What is Global High Temperature Resistant Fiber Coating Market?

The global high temperature resistant fiber coating market is a specialized segment within the broader coatings industry. This market focuses on the development and application of coatings that can withstand extremely high temperatures, making them suitable for use in harsh environments where conventional coatings would fail. These coatings are primarily used to protect fibers that are exposed to high temperatures, ensuring their durability and performance in various industrial applications. The demand for high temperature resistant fiber coatings is driven by industries such as aerospace, automotive, and energy, where materials are often subjected to extreme conditions. The coatings not only provide thermal protection but also enhance the mechanical properties of the fibers, such as tensile strength and resistance to abrasion. As industries continue to push the boundaries of material performance, the need for advanced coatings that can endure high temperatures is expected to grow, making this market a critical area of focus for innovation and development.

Primary Fiber Coating, Secondary Fiber Coating in the Global High Temperature Resistant Fiber Coating Market:

Primary fiber coating and secondary fiber coating are two essential components in the global high temperature resistant fiber coating market. Primary fiber coating is the initial layer applied directly to the fiber, serving as the first line of defense against high temperatures and environmental factors. This coating is crucial for maintaining the integrity of the fiber, preventing damage from heat, moisture, and chemical exposure. It also plays a significant role in enhancing the fiber's mechanical properties, such as flexibility and tensile strength. Primary coatings are typically made from materials like polyimide, which can withstand temperatures up to 400°C, making them ideal for high-performance applications in industries like aerospace and automotive. On the other hand, secondary fiber coating is applied over the primary coating, providing an additional layer of protection and enhancing the overall performance of the fiber. This coating is designed to offer improved resistance to abrasion, UV radiation, and other environmental factors that could degrade the fiber over time. Secondary coatings are often made from materials like silicone or polyacrylate, which provide excellent thermal stability and durability. The combination of primary and secondary coatings ensures that the fibers can perform reliably in extreme conditions, extending their lifespan and reducing maintenance costs. In the global high temperature resistant fiber coating market, the interplay between primary and secondary coatings is critical for achieving the desired performance characteristics. Manufacturers invest heavily in research and development to create coatings that can meet the stringent requirements of various industries. This involves not only selecting the right materials but also optimizing the application processes to ensure uniform coverage and adhesion. Advanced techniques such as plasma-enhanced chemical vapor deposition (PECVD) and sol-gel processes are often used to apply these coatings, providing precise control over thickness and composition. The development of high temperature resistant fiber coatings is a complex and multidisciplinary field, requiring expertise in materials science, chemistry, and engineering. As industries continue to demand higher performance from their materials, the importance of primary and secondary fiber coatings will only increase. These coatings not only protect the fibers but also enable them to function in environments that would otherwise be too harsh, opening up new possibilities for innovation and application.

Polyimide Coating Fiber, High Temperature Resistant Polyacrylate Coating Fiber, Silicone Coating Fiber, Others in the Global High Temperature Resistant Fiber Coating Market:

The global high temperature resistant fiber coating market finds extensive usage in various specialized areas, including polyimide coating fiber, high temperature resistant polyacrylate coating fiber, silicone coating fiber, and others. Polyimide coating fiber is renowned for its exceptional thermal stability, capable of withstanding temperatures up to 400°C. This makes it an ideal choice for applications in aerospace, where materials are often exposed to extreme heat and require high performance. Polyimide coatings provide excellent mechanical properties, such as high tensile strength and flexibility, ensuring that the fibers can endure the rigorous demands of aerospace applications. High temperature resistant polyacrylate coating fiber, on the other hand, offers a unique combination of thermal stability and chemical resistance. These coatings are particularly useful in the automotive industry, where fibers need to withstand not only high temperatures but also exposure to various chemicals and fuels. Polyacrylate coatings enhance the durability and longevity of the fibers, reducing the need for frequent replacements and maintenance. Silicone coating fiber is another critical area within the high temperature resistant fiber coating market. Silicone coatings are known for their excellent thermal stability, flexibility, and resistance to environmental factors such as UV radiation and moisture. These properties make silicone-coated fibers suitable for a wide range of applications, including electrical insulation and protective clothing. The flexibility of silicone coatings allows the fibers to maintain their performance even under dynamic conditions, making them ideal for use in environments where materials are subjected to constant movement and stress. In addition to these specific types of coatings, the global high temperature resistant fiber coating market also includes other specialized coatings designed for niche applications. These may include coatings made from materials like ceramic or metal oxides, which offer unique properties such as extreme thermal resistance and electrical conductivity. These specialized coatings are often used in industries like energy and electronics, where materials need to perform reliably under extreme conditions. The versatility and performance of high temperature resistant fiber coatings make them indispensable in various industrial applications. As technology continues to advance, the demand for these coatings is expected to grow, driving further innovation and development in the market.

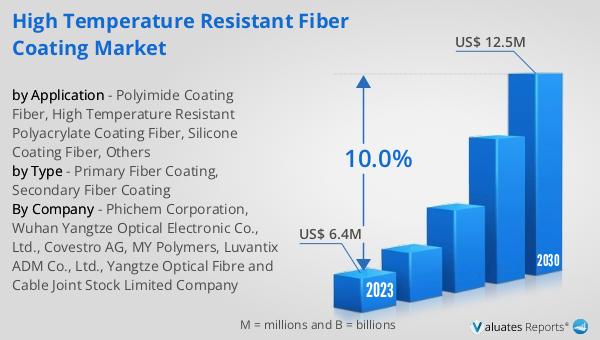

Global High Temperature Resistant Fiber Coating Market Outlook:

The global high temperature resistant fiber coating market was valued at US$ 6.4 million in 2023 and is anticipated to reach US$ 12.5 million by 2030, witnessing a CAGR of 10.0% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-performance materials that can withstand extreme conditions across various industries. The market's expansion is driven by advancements in coating technologies and the growing need for durable and reliable materials in sectors such as aerospace, automotive, and energy. As industries continue to push the boundaries of material performance, the importance of high temperature resistant fiber coatings is expected to rise, making this market a critical area of focus for innovation and development. The projected growth rate underscores the market's potential and the ongoing efforts by manufacturers to develop advanced coatings that meet the stringent requirements of modern industrial applications.

| Report Metric | Details |

| Report Name | High Temperature Resistant Fiber Coating Market |

| Accounted market size in 2023 | US$ 6.4 million |

| Forecasted market size in 2030 | US$ 12.5 million |

| CAGR | 10.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Phichem Corporation, Wuhan Yangtze Optical Electronic Co., Ltd., Covestro AG, MY Polymers, Luvantix ADM Co., Ltd., Yangtze Optical Fibre and Cable Joint Stock Limited Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |