What is Global Biopharma Freeze Dryer Machine Market?

The Global Biopharma Freeze Dryer Machine Market is a specialized segment within the broader pharmaceutical and biotechnology equipment industry. These machines are essential for the lyophilization process, which involves freezing a product and then reducing the surrounding pressure to allow the frozen water in the product to sublimate directly from the solid phase to the gas phase. This process is crucial for preserving the integrity and stability of biopharmaceutical products, such as vaccines, antibodies, and other biologics. The market for these machines is driven by the increasing demand for biopharmaceuticals, advancements in freeze-drying technology, and the need for efficient and reliable preservation methods. The machines are used in various settings, including research laboratories, pharmaceutical manufacturing facilities, and other specialized environments. The global market is characterized by a range of products, from small-scale laboratory units to large industrial systems, catering to different needs and capacities. The growth of this market is also influenced by regulatory requirements and the need for high-quality, consistent production processes in the biopharmaceutical industry.

Single Stage Refrigeration Compression Cycle, Two-stage Refrigeration Compression Cycle in the Global Biopharma Freeze Dryer Machine Market:

The Single Stage Refrigeration Compression Cycle and Two-stage Refrigeration Compression Cycle are two critical technologies used in the Global Biopharma Freeze Dryer Machine Market. The Single Stage Refrigeration Compression Cycle is a simpler system that uses a single compressor to circulate refrigerant through the system. This cycle involves four main processes: compression, condensation, expansion, and evaporation. In the compression phase, the refrigerant gas is compressed, raising its temperature and pressure. It then moves to the condenser, where it releases heat and condenses into a liquid. The liquid refrigerant then passes through an expansion valve, where it undergoes a pressure drop and cools down. Finally, in the evaporation phase, the refrigerant absorbs heat from the surroundings, causing it to evaporate and return to the compressor as a low-pressure gas. This cycle is efficient for smaller freeze-drying applications and is commonly used in laboratory-scale freeze dryers. On the other hand, the Two-stage Refrigeration Compression Cycle is more complex and involves two compressors working in tandem. This system is designed to achieve lower temperatures and higher efficiency, making it suitable for larger industrial freeze-drying applications. The two-stage cycle also involves four main processes, but with an additional intermediate cooling stage. In the first stage, the refrigerant gas is compressed by the first compressor, raising its temperature and pressure. It then moves to the first condenser, where it releases some heat and partially condenses. The partially condensed refrigerant then passes through an intercooler, where it is further cooled before entering the second compressor. The second compressor further compresses the refrigerant, raising its temperature and pressure even higher. The refrigerant then moves to the second condenser, where it releases more heat and fully condenses into a liquid. The liquid refrigerant then passes through an expansion valve, where it undergoes a pressure drop and cools down. Finally, in the evaporation phase, the refrigerant absorbs heat from the surroundings, causing it to evaporate and return to the first compressor as a low-pressure gas. This cycle is more efficient for larger freeze-drying applications and is commonly used in industrial-scale freeze dryers. Both the Single Stage and Two-stage Refrigeration Compression Cycles have their advantages and disadvantages. The Single Stage cycle is simpler, more cost-effective, and easier to maintain, making it suitable for smaller applications. However, it may not achieve the low temperatures and high efficiency required for larger industrial applications. The Two-stage cycle, on the other hand, is more complex and expensive, but it can achieve lower temperatures and higher efficiency, making it suitable for larger industrial applications. The choice between the two cycles depends on the specific requirements of the freeze-drying application, including the size of the system, the desired temperature range, and the efficiency requirements. In the Global Biopharma Freeze Dryer Machine Market, both Single Stage and Two-stage Refrigeration Compression Cycles play a crucial role in ensuring the efficiency and reliability of the freeze-drying process. The choice of cycle depends on the specific needs of the application, with smaller laboratory-scale freeze dryers typically using Single Stage cycles and larger industrial-scale freeze dryers using Two-stage cycles. As the demand for biopharmaceutical products continues to grow, the need for efficient and reliable freeze-drying technologies will also increase, driving the development and adoption of advanced refrigeration compression cycles in the market.

Biology Laboratory, Pharmaceutical Factory, Others in the Global Biopharma Freeze Dryer Machine Market:

The Global Biopharma Freeze Dryer Machine Market finds extensive usage in various areas, including Biology Laboratories, Pharmaceutical Factories, and other specialized environments. In Biology Laboratories, freeze dryers are essential for preserving biological samples, such as cells, tissues, and microorganisms. The lyophilization process helps maintain the integrity and stability of these samples, allowing researchers to store them for extended periods without compromising their quality. Freeze dryers in biology laboratories are typically smaller, laboratory-scale units designed for precise control and ease of use. These machines are crucial for research and development activities, enabling scientists to conduct experiments and studies on preserved biological samples. In Pharmaceutical Factories, freeze dryers play a critical role in the production of biopharmaceutical products, such as vaccines, antibodies, and other biologics. The lyophilization process is essential for preserving the stability and efficacy of these products, ensuring they remain effective during storage and transportation. Pharmaceutical freeze dryers are typically larger, industrial-scale units designed for high-volume production and stringent regulatory compliance. These machines are equipped with advanced features, such as automated control systems, monitoring sensors, and validation protocols, to ensure consistent and high-quality production. The use of freeze dryers in pharmaceutical factories helps manufacturers meet regulatory requirements, reduce production costs, and improve the shelf life of their products. Apart from Biology Laboratories and Pharmaceutical Factories, freeze dryers are also used in other specialized environments, such as food processing, cosmetics, and materials science. In the food processing industry, freeze dryers are used to preserve the quality and nutritional value of food products, such as fruits, vegetables, and meats. The lyophilization process helps remove moisture from the food, preventing spoilage and extending shelf life. In the cosmetics industry, freeze dryers are used to preserve the stability and efficacy of cosmetic products, such as creams, lotions, and serums. The lyophilization process helps maintain the quality and effectiveness of these products, ensuring they remain safe and effective for use. In materials science, freeze dryers are used to preserve the integrity and stability of various materials, such as polymers, ceramics, and metals. The lyophilization process helps remove moisture from these materials, preventing degradation and improving their performance. Overall, the Global Biopharma Freeze Dryer Machine Market plays a crucial role in various industries, enabling the preservation and stability of a wide range of products. The use of freeze dryers in Biology Laboratories, Pharmaceutical Factories, and other specialized environments helps ensure the quality and efficacy of biological samples, biopharmaceutical products, food, cosmetics, and materials. As the demand for these products continues to grow, the need for efficient and reliable freeze-drying technologies will also increase, driving the development and adoption of advanced freeze dryer machines in the market.

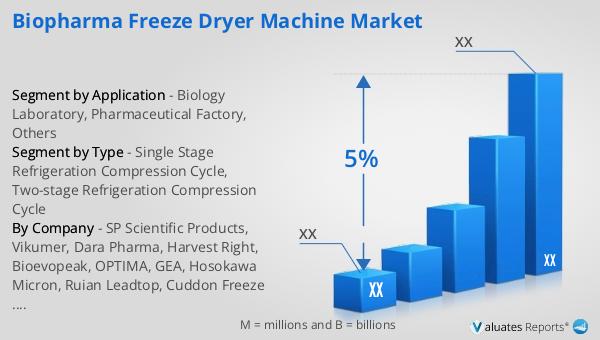

Global Biopharma Freeze Dryer Machine Market Outlook:

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, with an expected compound annual growth rate (CAGR) of 5% over the next six years. This growth trajectory highlights the increasing demand for pharmaceutical products and innovations in the industry. In comparison, the chemical drug market has shown a steady increase, growing from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This comparison underscores the robust expansion of the pharmaceutical sector, driven by advancements in drug development, increased healthcare spending, and the rising prevalence of chronic diseases. The growth in both the pharmaceutical and chemical drug markets reflects the ongoing efforts to meet the global demand for effective and innovative treatments. As these markets continue to expand, the need for advanced technologies and equipment, such as biopharma freeze dryer machines, will become increasingly important to ensure the quality, stability, and efficacy of pharmaceutical products.

| Report Metric | Details |

| Report Name | Biopharma Freeze Dryer Machine Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SP Scientific Products, Vikumer, Dara Pharma, Harvest Right, Bioevopeak, OPTIMA, GEA, Hosokawa Micron, Ruian Leadtop, Cuddon Freeze Dry, Labfreez Instruments Group, Sheyan Yiqi, Rotech Bioengineering, TOFFON, BIOCOOL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |