This type of headbox is typically used in applications where the paper quality requirements are less stringent, or where the production process does not necessitate the additional control provided by dilution. Both types of headboxes have their own advantages and are chosen based on the specific needs of the papermaking process. The choice between a headbox with dilution and one without dilution depends on various factors such as the type of paper being produced, the desired quality, and the specific requirements of the production process. For instance, high-quality writing and printing papers often require the use of a headbox with dilution to achieve the necessary uniformity and consistency. In contrast, packaging papers and other lower-grade papers may be produced using a headbox without dilution. The technological advancements in hydraulic headboxes have also led to the development of hybrid systems that can switch between dilution and non-dilution modes, offering greater flexibility and efficiency in the papermaking process. These hybrid systems are gaining popularity as they provide the benefits of both types of headboxes, allowing manufacturers to optimize their production processes based on the specific requirements of each paper grade. The global market for hydraulic headboxes is witnessing significant growth due to the increasing demand for high-quality paper products, technological advancements, and the need for efficient production processes. As industries continue to seek ways to improve productivity and reduce waste, the adoption of advanced hydraulic headboxes, both with and without dilution, is expected to grow.

Paper, Board, Others in the Global Hydraulic Headbox Market:

The usage of hydraulic headboxes in the Global Hydraulic Headbox Market spans across various applications, including paper, board, and other products. In the paper industry, hydraulic headboxes are essential for producing a wide range of paper grades, from high-quality writing and printing papers to specialty papers such as tissue and filter papers. The uniform distribution of pulp slurry achieved by hydraulic headboxes ensures that the paper produced has consistent thickness, strength, and other properties. This is particularly important for high-quality papers where any variation in thickness or fiber distribution can significantly impact the final product. In the board industry, hydraulic headboxes are used to produce different types of paperboard, including containerboard, folding boxboard, and solid bleached board. These products are used in various packaging applications, from corrugated boxes to high-end packaging for consumer goods. The use of hydraulic headboxes in the production of paperboard ensures that the final product has the necessary strength, durability, and printability required for packaging applications. The ability to control the fiber distribution and consistency of the paperboard is crucial for meeting the stringent quality standards of the packaging industry. Beyond paper and board, hydraulic headboxes are also used in the production of other products such as nonwoven materials and specialty papers. Nonwoven materials, which are used in applications such as hygiene products, medical supplies, and industrial filters, require precise control over the fiber distribution to achieve the desired properties. Hydraulic headboxes provide the necessary control and uniformity to produce high-quality nonwoven materials. Similarly, specialty papers, which are used in applications such as currency, security documents, and technical papers, require precise control over the fiber distribution and consistency. The use of hydraulic headboxes in the production of these specialty papers ensures that the final product meets the specific requirements of each application. The versatility and precision offered by hydraulic headboxes make them indispensable in the production of a wide range of paper and paperboard products. As the demand for high-quality paper and paperboard products continues to grow, the usage of hydraulic headboxes in these applications is expected to increase. The ongoing advancements in hydraulic headbox technology, including the development of hybrid systems and automated controls, are further enhancing their capabilities and efficiency, making them a critical component in the modern papermaking process.

Global Hydraulic Headbox Market Outlook:

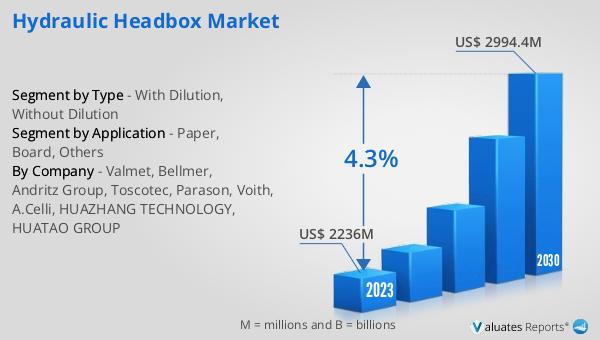

The global Hydraulic Headbox market was valued at US$ 2236 million in 2023 and is anticipated to reach US$ 2994.4 million by 2030, witnessing a CAGR of 4.3% during the forecast period 2024-2030. This growth is driven by the increasing demand for high-quality paper and paperboard products, technological advancements in hydraulic headbox design, and the need for efficient and sustainable production processes. The market is characterized by the presence of several key players who are continuously investing in research and development to enhance the performance and capabilities of hydraulic headboxes. These advancements include the development of hybrid systems that can switch between dilution and non-dilution modes, automated controls for precise fiber distribution, and the use of advanced materials to improve durability and efficiency. The growing emphasis on sustainability and reducing environmental impact is also driving the adoption of advanced hydraulic headboxes, as they enable more efficient use of raw materials and reduce waste. As industries continue to seek ways to improve productivity and meet the increasing demand for high-quality paper products, the global Hydraulic Headbox market is expected to witness significant growth in the coming years.

| Report Metric | Details |

| Report Name | Hydraulic Headbox Market |

| Accounted market size in 2023 | US$ 2236 million |

| Forecasted market size in 2030 | US$ 2994.4 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Valmet, Bellmer, Andritz Group, Toscotec, Parason, Voith, A.Celli, HUAZHANG TECHNOLOGY, HUATAO GROUP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |