What is Global Electroless Plating Market?

The Global Electroless Plating Market refers to the industry focused on the application of a metal coating on a substrate without using an electric current. This process, known as electroless plating, involves a chemical reaction that deposits a metal layer onto a material, typically to enhance its properties such as corrosion resistance, hardness, and wear resistance. The market encompasses various types of electroless plating, including nickel, copper, and composite coatings, each serving different industrial needs. The demand for electroless plating is driven by its advantages over traditional electroplating, such as uniform coating thickness and the ability to plate non-conductive materials. Industries like automotive, electronics, aerospace, and oil and gas heavily rely on electroless plating for improving the durability and performance of their components. The market is expanding globally, with significant contributions from regions like Asia-Pacific, Europe, and North America. The growth is attributed to technological advancements, increasing industrial applications, and the rising need for high-performance materials.

Medium-phosphorus Electroless Nickel, Low-phosphorus Electroless Nickel, High-phosphorus Electroless Nickel, Electroless Copper, Electroless Composites in the Global Electroless Plating Market:

Medium-phosphorus electroless nickel plating is widely used due to its balanced properties, offering good corrosion resistance and hardness. It is commonly applied in industries such as automotive, electronics, and machinery, where these attributes are crucial. Low-phosphorus electroless nickel plating, on the other hand, is known for its superior hardness and wear resistance, making it ideal for applications that require high durability, such as in the oil and gas industry. High-phosphorus electroless nickel plating provides excellent corrosion resistance, especially in harsh environments, and is often used in chemical processing and marine applications. Electroless copper plating is primarily used in the electronics industry for printed circuit boards (PCBs) and other electronic components, as it offers excellent electrical conductivity and solderability. Electroless composites, which involve the co-deposition of particles such as PTFE, silicon carbide, or diamond with the metal matrix, are used to enhance specific properties like lubricity, wear resistance, and thermal conductivity. These composites find applications in various high-performance industries, including aerospace, automotive, and industrial machinery. The versatility and adaptability of electroless plating make it a preferred choice for many industrial applications, driving the growth of the global electroless plating market.

Automotive Industrial, Chemical Industrial, Oil Industrial, Electronics Industrial, Aerospace Industrial, Machinery Industrial, Others in the Global Electroless Plating Market:

The global electroless plating market finds extensive usage across various industries due to its ability to provide uniform coatings with enhanced properties. In the automotive industry, electroless plating is used to improve the durability and performance of components such as fuel injectors, pistons, and gears. The corrosion resistance and wear resistance offered by electroless nickel plating, in particular, are highly valued in this sector. In the chemical industry, electroless plating is used to protect equipment and components from corrosive chemicals, thereby extending their lifespan and reducing maintenance costs. The oil industry also benefits from electroless plating, especially in downhole tools and equipment that are exposed to harsh environments. The electronics industry relies heavily on electroless copper plating for the production of printed circuit boards (PCBs) and other electronic components, as it provides excellent electrical conductivity and solderability. In the aerospace industry, electroless plating is used to enhance the performance and reliability of critical components, such as landing gear and hydraulic systems, by providing superior corrosion resistance and wear resistance. The machinery industry uses electroless plating to improve the performance and longevity of various machine parts, including shafts, bearings, and valves. Other industries, such as medical devices and telecommunications, also utilize electroless plating for its ability to provide high-quality, durable coatings. The widespread application of electroless plating across these diverse industries underscores its importance and drives the growth of the global electroless plating market.

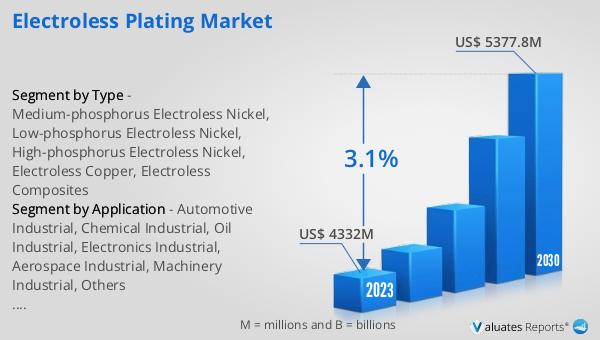

Global Electroless Plating Market Outlook:

The global electroless plating market is anticipated to expand from $4,477.7 million in 2024 to $5,377.8 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 3.1% over the forecast period. The top four global manufacturers collectively hold nearly 15% of the market share. The Asia-Pacific region is the largest market, accounting for approximately 40% of the total share, followed by Europe and North America, which together hold over 50% of the market share. Among the various products, low-phosphorus electroless nickel is the largest segment, representing over 60% of the market.

| Report Metric | Details |

| Report Name | Electroless Plating Market |

| Accounted market size in 2024 | US$ 4477.7 million |

| Forecasted market size in 2030 | US$ 5377.8 million |

| CAGR | 3.1 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | MacDermid, Atotech, Aalberts Surface Treatment, UYEMURA, Collini, Japan Kanigen, Okuno chemical industries, Coventya, TANAKA(EEJA), Q & M Enterprises, Argos SpA, Thermocompact, KC Jones Plating Company, Micron srl, PacTech, Ensoo, GS Chemistry, Shenzhen Success, Advanced Surface Technologies, NiTEC, HLHC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |