What is Global Cold Forging Machine Market?

The Global Cold Forging Machine Market refers to the industry that manufactures and sells machines used for cold forging, a process where metal is shaped at room temperature using high pressure. These machines are essential in producing high-strength, precision components for various industries. Cold forging is preferred over hot forging for its ability to produce parts with superior surface finish and dimensional accuracy. The market includes a range of machines designed for different applications and industries, such as automotive, electronics, machinery, construction, and aviation. The demand for cold forging machines is driven by the need for durable and high-quality components, as well as the growing emphasis on cost-effective manufacturing processes. The market is characterized by technological advancements, increasing automation, and the development of more efficient and versatile machines. Companies in this market are continuously innovating to meet the evolving needs of their customers and to stay competitive.

3-Die Station, 1-Die Station, 2-Die Station, 4-Die Station, 5-Die Station, 6-Die Station, 7-Die Station in the Global Cold Forging Machine Market:

In the Global Cold Forging Machine Market, various types of die stations are used, each serving a specific purpose and offering unique advantages. A 1-Die Station machine is the simplest form, typically used for basic forging operations where a single die is sufficient to shape the metal. These machines are ideal for small-scale production and simpler components. A 2-Die Station machine, on the other hand, allows for more complex shapes and higher precision, as it uses two dies to progressively shape the metal. This type is commonly used in medium-scale production where slightly more intricate parts are required. Moving up, a 3-Die Station machine offers even greater complexity and precision, suitable for producing parts with more detailed geometries. These machines are often used in industries where high accuracy is crucial. A 4-Die Station machine takes this a step further, providing the capability to produce highly complex parts with multiple stages of shaping. This type is particularly useful in high-volume production environments where consistency and precision are paramount. The 5-Die Station machine is one of the most versatile, capable of handling a wide range of shapes and sizes. It is often used in the automotive industry for producing critical components like gears and shafts. A 6-Die Station machine offers even more versatility and is designed for extremely high-precision applications. These machines are used in industries where the highest levels of accuracy and surface finish are required. Finally, the 7-Die Station machine represents the pinnacle of cold forging technology, capable of producing the most complex and precise parts. These machines are used in specialized applications where no compromise on quality is acceptable. Each type of die station machine plays a crucial role in the Global Cold Forging Machine Market, catering to the diverse needs of various industries and applications.

Automotive Industry, Electric & Electronics, Machinery Industry, Construction Industry, Aviation, Others in the Global Cold Forging Machine Market:

The Global Cold Forging Machine Market finds extensive usage across several key industries, each benefiting from the unique advantages of cold forging technology. In the automotive industry, cold forging machines are used to produce high-strength, precision components such as gears, shafts, and fasteners. These parts are critical for the performance and safety of vehicles, and cold forging ensures they meet the stringent quality standards required. The electric and electronics industry also relies heavily on cold forging machines to manufacture components like connectors, terminals, and heat sinks. These parts need to be highly precise and durable to ensure the reliability of electronic devices. In the machinery industry, cold forging is used to produce a wide range of components, from simple fasteners to complex gears and bearings. The high strength and precision of cold-forged parts make them ideal for use in heavy machinery and industrial equipment. The construction industry benefits from cold forging machines in the production of structural components, fasteners, and other hardware. These parts need to be strong and durable to withstand the harsh conditions of construction sites. In the aviation industry, cold forging is used to produce critical components such as turbine blades, landing gear parts, and fasteners. The high precision and strength of cold-forged parts are essential for the safety and performance of aircraft. Other industries, such as medical devices and consumer goods, also utilize cold forging machines to produce high-quality, durable components. The versatility and efficiency of cold forging make it a preferred manufacturing process across a wide range of applications.

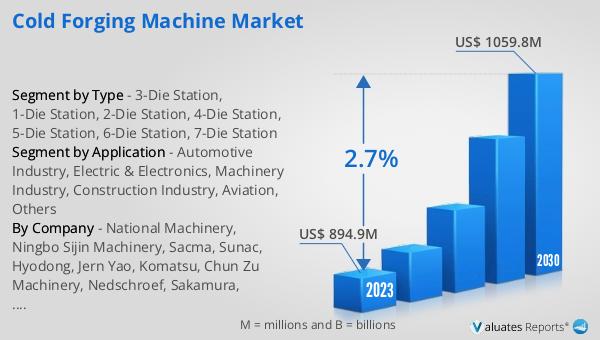

Global Cold Forging Machine Market Outlook:

The global Cold Forging Machine market is anticipated to expand from US$ 904.8 million in 2024 to US$ 1059.8 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 2.7% during the forecast period. The market is dominated by the top five players, who collectively hold about 40% of the market share. Among the various product types, the 5-Die Station segment is the largest, accounting for approximately 22% of the market. In terms of application, the automotive industry is the leading segment, with a share of about 24%. This growth is driven by the increasing demand for high-strength, precision components in various industries, as well as the continuous advancements in cold forging technology. Companies in this market are focusing on innovation and efficiency to meet the evolving needs of their customers and to maintain their competitive edge.

| Report Metric | Details |

| Report Name | Cold Forging Machine Market |

| Accounted market size in 2024 | US$ 904.8 million |

| Forecasted market size in 2030 | US$ 1059.8 million |

| CAGR | 2.7 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | National Machinery, Ningbo Sijin Machinery, Sacma, Sunac, Hyodong, Jern Yao, Komatsu, Chun Zu Machinery, Nedschroef, Sakamura, Hatebur, Nakashimada, Aida, Dongrui Machinery, Chin Fong Machine, Qunfeng Machinery, Yeswin Machinery, GFM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |