What is Global Double Station Extrusion Blow Molding Machine Market?

The Global Double Station Extrusion Blow Molding Machine Market refers to the worldwide industry focused on the production and sale of machines designed for extrusion blow molding processes. These machines are specifically engineered to create hollow plastic products by extruding a tube of molten plastic, known as a parison, and then inflating it within a mold to form the desired shape. The "double station" aspect indicates that these machines have two stations, allowing for simultaneous production, which enhances efficiency and output. This market encompasses a wide range of applications, including packaging for food and beverages, pharmaceuticals, cosmetics, and personal care products. The demand for these machines is driven by the need for high-quality, durable, and cost-effective plastic containers and products across various industries. As technology advances, the market continues to evolve, offering more sophisticated and efficient machines to meet the growing demands of manufacturers worldwide.

Continuous Extrusion Blow Moulding, Intermittent Extrusion Blow Moulding in the Global Double Station Extrusion Blow Molding Machine Market:

Continuous Extrusion Blow Molding and Intermittent Extrusion Blow Molding are two primary methods used in the Global Double Station Extrusion Blow Molding Machine Market. Continuous Extrusion Blow Molding involves the constant extrusion of the parison, which is then cut to the desired length and molded. This method is highly efficient and suitable for high-volume production, making it ideal for industries that require large quantities of uniform products, such as beverage bottles and household containers. The continuous process ensures a steady flow of production, reducing downtime and increasing overall productivity. On the other hand, Intermittent Extrusion Blow Molding involves the periodic extrusion of the parison, which is then molded in batches. This method is more flexible and allows for the production of a wider variety of shapes and sizes, making it suitable for specialized applications such as pharmaceutical containers and cosmetic bottles. The intermittent process provides greater control over the molding parameters, allowing for the production of complex and intricate designs. Both methods have their unique advantages and are chosen based on the specific requirements of the product being manufactured. The Global Double Station Extrusion Blow Molding Machine Market caters to both methods, offering machines that can handle continuous and intermittent processes with equal efficiency. These machines are designed to provide high precision, consistency, and reliability, ensuring that manufacturers can meet the stringent quality standards of their respective industries. As the market continues to grow, advancements in technology are leading to the development of more sophisticated machines that offer enhanced capabilities, such as multi-layer extrusion and in-mold labeling. These innovations are helping manufacturers to stay competitive and meet the evolving demands of their customers.

Food and Beverage, Pharmaceutical, Cosmetic and Personal Care, Others in the Global Double Station Extrusion Blow Molding Machine Market:

The usage of Global Double Station Extrusion Blow Molding Machines spans across various industries, including Food and Beverage, Pharmaceutical, Cosmetic and Personal Care, and others. In the Food and Beverage industry, these machines are used to produce a wide range of packaging solutions, such as bottles for water, juices, and dairy products. The ability to produce high-quality, lightweight, and durable containers makes these machines an essential part of the packaging process. In the Pharmaceutical industry, the precision and consistency offered by these machines are crucial for producing containers that meet stringent regulatory standards. These machines are used to manufacture bottles for liquid medications, syringes, and other medical devices, ensuring that the products are safe and reliable. In the Cosmetic and Personal Care industry, the flexibility of these machines allows for the production of a variety of shapes and sizes, catering to the diverse needs of the market. From shampoo bottles to lotion containers, these machines provide the versatility needed to create attractive and functional packaging. Other industries, such as automotive and household products, also benefit from the capabilities of these machines. For example, they are used to produce fuel tanks, oil containers, and cleaning product bottles. The Global Double Station Extrusion Blow Molding Machine Market continues to expand as manufacturers seek efficient and cost-effective solutions for their packaging needs. The advancements in technology and the increasing demand for high-quality plastic products are driving the growth of this market, making it an integral part of the global manufacturing landscape.

Global Double Station Extrusion Blow Molding Machine Market Outlook:

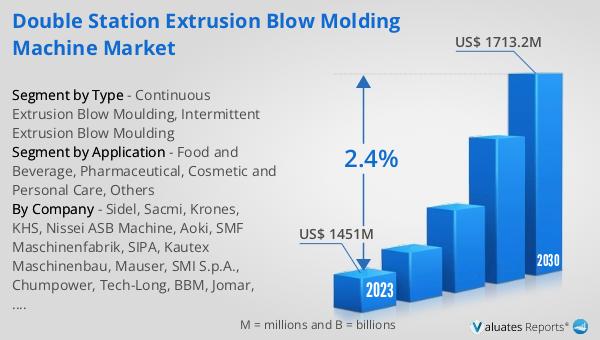

The global Double Station Extrusion Blow Molding Machine market was valued at US$ 1451 million in 2023 and is anticipated to reach US$ 1713.2 million by 2030, witnessing a CAGR of 2.4% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory, driven by the increasing demand for efficient and high-quality extrusion blow molding machines across various industries. The projected growth reflects the market's resilience and adaptability to evolving industry needs and technological advancements. As manufacturers continue to seek innovative solutions to enhance their production processes, the demand for double station extrusion blow molding machines is expected to rise. These machines offer significant advantages in terms of productivity, precision, and versatility, making them a preferred choice for many industries. The market's growth is also supported by the expanding applications of these machines in sectors such as food and beverage, pharmaceuticals, cosmetics, and personal care. The ability to produce a wide range of plastic products with high efficiency and consistency is a key factor driving the market's expansion. As the market continues to evolve, manufacturers are likely to invest in advanced technologies and equipment to stay competitive and meet the growing demands of their customers.

| Report Metric | Details |

| Report Name | Double Station Extrusion Blow Molding Machine Market |

| Accounted market size in 2023 | US$ 1451 million |

| Forecasted market size in 2030 | US$ 1713.2 million |

| CAGR | 2.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sidel, Sacmi, Krones, KHS, Nissei ASB Machine, Aoki, SMF Maschinenfabrik, SIPA, Kautex Maschinenbau, Mauser, SMI S.p.A., Chumpower, Tech-Long, BBM, Jomar, Parker, ZQ Machinery, Bekum, Plastiblow |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |