What is Global Grinding Media Market?

The Global Grinding Media Market refers to the industry that produces and sells grinding media, which are materials used to crush or grind other materials in various industrial processes. Grinding media can be made from a variety of materials, including steel, ceramics, and other alloys. These materials are essential in industries such as mining, metallurgy, cement, and power plants, where they are used to break down ores, minerals, and other raw materials into smaller, more manageable pieces. The market is driven by the demand for these industries to increase efficiency and reduce operational costs. As industries continue to grow and evolve, the need for high-quality grinding media becomes even more critical. The market is also influenced by technological advancements, which lead to the development of more durable and efficient grinding media. Overall, the Global Grinding Media Market plays a crucial role in supporting various industrial processes by providing the necessary materials to enhance productivity and efficiency.

Forged Grinding Media, High Chrome Cast Grinding Media, Other Cast Grinding Media in the Global Grinding Media Market:

Forged Grinding Media, High Chrome Cast Grinding Media, and Other Cast Grinding Media are three primary types of grinding media used in the Global Grinding Media Market. Forged Grinding Media is made by heating steel and then shaping it into balls or other forms through a forging process. This type of grinding media is known for its high impact resistance and durability, making it ideal for use in heavy-duty industrial applications such as mining and metallurgy. The forging process ensures that the media has a uniform structure, which enhances its performance and longevity. High Chrome Cast Grinding Media, on the other hand, is produced by casting molten metal into molds to create balls or other shapes. This type of grinding media contains a high percentage of chromium, which gives it excellent wear resistance and hardness. High Chrome Cast Grinding Media is particularly suitable for use in cement and power plants, where the grinding process involves high levels of abrasion and impact. The high chromium content also provides superior corrosion resistance, making it a preferred choice in environments where the media is exposed to harsh chemicals or moisture. Other Cast Grinding Media includes a variety of cast materials that do not fall into the high chrome category. These can include low chrome cast grinding media, which has a lower chromium content but still offers good wear resistance and durability. Other Cast Grinding Media is often used in applications where the grinding process is less demanding, or where cost considerations are a primary concern. Each type of grinding media has its own unique properties and advantages, making them suitable for different industrial applications. The choice of grinding media depends on factors such as the material being ground, the grinding process, and the specific requirements of the industry. By understanding the characteristics and benefits of each type of grinding media, industries can select the most appropriate media to optimize their grinding processes and improve overall efficiency.

Mining and Metallurgy, Cement, Power Plant, Others in the Global Grinding Media Market:

The Global Grinding Media Market finds extensive usage in various industries, including Mining and Metallurgy, Cement, Power Plant, and others. In the Mining and Metallurgy sector, grinding media is used to crush and grind ores and minerals to extract valuable metals and minerals. The grinding process is a critical step in the extraction and processing of metals such as gold, silver, copper, and iron. High-quality grinding media ensures that the ores are ground to the desired size, which enhances the efficiency of the extraction process and improves the overall yield. In the Cement industry, grinding media is used to grind raw materials such as limestone, clay, and gypsum to produce cement. The grinding process is essential in achieving the desired fineness and consistency of the cement, which directly impacts the quality and performance of the final product. High Chrome Cast Grinding Media is particularly popular in the cement industry due to its excellent wear resistance and durability, which helps to reduce operational costs and improve productivity. In Power Plants, grinding media is used in coal pulverizers to grind coal into a fine powder, which is then used as fuel for generating electricity. The grinding process is crucial in ensuring that the coal is ground to the appropriate size for efficient combustion. High-quality grinding media helps to improve the efficiency of the pulverizers and reduce maintenance costs. Other industries that use grinding media include chemical processing, where grinding media is used to grind chemicals and other materials to achieve the desired particle size and consistency. The choice of grinding media in these industries depends on factors such as the material being ground, the grinding process, and the specific requirements of the industry. By selecting the appropriate grinding media, industries can optimize their grinding processes, improve efficiency, and reduce operational costs.

Global Grinding Media Market Outlook:

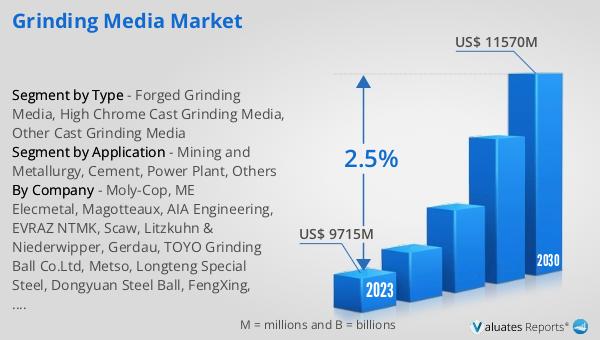

The global Grinding Media market is anticipated to expand from US$ 9978.5 million in 2024 to US$ 11570 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 2.5% over the forecast period. The market is dominated by the top four manufacturers, who collectively hold nearly 25% of the market share. Among the various product types, High Chrome Cast Grinding Media stands out as the largest segment, accounting for over 45% of the market share. This segment's prominence can be attributed to its superior wear resistance, hardness, and durability, making it a preferred choice in industries such as cement and power plants. The high chromium content in this type of grinding media provides excellent corrosion resistance, which is particularly beneficial in harsh industrial environments. The market's growth is driven by the increasing demand for efficient and durable grinding media in various industrial applications. As industries continue to evolve and seek ways to improve productivity and reduce operational costs, the demand for high-quality grinding media is expected to rise. Technological advancements in the production of grinding media are also contributing to the market's growth, as they lead to the development of more efficient and durable products. Overall, the Global Grinding Media Market is poised for steady growth, supported by the increasing demand from various industries and the continuous advancements in grinding media technology.

| Report Metric | Details |

| Report Name | Grinding Media Market |

| Accounted market size in 2024 | US$ 9978.5 million |

| Forecasted market size in 2030 | US$ 11570 million |

| CAGR | 2.5 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Moly-Cop, ME Elecmetal, Magotteaux, AIA Engineering, EVRAZ NTMK, Scaw, Litzkuhn & Niederwipper, Gerdau, TOYO Grinding Ball Co.Ltd, Metso, Longteng Special Steel, Dongyuan Steel Ball, FengXing, Shandong Huamin, Anhui Ruitai, Jianzhen Steel Ball, Oriental Casting and Forging, Jinan Huafu, Zhengxing Grinding Ball, Jinan Daming New Material, Sheng Ye Grinding Ball, Jinchi Steel Ball |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |