What is Global Automotive PVC Compound Market?

The Global Automotive PVC Compound Market refers to the worldwide industry focused on the production and distribution of polyvinyl chloride (PVC) compounds specifically designed for automotive applications. PVC compounds are versatile plastic materials that can be formulated to meet various performance requirements, making them ideal for use in the automotive sector. These compounds are used in a wide range of automotive components, including interior trims, exterior parts, and electrical wiring. The market for automotive PVC compounds is driven by the growing demand for lightweight, durable, and cost-effective materials in the automotive industry. Additionally, the increasing focus on sustainability and the need for materials that can be easily recycled have further boosted the demand for PVC compounds in automotive applications. The market is characterized by the presence of several key players who are continuously innovating to develop advanced PVC compounds that meet the evolving needs of the automotive industry.

Non-plasticized PVC Compound, Plasticized PVC Compound in the Global Automotive PVC Compound Market:

Non-plasticized PVC compounds, also known as rigid PVC, are widely used in the automotive industry due to their excellent mechanical properties and resistance to chemicals and weathering. These compounds are typically used in applications where rigidity and durability are essential, such as in the production of automotive exterior parts, including bumpers, grilles, and trim components. Non-plasticized PVC compounds offer high tensile strength and impact resistance, making them suitable for parts that need to withstand harsh environmental conditions and mechanical stress. Additionally, these compounds are resistant to UV radiation, which helps in maintaining the appearance and structural integrity of automotive parts over time. On the other hand, plasticized PVC compounds, also known as flexible PVC, are used in applications where flexibility and elasticity are required. These compounds are formulated by adding plasticizers to the PVC resin, which enhances their flexibility and makes them suitable for use in automotive interior components, such as dashboards, door panels, and seat covers. Plasticized PVC compounds offer excellent resistance to abrasion, chemicals, and UV radiation, making them ideal for interior applications that require both durability and aesthetic appeal. Moreover, these compounds can be easily molded into complex shapes, allowing for greater design flexibility in automotive interiors. In addition to interior components, plasticized PVC compounds are also used in the production of automotive wiring and cables. The flexibility and durability of these compounds make them suitable for use in electrical systems that require reliable performance under various operating conditions. Furthermore, plasticized PVC compounds are used in the production of automotive seals and gaskets, which require a combination of flexibility, durability, and resistance to chemicals and weathering. Overall, both non-plasticized and plasticized PVC compounds play a crucial role in the automotive industry by providing materials that meet the specific performance requirements of different automotive applications. The continuous development of advanced PVC compounds with improved properties is expected to further drive the growth of the global automotive PVC compound market in the coming years.

Automotive Interior, Electronic Wires, Other in the Global Automotive PVC Compound Market:

The usage of Global Automotive PVC Compound Market in automotive interiors is extensive and multifaceted. PVC compounds are used in the production of various interior components, including dashboards, door panels, seat covers, and floor mats. These materials offer a combination of durability, flexibility, and aesthetic appeal, making them ideal for use in automotive interiors. PVC compounds can be easily molded into complex shapes, allowing for greater design flexibility and customization in interior components. Additionally, these materials are resistant to abrasion, chemicals, and UV radiation, ensuring that the interior components maintain their appearance and functionality over time. In the production of electronic wires, PVC compounds are used as insulation materials due to their excellent electrical properties and resistance to heat and chemicals. The flexibility and durability of PVC compounds make them suitable for use in automotive wiring systems that require reliable performance under various operating conditions. PVC-insulated wires are used in a wide range of automotive applications, including lighting, power distribution, and communication systems. The use of PVC compounds in automotive wiring helps to ensure the safety and reliability of the electrical systems, which are critical for the overall performance of the vehicle. In addition to automotive interiors and electronic wires, PVC compounds are also used in other automotive applications, such as seals and gaskets. These components require materials that offer a combination of flexibility, durability, and resistance to chemicals and weathering. PVC compounds are ideal for use in seals and gaskets due to their ability to maintain their properties under various environmental conditions. The use of PVC compounds in these applications helps to ensure the proper sealing and protection of various automotive components, contributing to the overall performance and longevity of the vehicle. Overall, the usage of PVC compounds in the automotive industry is extensive and diverse, with these materials playing a crucial role in the production of various components that contribute to the performance, safety, and aesthetics of the vehicle.

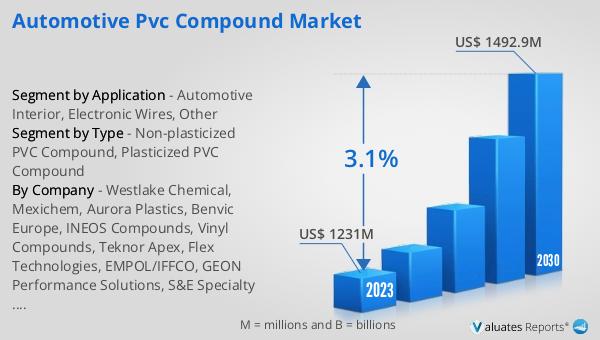

Global Automotive PVC Compound Market Outlook:

The global Automotive PVC Compound market was valued at US$ 1231 million in 2023 and is anticipated to reach US$ 1492.9 million by 2030, witnessing a CAGR of 3.1% during the forecast period from 2024 to 2030. This market outlook indicates a steady growth trajectory for the automotive PVC compound industry, driven by the increasing demand for lightweight, durable, and cost-effective materials in the automotive sector. The continuous innovation and development of advanced PVC compounds that meet the evolving needs of the automotive industry are expected to further fuel this growth. The market is characterized by the presence of several key players who are actively engaged in research and development to enhance the properties of PVC compounds and expand their applications in the automotive industry. The growing focus on sustainability and the need for materials that can be easily recycled are also contributing to the increasing demand for PVC compounds in automotive applications. As the automotive industry continues to evolve, the demand for high-performance materials that offer a combination of durability, flexibility, and aesthetic appeal is expected to drive the growth of the global automotive PVC compound market.

| Report Metric | Details |

| Report Name | Automotive PVC Compound Market |

| Accounted market size in 2023 | US$ 1231 million |

| Forecasted market size in 2030 | US$ 1492.9 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Westlake Chemical, Mexichem, Aurora Plastics, Benvic Europe, INEOS Compounds, Vinyl Compounds, Teknor Apex, Flex Technologies, EMPOL/IFFCO, GEON Performance Solutions, S&E Specialty Polymers, Sylvin Technologies, Konnark Polymer, Mazda Plastic, Thevinyl, ACTEGA, Avient Corporation, Hanwha, Kingfa, Alphagary, PT. Riken Indonesia, Orinko Advanced Plastics, Guangdong Silver Age Sci & Tech, China General Nuclear Power, MEGA Compound, SHENZHEN HOPEFINDER POLYMER |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |